Method for preparing organic hydrogenation catalyst based on noble metal nanoparticles

A nanoparticle and hydrogenation reaction technology, applied in the field of nanomaterials, can solve the problems of complex catalyst preparation methods and unoptimized catalytic activity, and achieve excellent catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

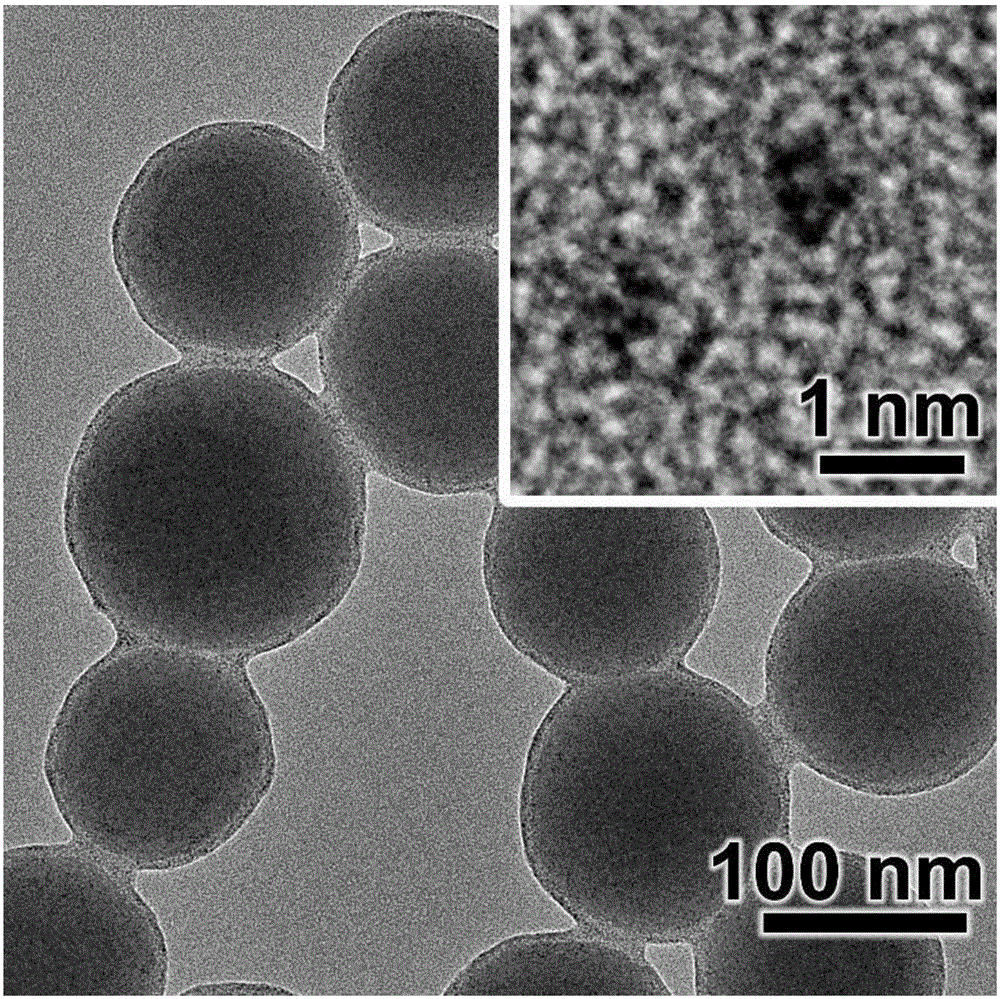

[0039] 1) Preparation of ~100nm silica spheres: Add 15mL tetraethyl orthosilicate (TEOS) into a mixed solution consisting of 294mL ethanol, 24mL deionized water and 7.5mL ammonia solution (28wt%), and stir at room temperature for 12 hours. The silica spheres were centrifuged and redispersed into 50 mL of isopropanol (HPLC grade), then added 0.1 mL of 3-amino-4-hydroxybenzenesulfonic acid (APS), refluxed at 70 °C for 10 hours, then centrifuged, and the solid part was used Wash with a mixture of absolute ethanol and water, and redisperse in 150 ml of absolute ethanol to obtain an amino-modified substrate dispersion.

[0040] 2) Prepare an ultra-small platinum nanoparticle film layer on the surface of the silicon sphere. Take 3mL of the amino-modified substrate dispersion prepared in step 1), add it to a mixture of 20mL absolute ethanol, 125mL deionized water and 0.2mL ammonia solution (28wt%), add 0.3g dodecyl Sodium benzenesulfonate (SDBS), stirred evenly to obtain the base mi...

