Method for processing sweet potato leaf powder

A processing method and technology of sweet potato leaves, applied in the field of sweet potato leaf powder processing, to achieve the effects of increasing nutrition and color varieties, easy promotion, and improving health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

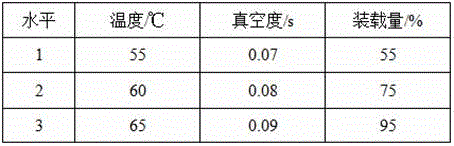

[0010] A processing method of sweet potato leaf powder includes the steps of washing, drying, crushing and sieving fresh leaves; wherein the drying is vacuum drying, the drying temperature is 50-70°C, the vacuum degree is 0.07-0.09MPa, and the drying time is 6 -11h, the loading capacity is 55-95%; preferably, the drying temperature is 60°C, the vacuum degree is 0.09MPa, the drying time is 8h, and the loading capacity is 75%.

[0011] In order to make the content of the present invention easier to understand, the technical solution of the present invention will be further described below in combination with specific methods.

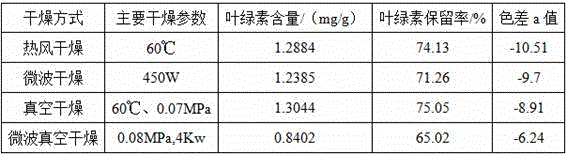

[0012] 1. The effect of different drying methods on sweet potato leaves

[0013] The washed fresh sweet potato leaves were dried by hot air drying, microwave drying, vacuum drying and microwave vacuum drying, respectively. The drying results are shown in Table 1.

[0014] Table 1 Effects of different drying methods on sweet potato leaf color

[0015]

[0016] It c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com