Transparent broadband electromagnetic absorber based on double-layer conductive film

A conductive film and transparent conductive film technology, applied in electrical components, antennas, etc., can solve the problem of narrow application range of wave absorbers, and achieve the effect of ensuring broadband wave absorption effect, reducing thickness and weight, and good chemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

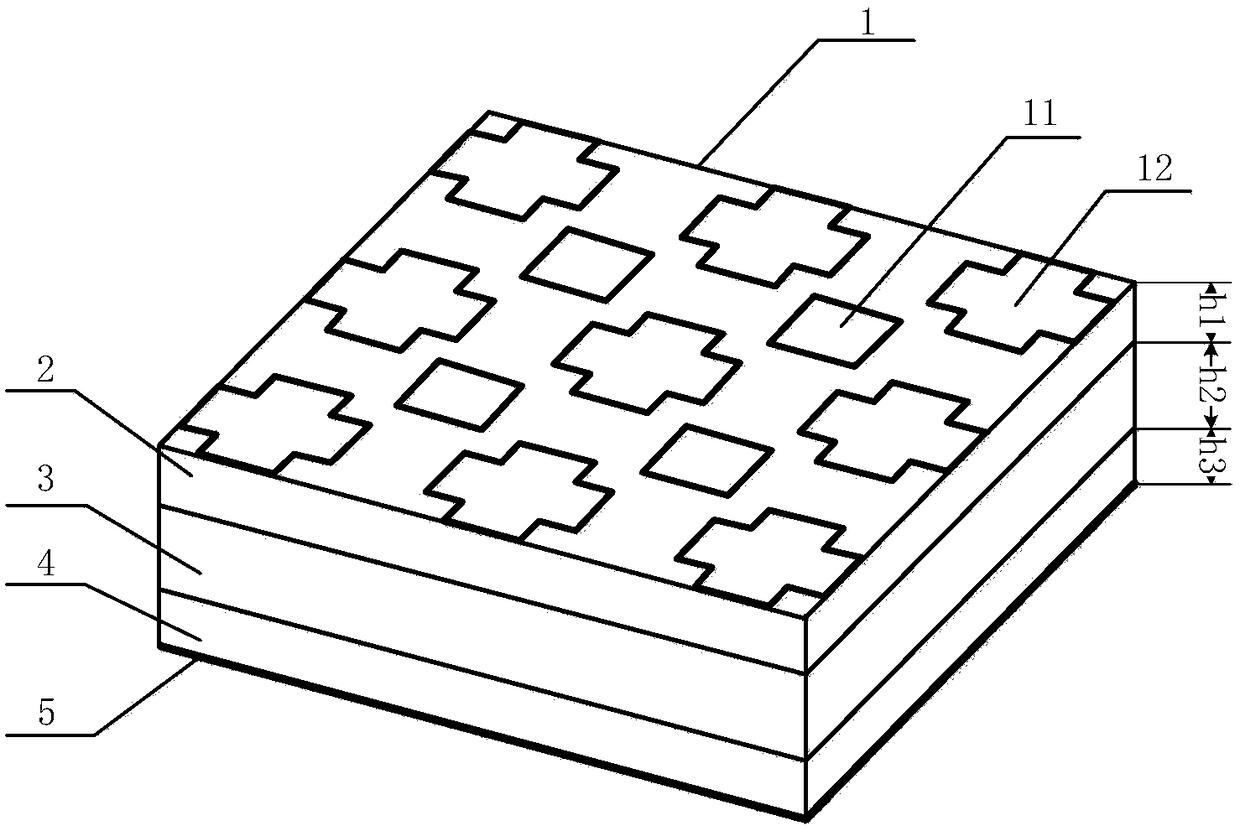

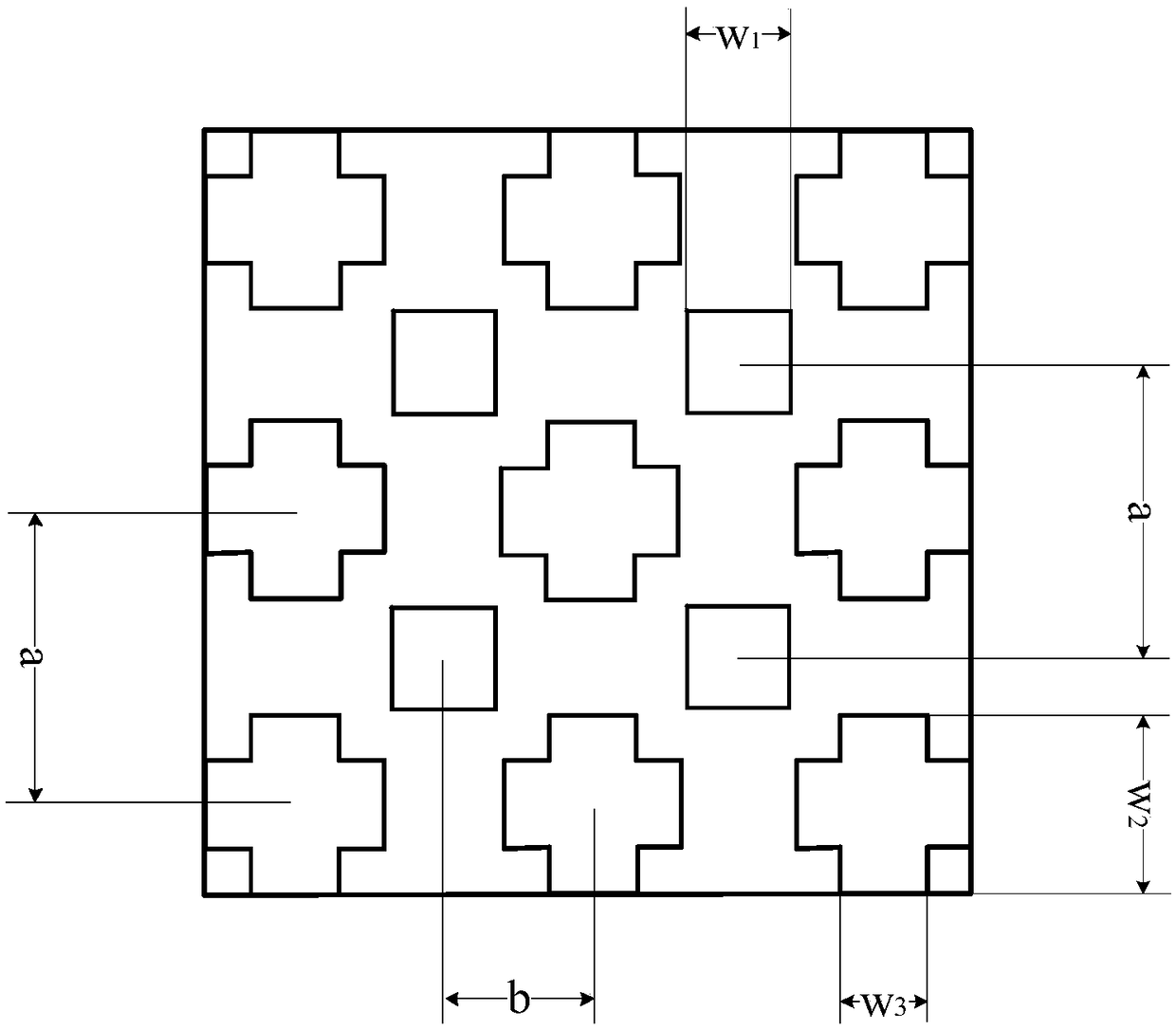

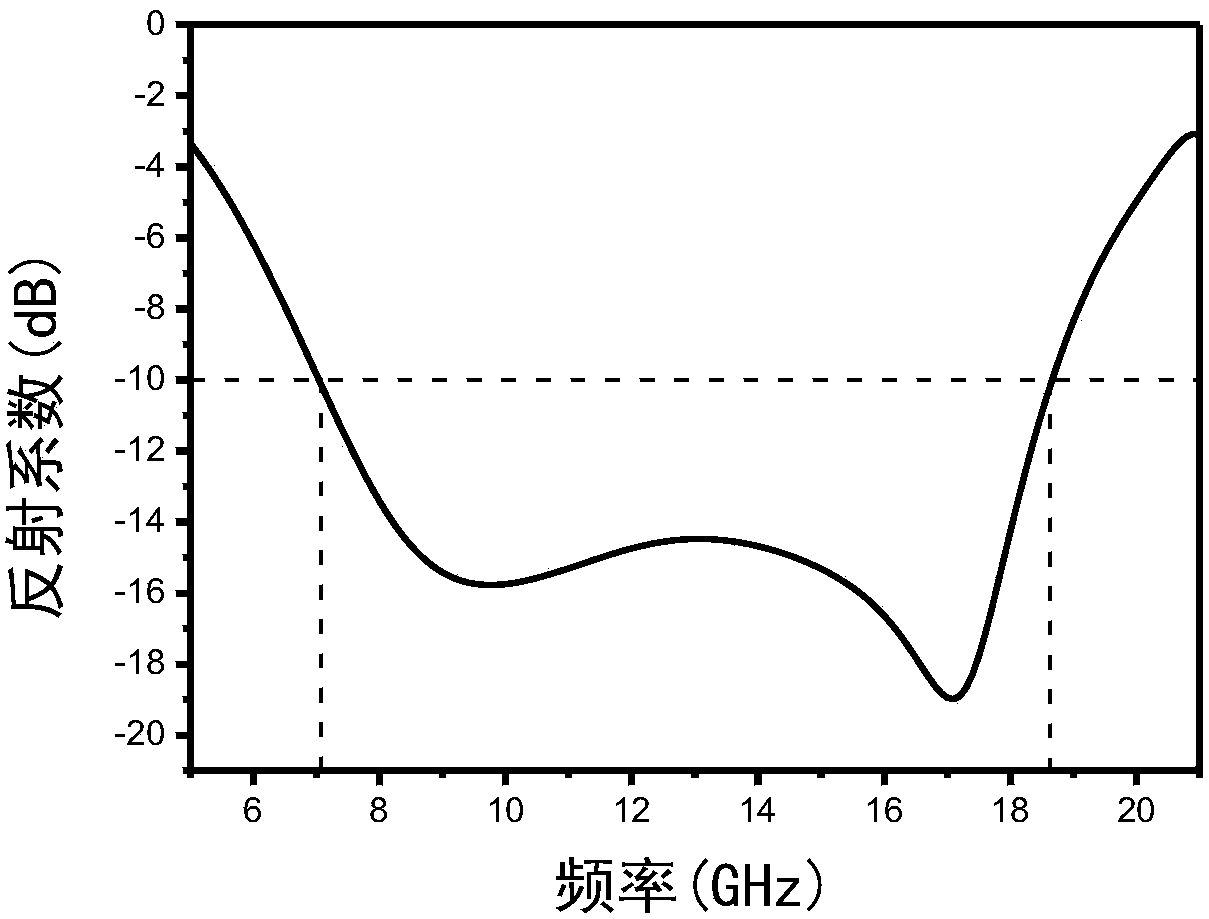

[0024] refer to figure 1 , including a conductive film 1, a first dielectric layer 2, a second dielectric layer 3, a third dielectric layer 4 and a bottom plate 5, wherein the three dielectric layers 2, 3 and 4 are arranged from top to bottom to form a stacked dielectric layer The bottom plate 5 is printed on the lower surface of the third dielectric layer 4, and the conductive film 1 is printed on the upper surface of the first dielectric layer 2, and the conductive film 1 is an array composed of m×n square transparent