Elastic sheet assembly for vibration motors and linear vibration motor

A vibration motor and shrapnel technology, applied in electrical components, electromechanical devices, etc., can solve the problems of large occupied space, complex structure and manufacturing process, loss of avoidance function, etc., and achieve small occupied space, low manufacturing cost, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

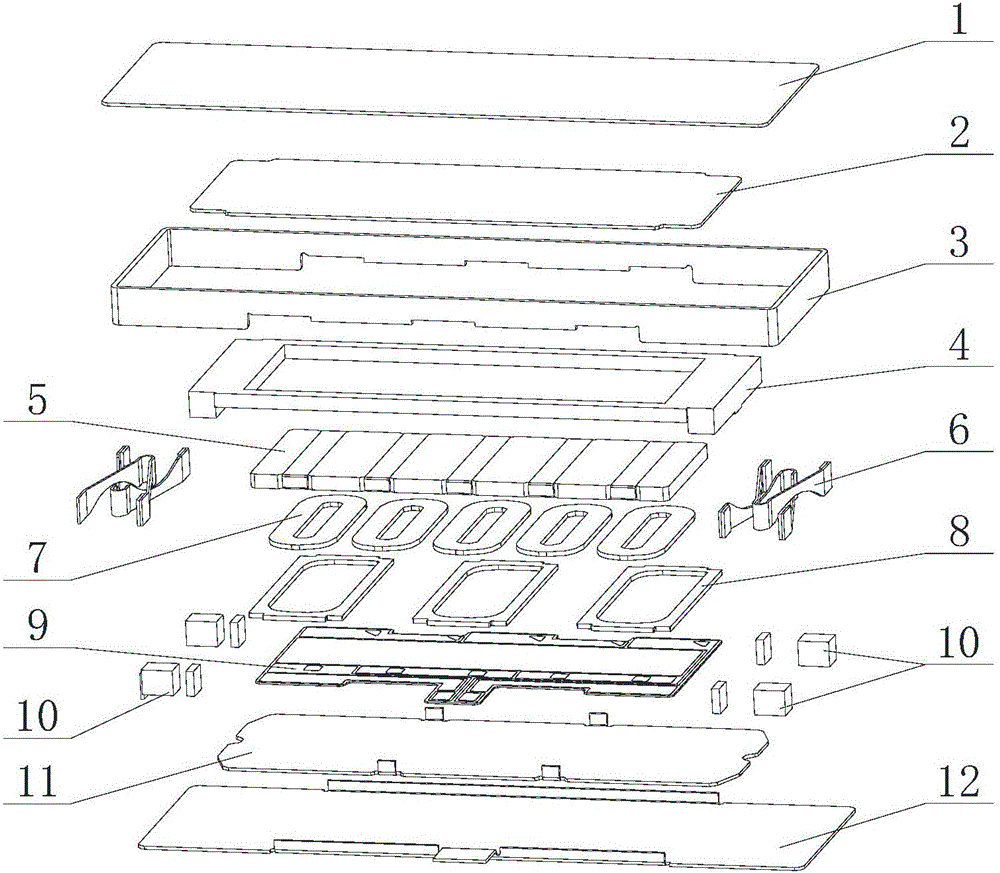

[0034] Such as Figure 6 , Figure 7 , Figure 8 , Figure 9 Shown is one of the embodiments of the present invention, in this embodiment, the shrapnel assembly used for the vibration motor includes two V-shaped shrapnel 6, the V-shaped shrapnel 6 is provided with two elastic arms 6-1, the elastic arms 6- 1 is a flat leaf spring, and the height of the elastic arm 6-1 is equal to the height of the shrapnel 6, that is Figure 8 Shown in H. The elastic arm 6-1 is provided with an arc-shaped notch, which constitutes a Z-axis avoidance groove, and two V-shaped shrapnel 6 are buckled up and down through the arc-shaped notch, and the V-shaped openings are facing oppositely. After buckling, the height of the shrapnel assembly is equal to The height of the elastic arm 6-1.

[0035] Such as Figure 6 , Figure 10 As shown, a U-shaped bend 6-3 is arranged between the two elastic arms 6-1. The V-shaped shrapnel in the prior art is still V-shaped at the bend, and the resistance to ...

Embodiment 2

[0041] Such as Figure 11 As shown, in this embodiment, the two V-shaped shrapnels are connected and combined with the openings facing the same way, and are welded and fixed by the adjacent welding plane 6-2 to form a shrapnel unit, and the two shrapnel units are buckled up and down through the arc-shaped notch , the V-shaped openings are facing oppositely, and the height of the elastic piece assembly after buckling is equal to the height of the elastic arm 6-1.

