On-line leakage intelligent monitoring system based on multi-parameter monitoring and monitoring method

An intelligent monitoring and multi-parameter technology, applied in the direction of signal transmission system, general control system, control/regulation system, etc., can solve problems such as lack of accuracy and timeliness of indirect judgment, blind maintenance methods, and equipment failure to repair in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

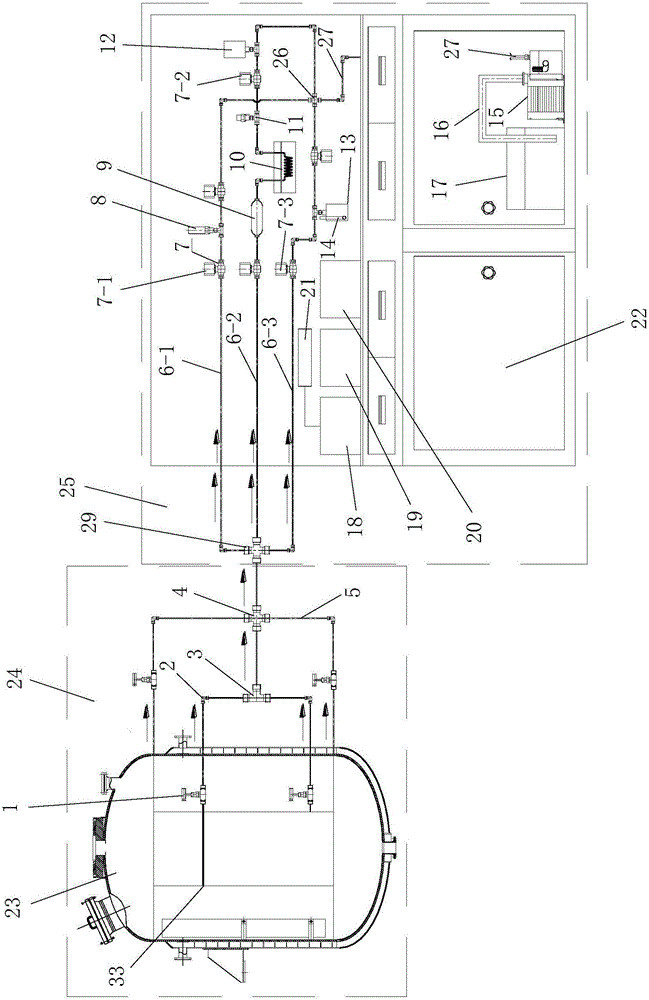

[0080] Such as figure 1 An on-line leakage intelligent monitoring system based on multi-parameter monitoring is shown, including a front-end leak detection connection device 24 installed on the monitored equipment 23 and a rear leakage monitoring device 25 connected to the front-end leak detection connection device 24;

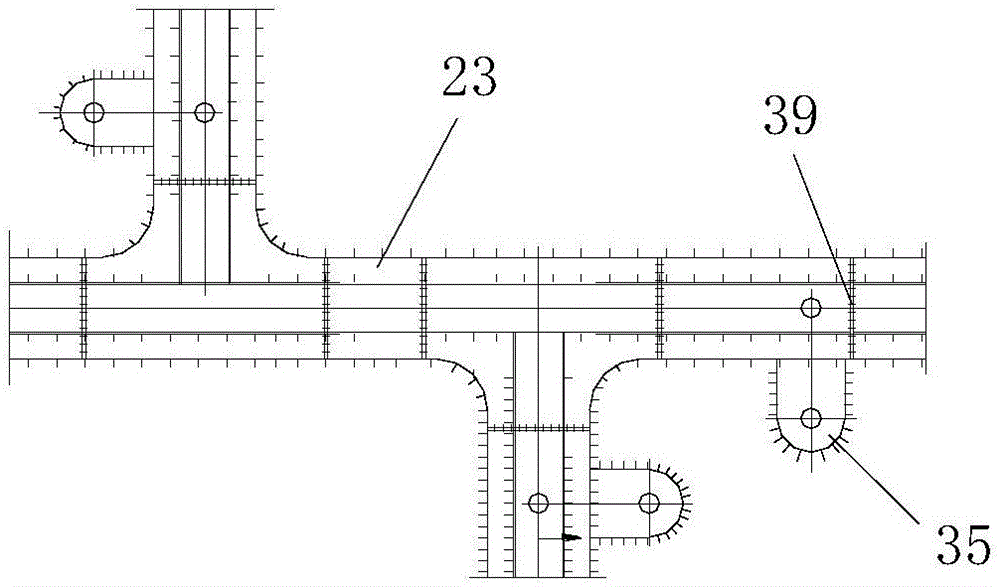

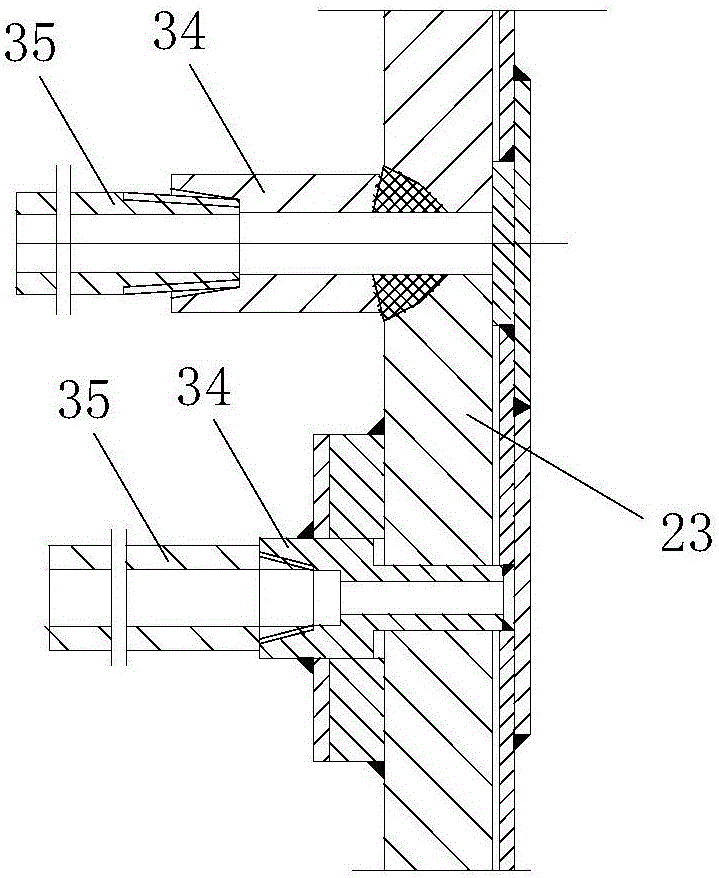

[0081] The front-end leak detection connection device 24 includes a plurality of leak detection connection pipes 5 and first connection joints 4 connected to the outlets of the plurality of leak detection connection pipes 5, and the monitored equipment 23 is provided with a plurality of monitoring devices. Holes 33, each of the monitoring holes 33 is connected to the inlet of one of the leak detection connecting pipes 5; a plurality of the monitoring holes 33 are respectively arranged on a plurality of monitoring areas of the monitored equipment 23;

[0082] combine Figure 4 , the rear leakage monitoring device 25 includes a pressure monitoring device, a gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com