Battery pack automatic assembly equipment

An automatic assembly and battery pack technology, applied in the direction of assembly machines, battery assembly machines, secondary battery manufacturing, etc., can solve the problems of low automation and low production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

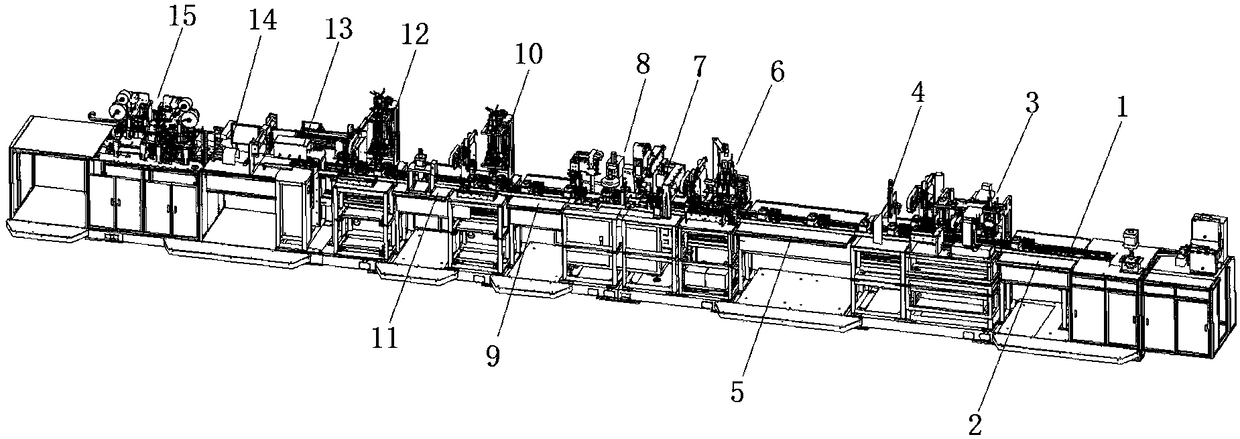

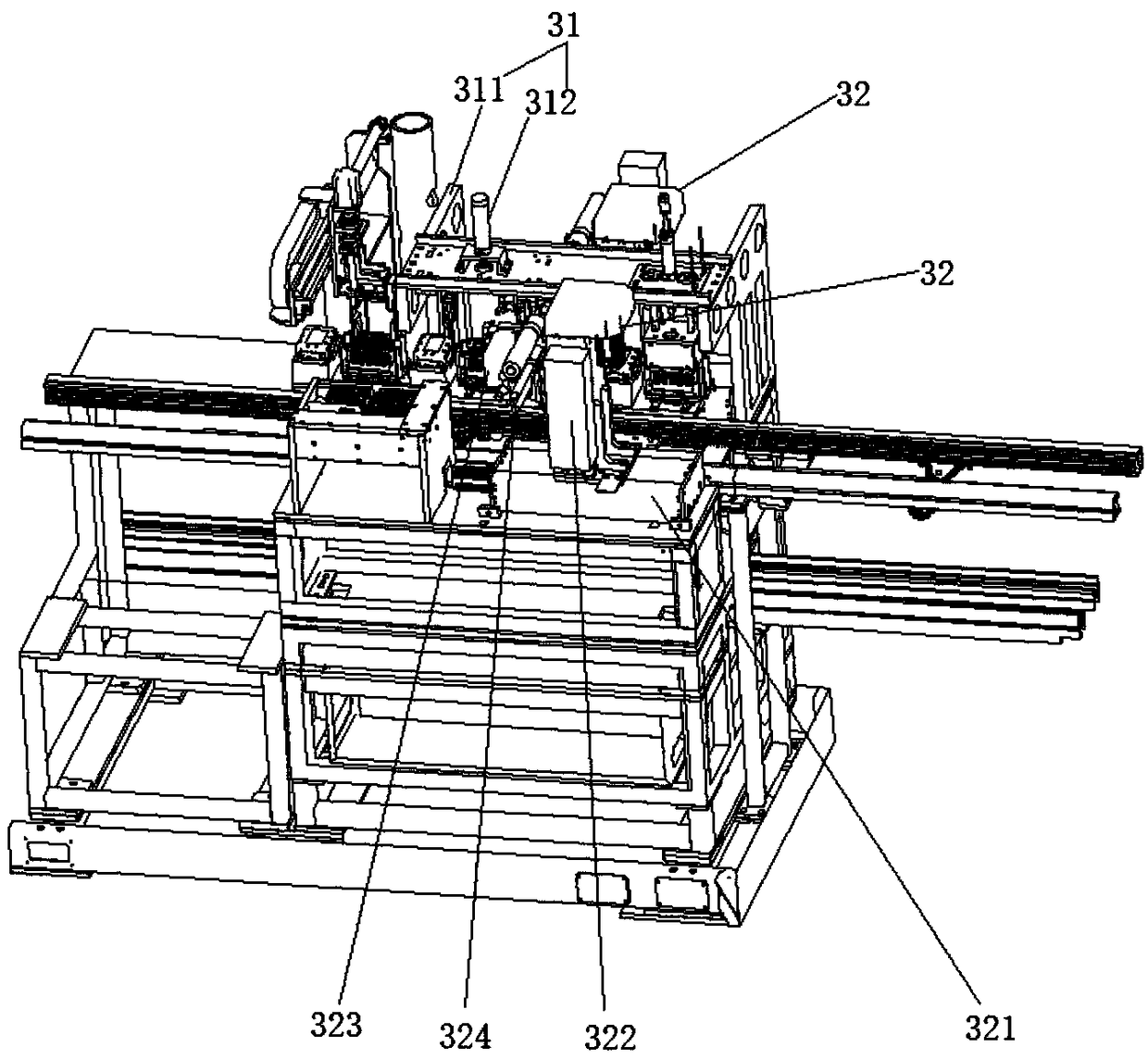

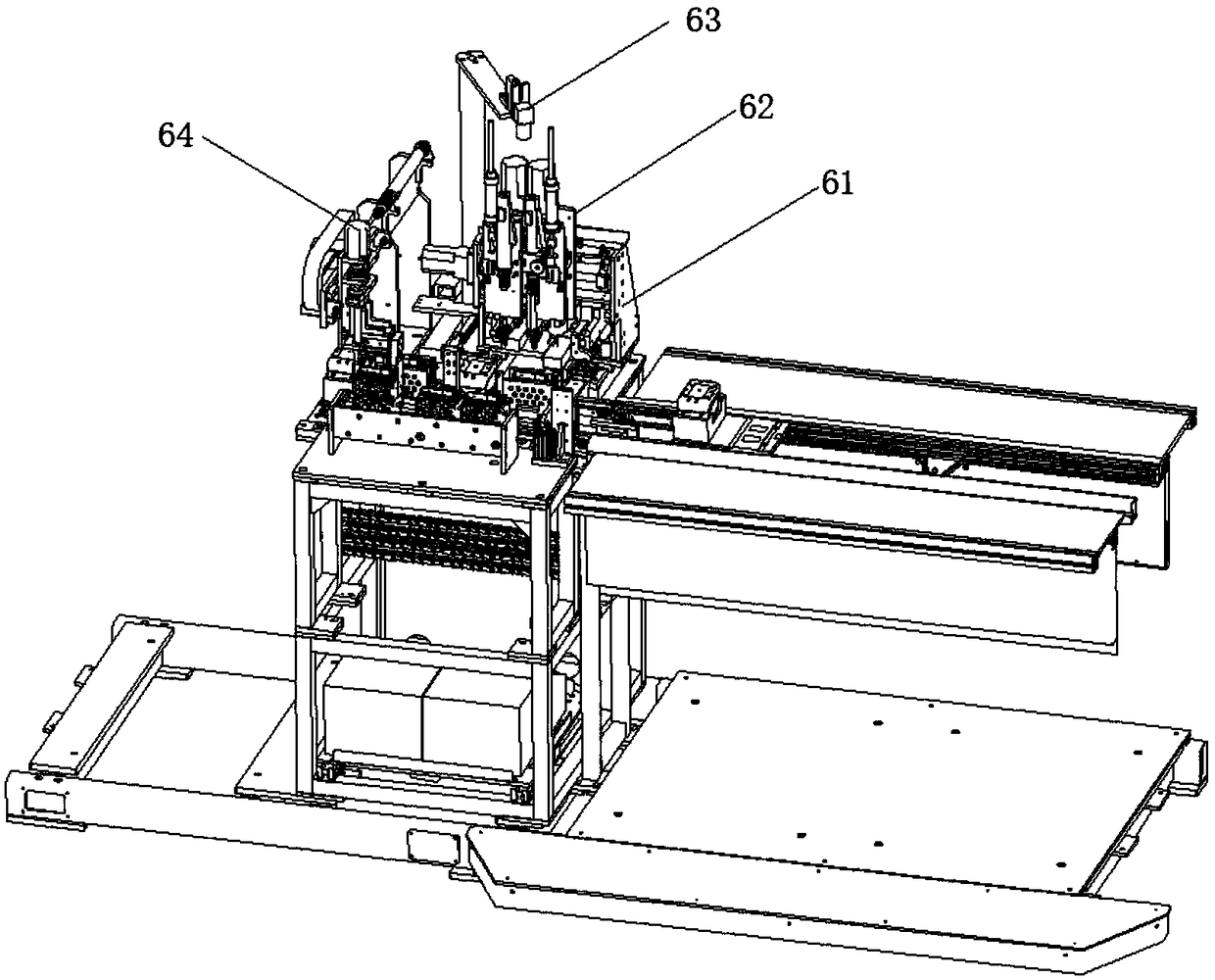

[0025] refer to Figure 1 to Figure 7 , an automatic assembly equipment for battery packs, comprising a carrier conveying line 1, and devices sequentially arranged along the conveying direction of the carrier conveying line 1 to pack a plurality of batteries into a plastic frame and install a plurality of metal sheets into the plastic frame The first operating station 2, the first butt welding machine used to weld the metal sheet and the positive and negative terminals of the battery together, the internal resistance tester 4, used to put the circuit board into the plastic frame The second operating station 5, the circuit board screw machine 6, the second butt welding machine 7 for welding the end of the metal sheet and the input terminal of the circuit board together, the solder detection integrated machine 8, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com