Embodiment 2

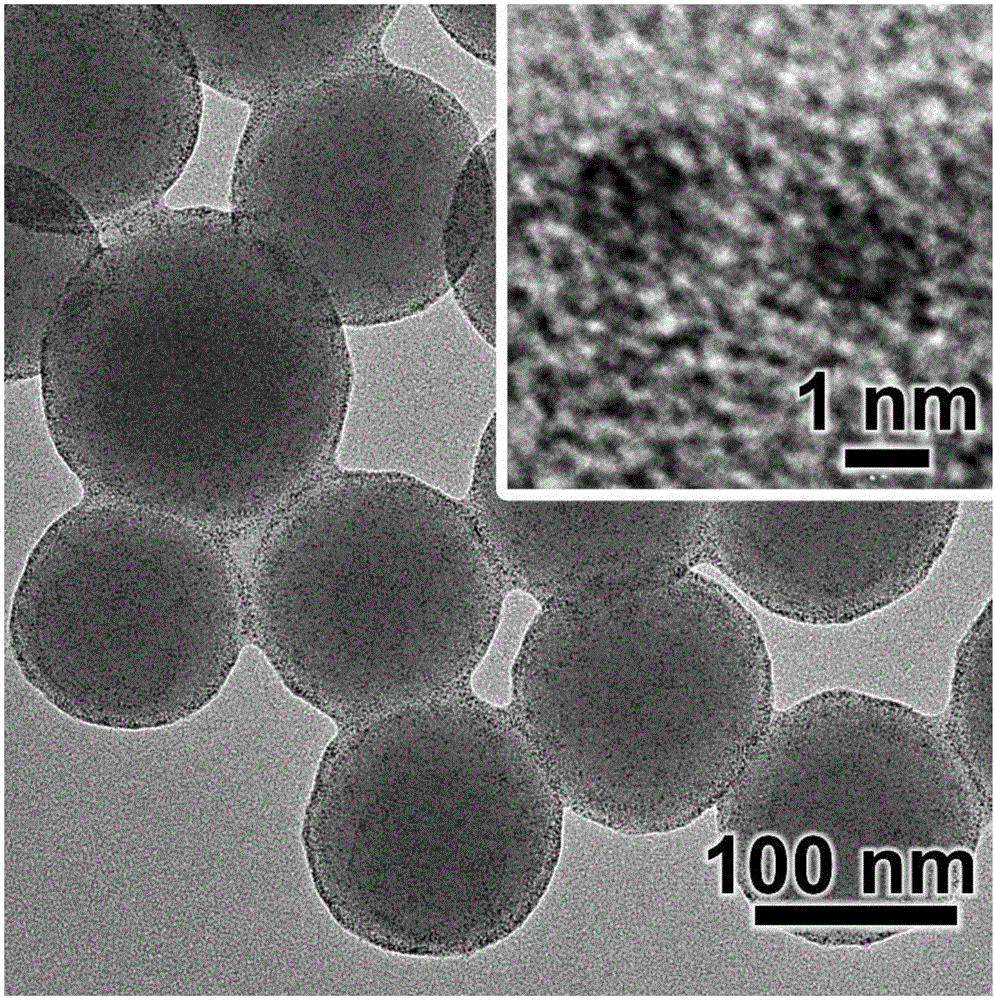

[0043] 1) Preparation of ~100nm silica spheres: Add 15mL tetraethyl orthosilicate (TEOS) into a mixed solution consisting of 294mL ethanol, 24mL deionized water and 7.5mL ammonia solution (28wt%), and stir at room temperature for 12 hours. The silica spheres were centrifuged and redispersed into 50 mL of isopropanol (HPLC grade), then added 0.1 mL of 3-amino-4-hydroxybenzenesulfonic acid (APS), refluxed at 70 °C for 10 hours, then centrifuged, and the solid part was used Wash with a mixture of absolute ethanol and water, and redisperse in 150 ml of absolute ethanol to obtain an amino-modified substrate dispersion.

[0044] 2) Prepare an ultra-small platinum nanoparticle film layer on the surface of the silicon sphere. Take 3mL of the amino-modified substrate dispersion prepared in step 1), add it to a mixture of 20mL absolute ethanol, 125mL deionized water and 0.2mL ammonia solution (28wt%), add 0.3g dodecyl Sodium benzenesulfonate (SDBS), stirred evenly to obtain the base mi...

