Electrochemical machining system

A technology of electrochemical processing and electrodes, which is applied in the direction of electrochemical processing equipment, electric processing equipment, processing special circuits, etc., can solve problems such as low precision, lagging development, and failure to meet precision processing requirements, and meet high-precision processing requirements and improve The effect of adjusting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

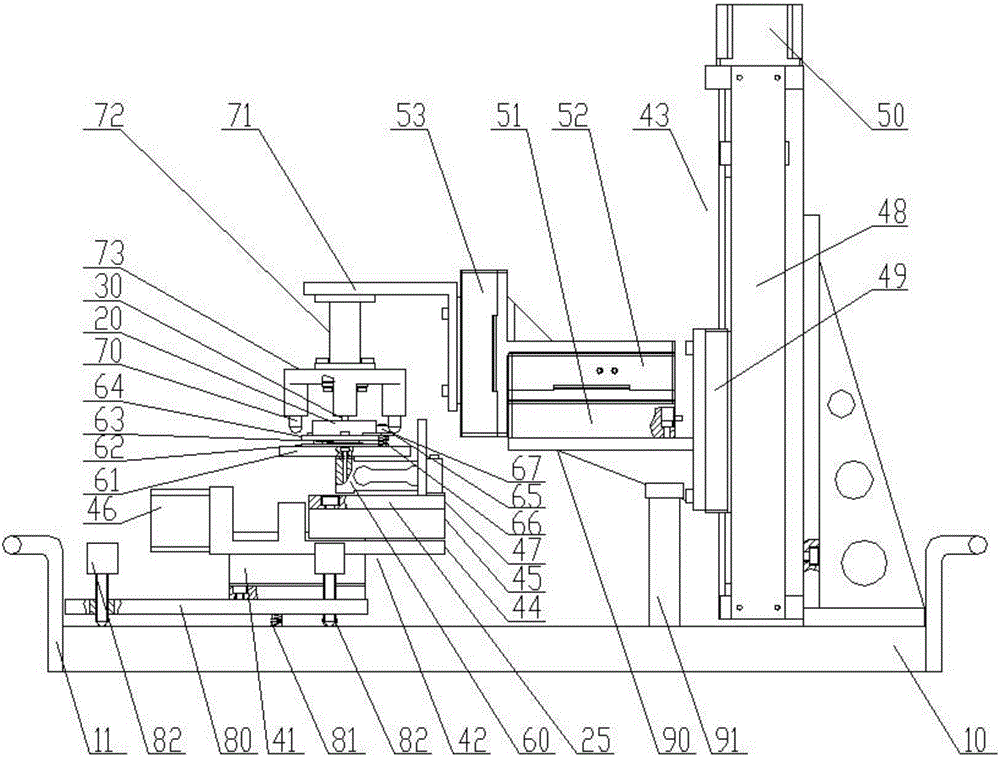

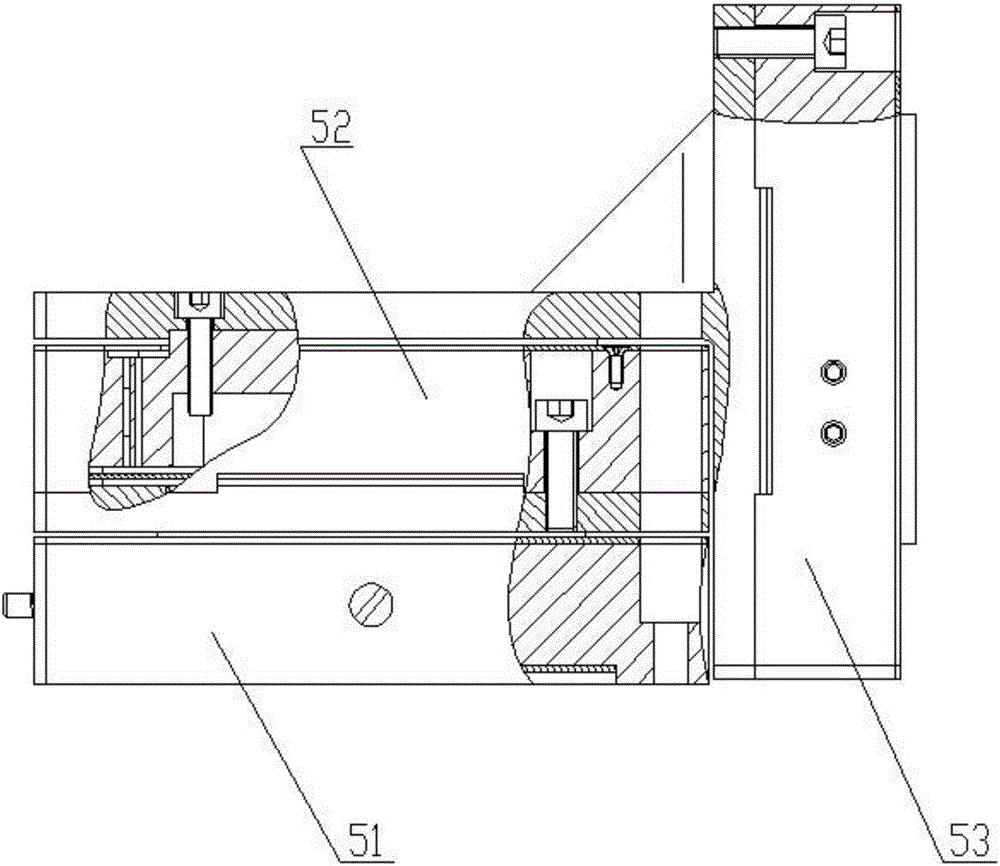

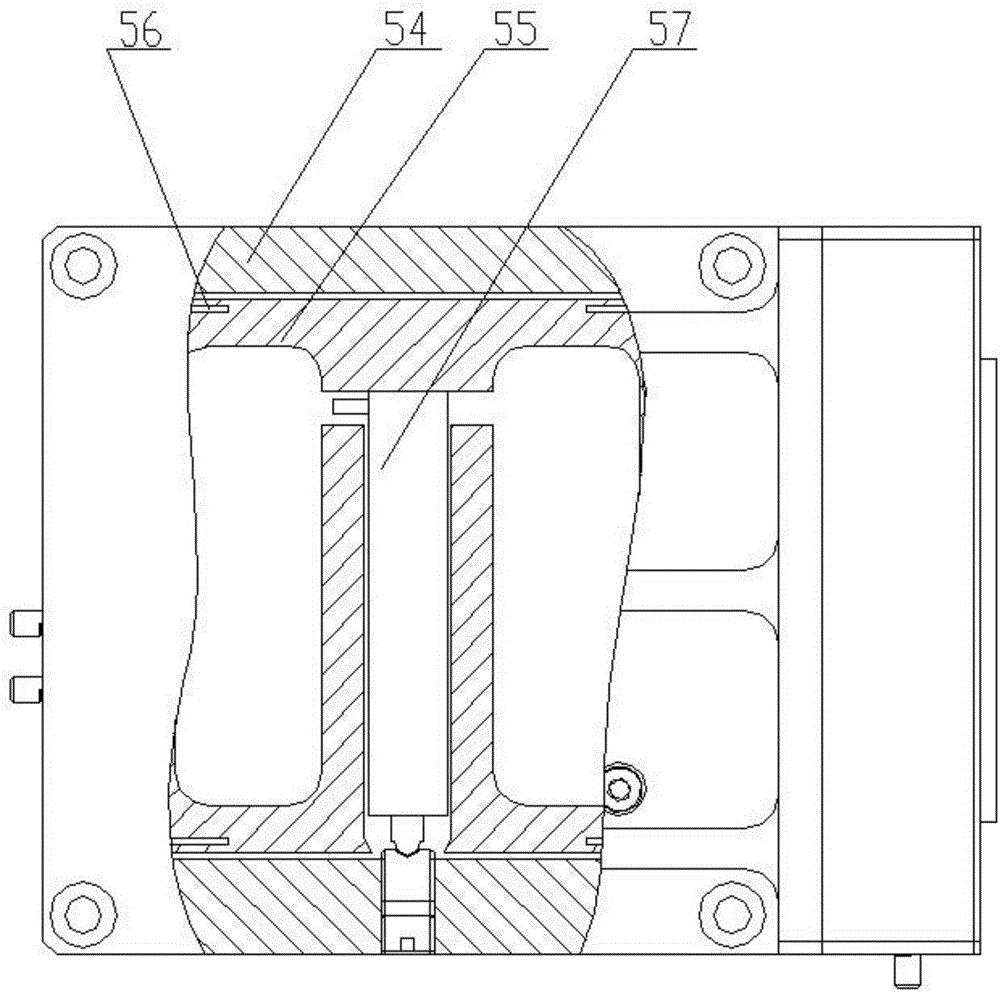

[0042] see figure 1 and figure 2 An electrochemical machining system according to a preferred embodiment of the present invention includes a base 10 , an electrolytic cell 20 and a processing electrode 30 facing the electrolytic cell 20 , and the processing electrode 30 is used to process workpieces in the electrolytic cell 20 . Electrochemical machining is mainly through anodic dissolution or cathodic deposition, so that the workpiece is dissolved or deposited in the electrolyte to achieve the purpose of processing. The electrochemical machining system of the present invention is used for precise machining of workpieces. In order to achieve precision, the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com