conductive films 11 and (m +1)×(n+1) arrays composed of cross-shaped transparent conductive films 12 are composited. In this embodiment, an array composed of 2×2 square transparent conductive films 11 and 3×3 cross-shaped transparent conductive films are used An array composed of 12, its specific structure is as follows figure 2 shown.

[0025] Both the first dielectric layer 2 and the third dielectric layer 4 adopt a relative permittivity ε r1 2.7 square p...

Embodiment 2

[0031] Embodiment 2 has the same structure as Embodiment 1, and the following parameters have been adjusted:

[0032] Both the first dielectric layer 2 and the third dielectric layer 4 adopt a relative permittivity ε r1 A square polymethacrylate (PMMA) dielectric plate of 4, wherein the thickness h of the first dielectric layer 2 1 =1mm, the thickness h of the third dielectric layer 4 3 =1mm; the thickness h of the second dielectric layer 3 is selected 2 2mm, relative permittivity ε r2 3.9 square quartz glass dielectric plate; square conductive film 11 and cross-shaped conductive film 12 adopt square resistance R S1 The graphene film is 100Ω / sq, and the bottom layer 5 adopts square resistance R S It is a square indium tin oxide film of 10Ω / sq, and the side length of the square conductive film 11 is W 1 is 9mm.

Embodiment 3

[0034] The structure of embodiment 3 is identical with the structure of embodiment 1, and following parameter has been adjusted:

[0035] Both the first dielectric layer 2 and the third dielectric layer 4 adopt a relative permittivity ε r1 is a square polymethacrylate (PMMA) dielectric plate of 2, wherein the thickness h of the first dielectric layer 2 1 =2.5mm, the thickness h of the third dielectric layer 4 3 =2.5mm; the thickness h of the second dielectric layer 3 is selected 2 2.5mm, relative permittivity ε r2 2.7 square polycarbonate dielectric plate; square conductive film 11 and cross-shaped conductive film 12 adopt square resistance R S1 It is a graphene film of 60Ω / sq, and the bottom plate 5 adopts square resistance R S A square indium tin oxide film of 5Ω / sq.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com