Low temperature crack resistance test method and equipment of building materials

A technology of anti-crack performance and test method, which is applied in the preparation of test samples, and the use of stable tension/pressure to test the strength of materials, etc., can solve the problems of qualitative but not quantitative, and achieve low cost, simplified measurement system and no The effect of the power frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

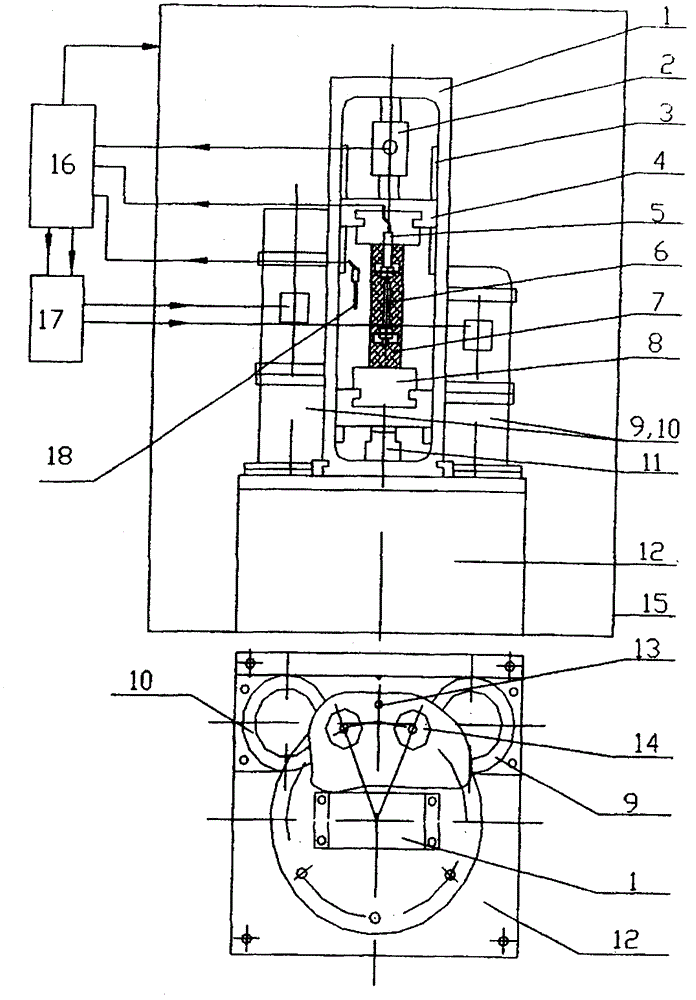

[0021] The specific implementation of the testing method and equipment of the present invention will be further described in conjunction with the accompanying drawings.

[0022] see figure 1 : In the ambient temperature control box 15, the square column-shaped test piece 6 is fixed on the upper chuck 4 and the lower chuck 8 at both ends of the rigid frame 1 of the freeze-break testing machine, and one end has a leading screw and a force sensor for adjusting and eliminating the gap 2. The other end is a stretching mechanism driven by the first servo reduction motor 10 through a transmission system with a large reduction ratio, and the stretching speed is steplessly adjustable. A pair of displacement sensors 5 with high precision (resolution < 0.001 mm, linearity < 0.002 mm) and a sensor fixture 7 made of a material with a small linear expansion coefficient are fixed on both sides of the test piece 6. The "temperature-displacement curve" of the cooling process is measured on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com