[0042] Adopting such a design can greatly improve the elastic force of the shrapnel assembly.

Embodiment 3

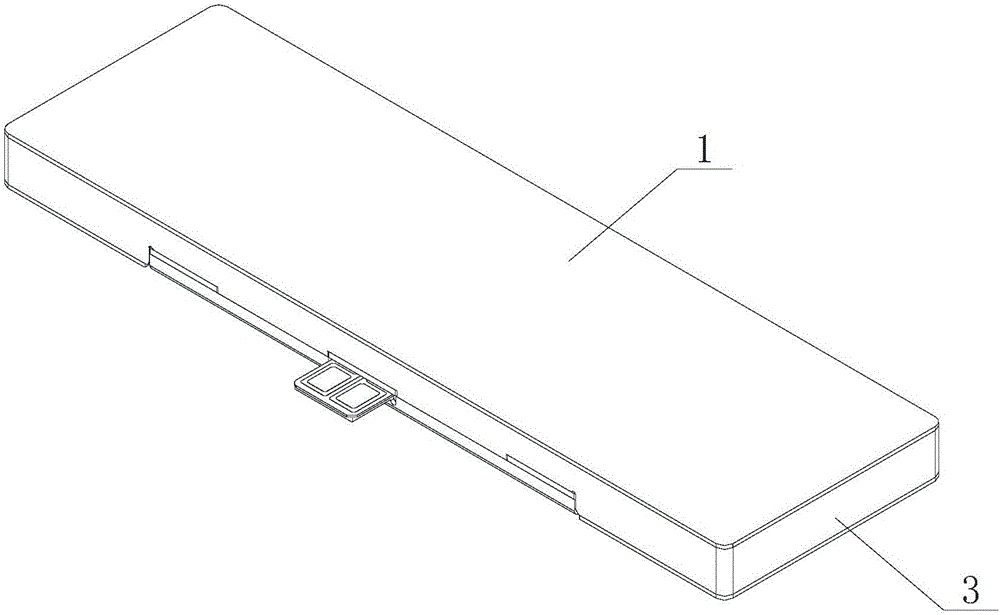

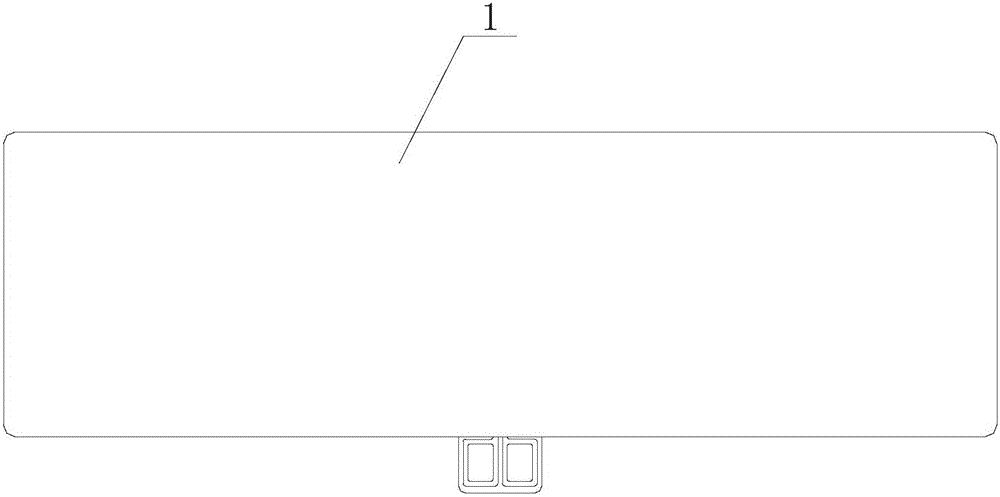

[0044] Such as image 3 , Figure 4 , Figure 5 As shown, in this embodiment, a linear vibration motor includes a mass block 2 that reciprocates along the X-axis direction, and the shrapnel assembly described in Embodiment 1 is arranged on both sides of the mass block 2, or, on the mass block 2 The shrapnel components described in Embodiment 2 may also be provided on both sides.

[0045] Since the height of the shrapnel assembly is very small, the vibration motor can be fully flattened, which is conducive to the improvement of lightness and thinness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com