Chemical experiment fuming cupboard with adjusting air draft and air distribution

A technology of chemical experiments and fume hoods, which is applied in the direction of chemical instruments and methods, dust removal, cleaning methods and utensils, etc. It can solve the problem of corrosion test equipment, turbulent air flow inside the fume hood, and the inability to effectively understand the location of harmful gas pollution sources and fume hoods etc. to achieve the effect of reducing turbulent airflow, avoiding turbulent flow or airflow vortex, and good synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The content of the present invention will be described below in conjunction with specific embodiments.

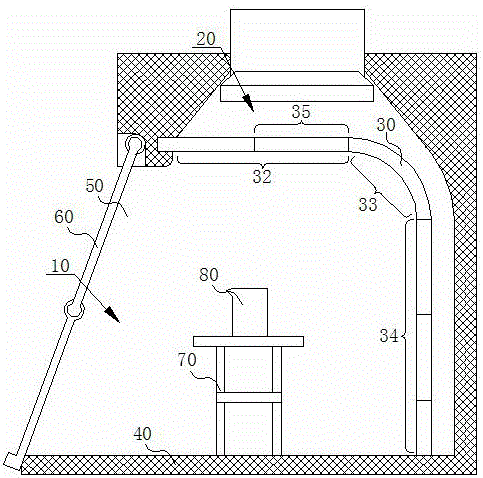

[0023] Such as figure 1 with figure 2 As shown, it is a schematic structural diagram of a chemical experiment fume hood with ventilation and air distribution adjustment described in this embodiment.

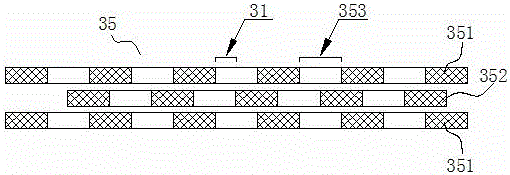

[0024] A chemical experimental fume hood with ventilation and air distribution adjustment described in this embodiment includes an experimental operation part 10 for providing a semi-enclosed space for experimental operation, and an experimental operation part 10 for providing negative pressure to the experimental operation part 10 for air extraction. Negative pressure exhaust part 20; between the experimental operation part 10 and the negative pressure exhaust part 20, an exhaust air distribution adjustment mechanism 30 is arranged, the exhaust air distribution adjustment mechanism 30 is a planar structure, and one side of the exhaust air distribution adjustment mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com