Ceramic roller for crushing lithium battery raw material and ceramic twin-roller machine

A raw material crushing and ceramic roller technology, which is applied in the direction of grain processing, etc., can solve the problems of the ceramic roller groove being easily worn, the ceramic roller’s service life is short, and the crushing efficiency is low, so as to improve the raw material crushing efficiency, increase the amount of crushing, and improve The effect of crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

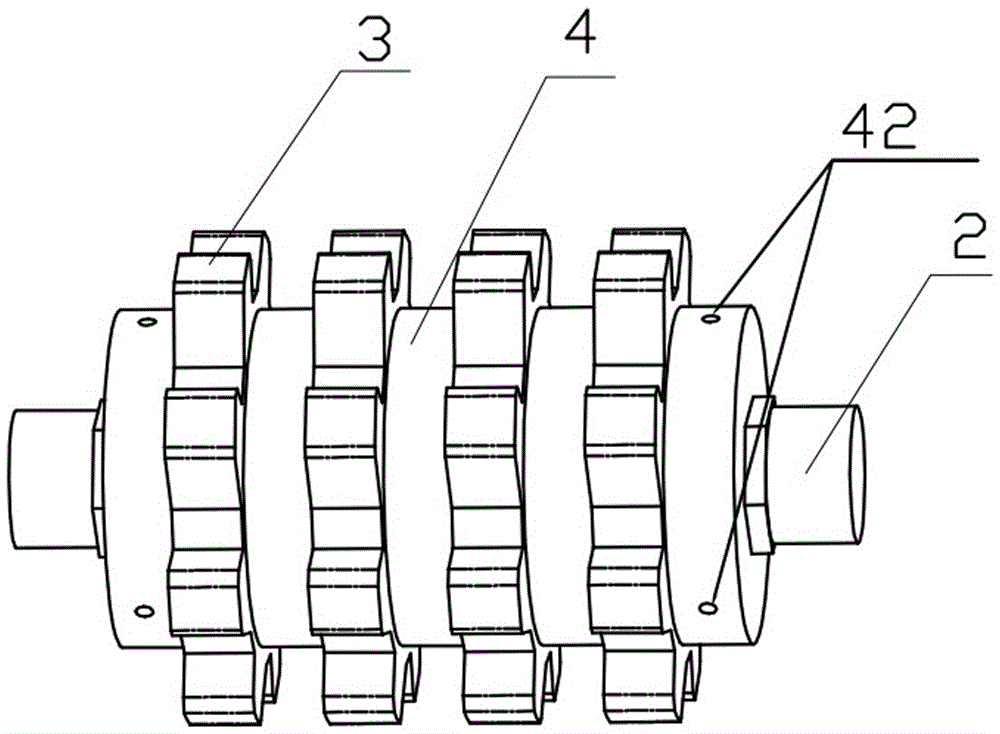

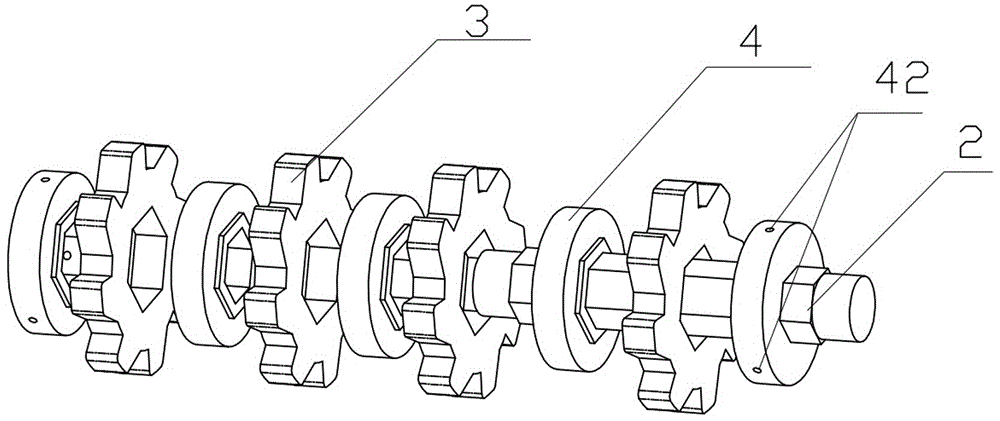

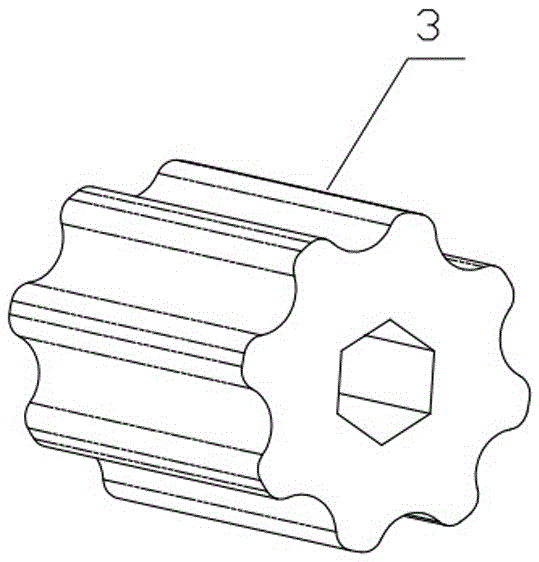

[0025] Aiming at the above-mentioned technical solutions, in order to specifically illustrate, a preferred embodiment is given and illustrated in conjunction with illustrations. flower roller ceramic roller, see Figure 1 to Figure 11 .

[0026] The patterned ceramic roller 1, the block roller shaft 2, the patterned roller 3 and the round roller 4, the patterned roller and the round roller are alternately arranged and combined on the roller shaft to form a patterned ceramic roller. In this embodiment, the roller shaft at the location of the patterned roller and the round roller adopts a hexagonal roller shaft, and the roller shaft can also adopt other structures, such as quadrangular, pentagonal, cylindrical with key grooves, etc. The material of the roller shaft is selected Carbon steel, stainless steel or other permissible metal materials, the two ends of the roller shaft are cylindrical structures for the rotation of the roller shaft. The shape of the hollow part of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com