Embodiment 3

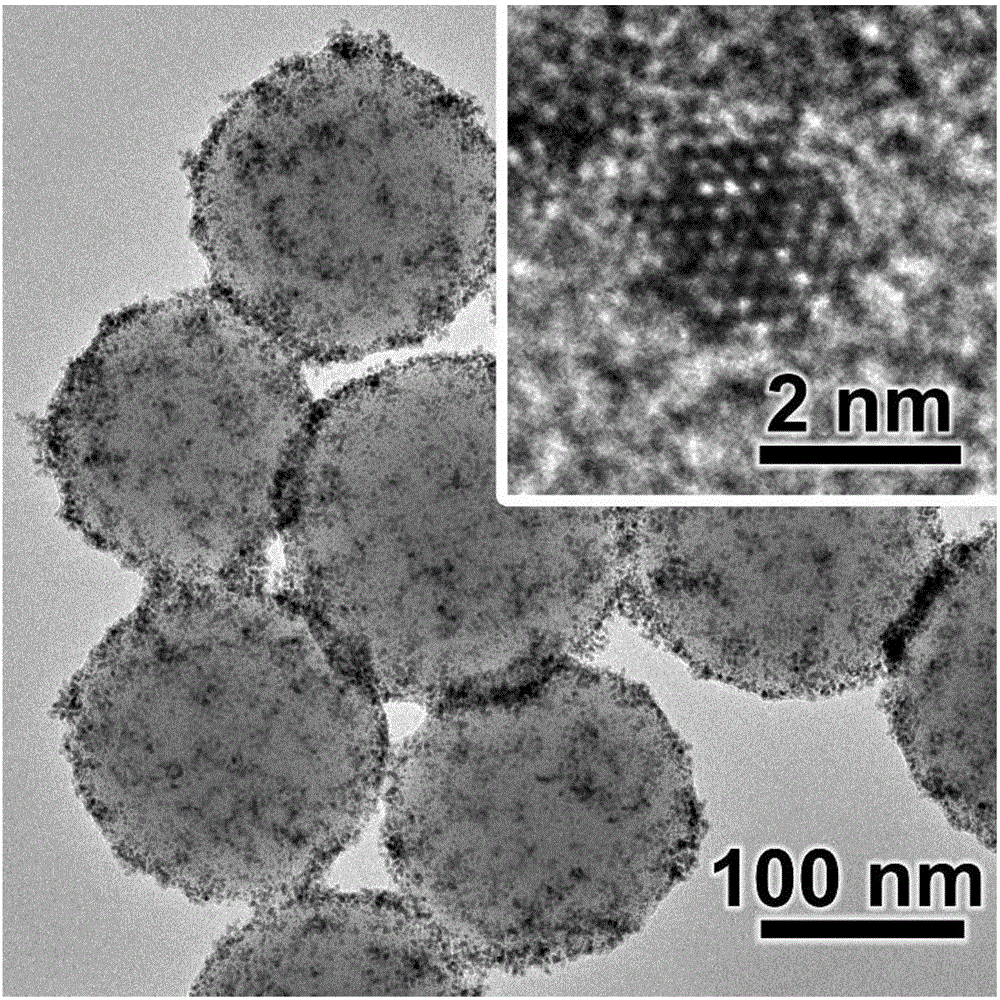

[0047] 1) Preparation of ~100nm silica spheres: Add 15mL tetraethyl orthosilicate (TEOS) into a mixed solution consisting of 294mL ethanol, 24mL deionized water and 7.5mL ammonia solution (28wt%), and stir at room temperature for 12 hours. The silica spheres were centrifuged and redispersed into 50 mL of isopropanol (HPLC grade), then added 0.1 mL of 3-amino-4-hydroxybenzenesulfonic acid (APS), refluxed at 70 °C for 10 hours, then centrifuged, and the solid part was used Wash with a mixture of absolute ethanol and water, and redisperse in 150 ml of absolute ethanol to obtain an amino-modified substrate dispersion.

[0048] 2) Prepare an ultra-small platinum nanoparticle film layer on the surface of the silicon sphere. Take 3mL of the amino-modified substrate dispersion prepared in step 1), add it to a mixture of 20mL absolute ethanol, 125mL deionized water and 0.2mL ammonia solution (28wt%), add 0.3g dodecyl Sodium benzenesulfonate (SDBS), stirred evenly to obtain the base mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com