Multivariable-based batch chemical production process dynamic on-line monitoring method and device

A technology for chemical production and production process, applied in the fields of chemical industry, metallurgy, and manufacturing, it can solve problems such as the inability to realize multi-dimensional comprehensive monitoring, and achieve the effect of improving the one-time pass rate of products and improving control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

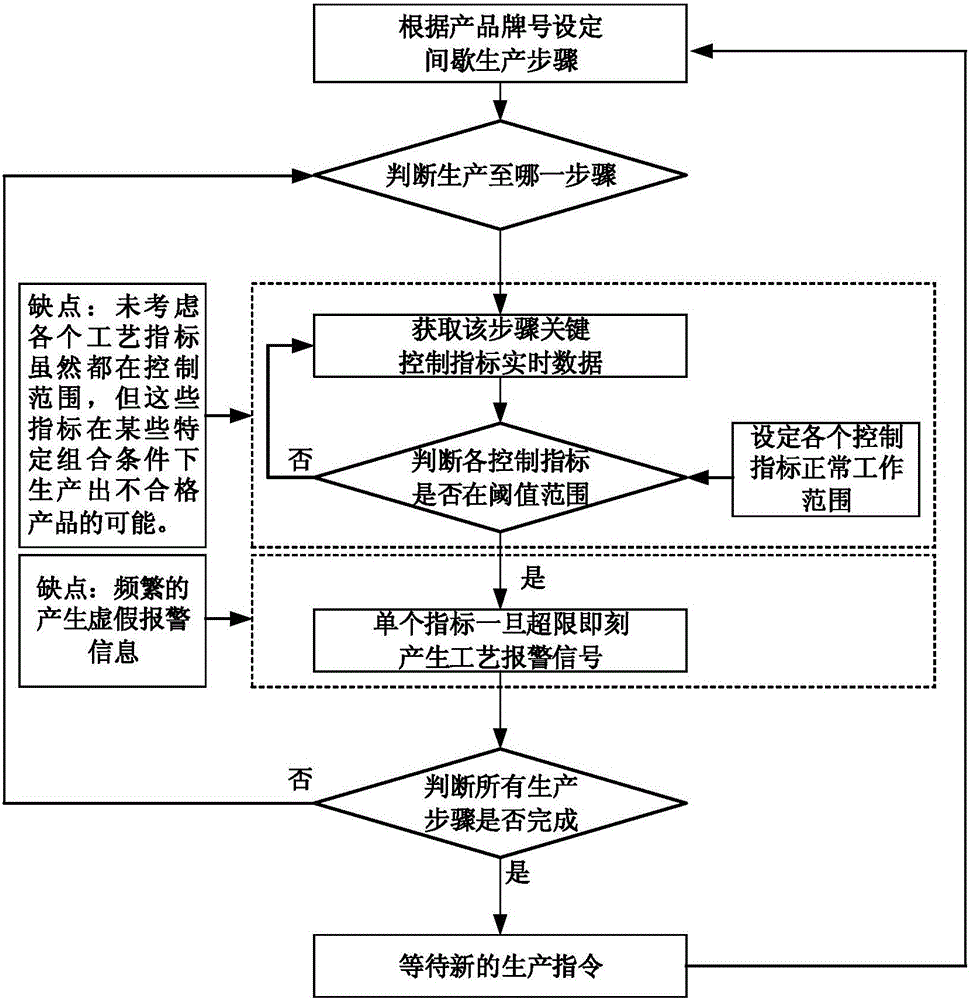

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

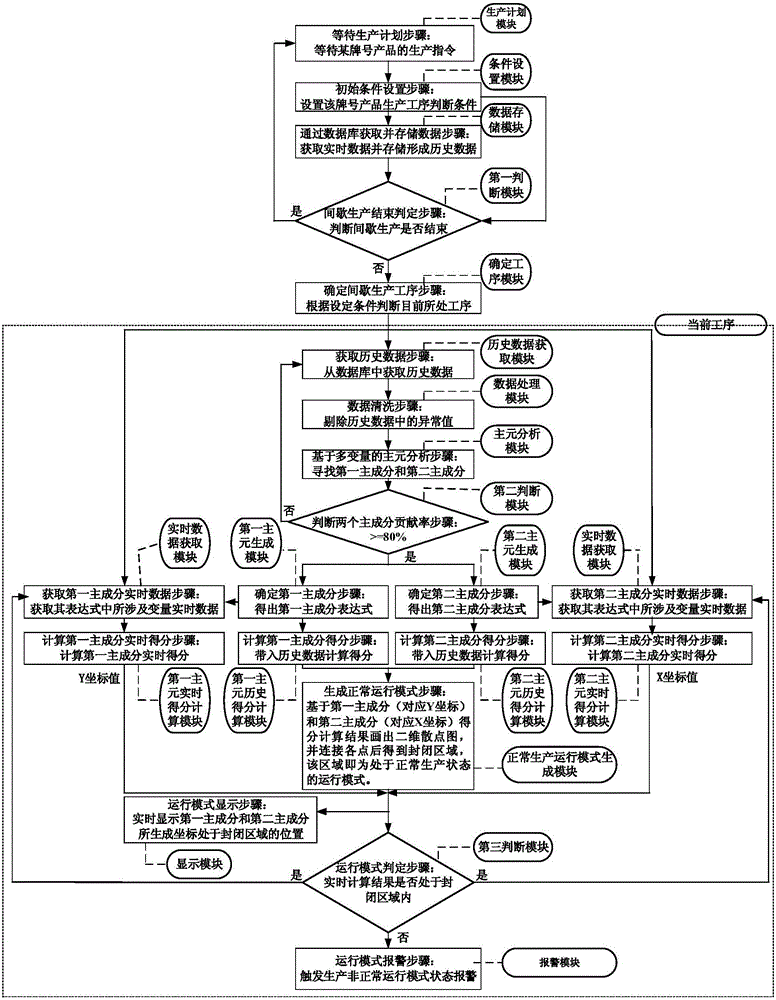

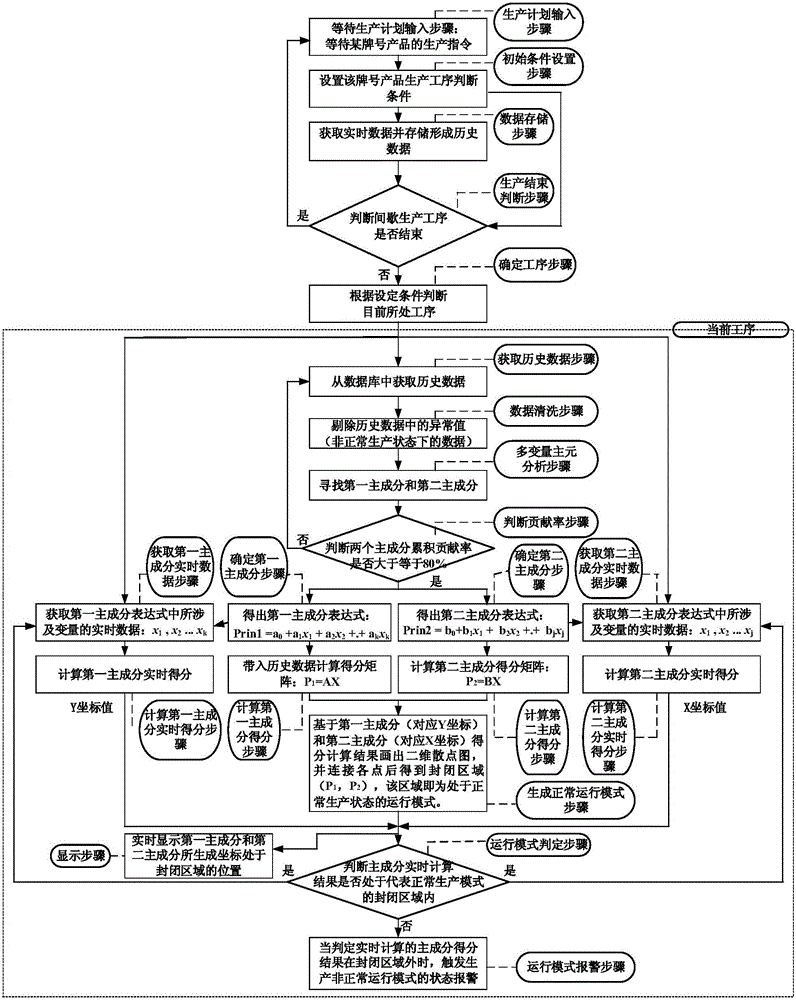

[0036] see figure 2 , which shows the dynamic on-line monitoring method of batch chemical production process based on multivariable of the present invention, and this monitoring method comprises the following steps:

[0037] Waiting for the production planning step, waiting for the production order of a certain brand product;

[0038] The initial condition setting step is to set the judgment conditions of the production process of the brand product after receiving the production instruction;

[0039] The step of obtaining and storing data through the database, using the functions of the real-time database to obtain real-time data and store and form historical data;

[0040] The step of judging the end of intermittent production is to judge whether the intermittent production process of the brand is over accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com