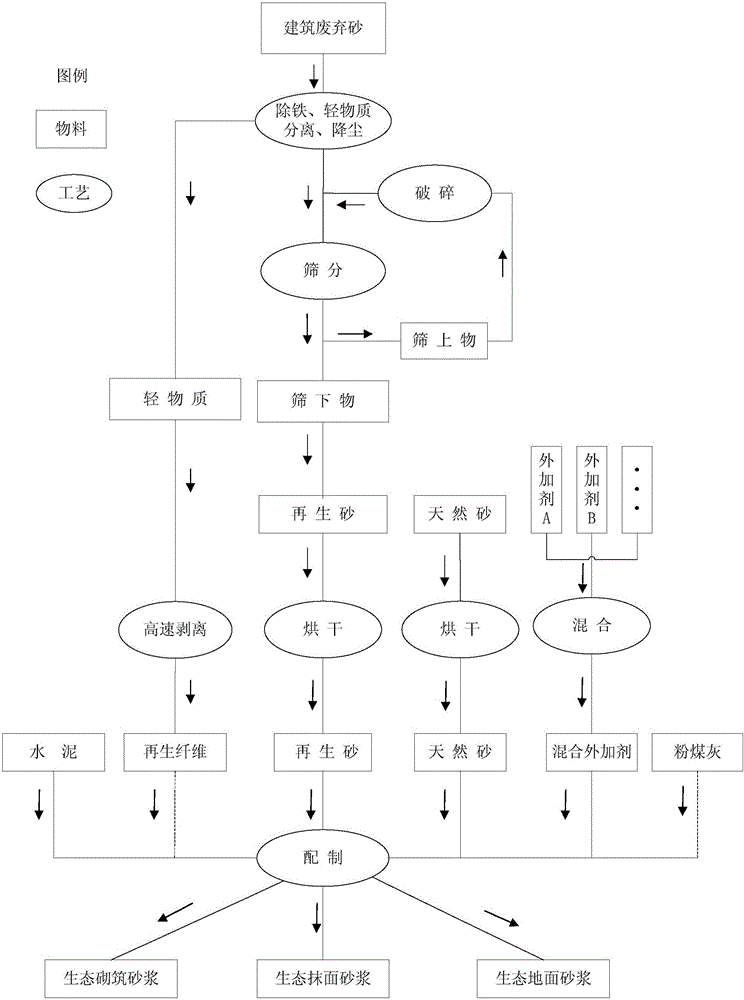

Production process of ecological dry-mixed mortar

A dry-mixed mortar and production process technology, applied in the field of building materials and resource recycling, can solve the problems of land occupation, low utilization rate, pollution of water and soil resources and atmospheric environment, etc., achieving low cost, simple preparation process, and alleviation of resources and environment. effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A kind of M10 ecological masonry dry-mix mortar described in the present invention: 205kg of ordinary portland cement (P·O42.5), 68kg of secondary fly ash, 540kg of recycled sand, 810kg of natural sand, hydroxypropyl methylcellulose 81g, sodium lauryl sulfate 65g. Add water and mix, and the water retention rate of the prepared ecological masonry dry-mix mortar is 92.1%, the consistency is 55mm, and the 28d compressive strength is 12.5MPa.

Embodiment 2

[0065] A kind of M5 ecological plastering dry-mixed mortar described in the present invention: Ordinary Portland cement (P·O42.5) 170kg, Ⅱ class fly ash 55kg, recycled sand 675kg, natural sand 675kg, hydroxypropyl methylcellulose 66g, 1.6kg redispersible latex powder, 110g defoamer, 1kg regenerated fiber. Add water and mix, and test the water retention rate of the prepared ecological plastering dry-mixed mortar is 95.1%, the consistency is 55mm, the 28d compressive strength is 6.3MPa, and the 14d bond tensile strength is 0.30MPa.

Embodiment 3

[0067] A kind of M25 ecological ground dry-mix mortar described in the present invention: Ordinary Portland cement (P·O42.5) 375kg, recycled sand 405kg, natural sand 945kg, hydroxypropyl methylcellulose 179g, redispersible latex powder 2.6 kg, water reducer 1.8kg, defoamer 135g. Add water and mix, and test the wear resistance of the prepared ecological ground dry-mix mortar 0.41g, 28d compressive strength 32.4MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com