Appropriate-temperature cutting real-time control method of composite material

A composite material and real-time control technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems of slow temperature adjustment speed and inability to directly control the temperature of the cutting area, so as to achieve the effect of ensuring high efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

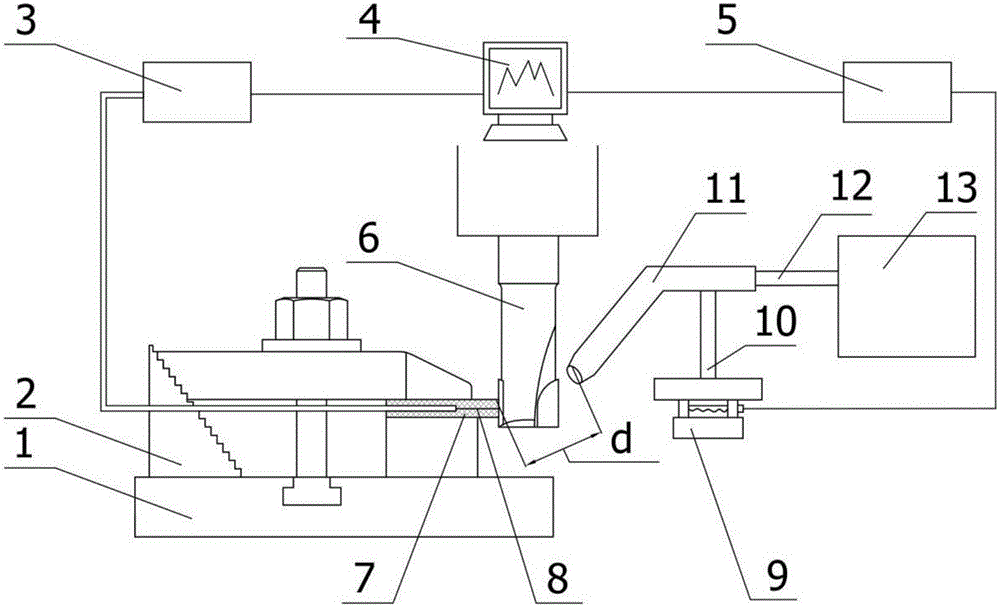

[0012] The implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings and technical solutions.

[0013] see figure 1 , the present invention uses the thermocouple 8 as the temperature detection device, and the ultra-low temperature cold air generator 12 as the temperature control device. The signal output end of the temperature detection device outputs the detection result to the computer 4 through the data line, and the computer 4 inputs the control data to the input end of the temperature control device through the data line to detect and control the temperature in real time. The specific steps of the method are as follows:

[0014] The first step is to build a real-time control system for temperature-appropriate cutting of composite materials

[0015] Install the clamping mechanism 2 on the CNC machine tool table 1, fix the composite material 7 in the clamping mechanism 2, install a thermocouple 8 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com