welding equipment

A technology for welding equipment and connecting shafts, applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve problems such as poor precision, uneven spot tin, and failure to meet welding requirements, etc., to achieve solder flatness, good welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

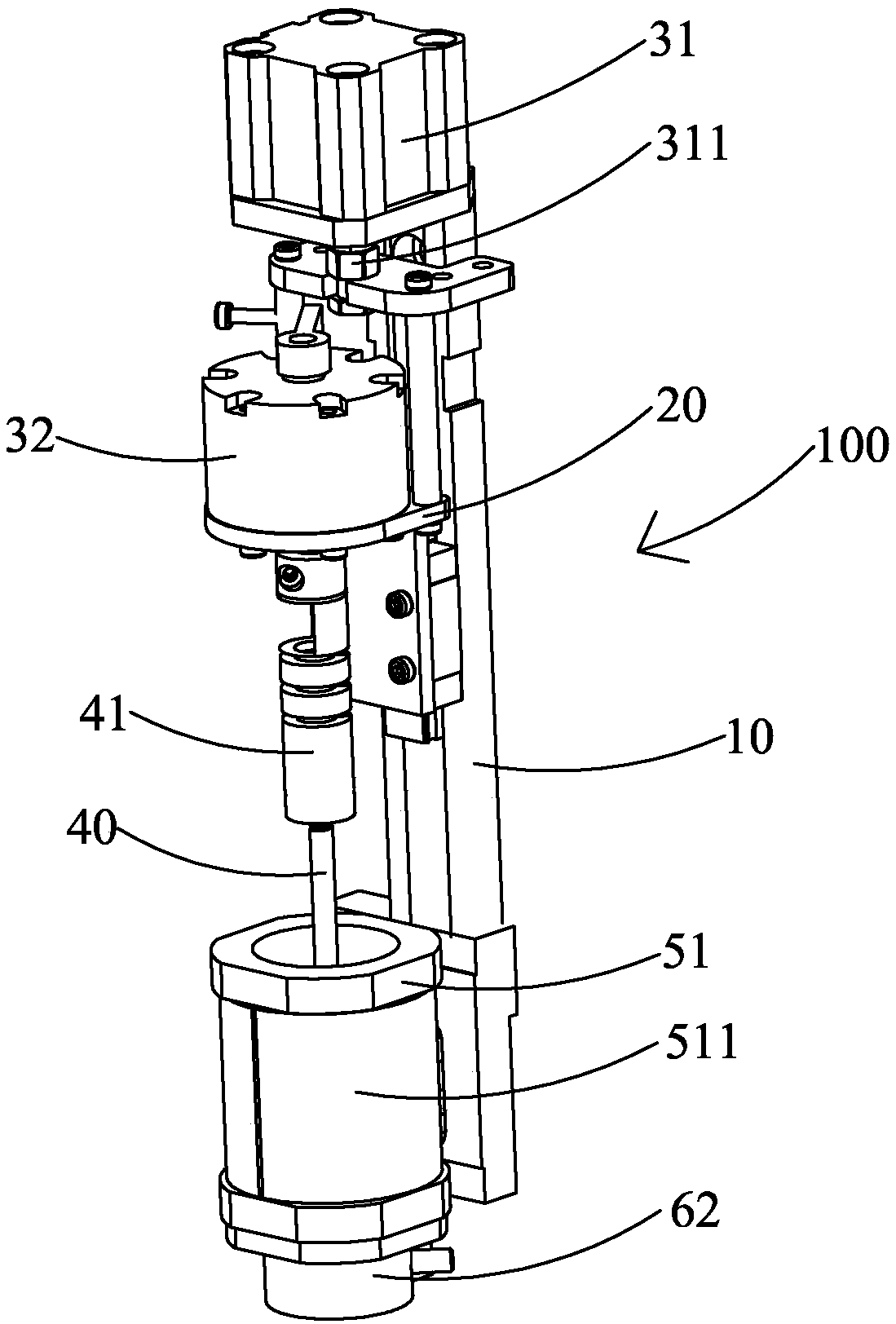

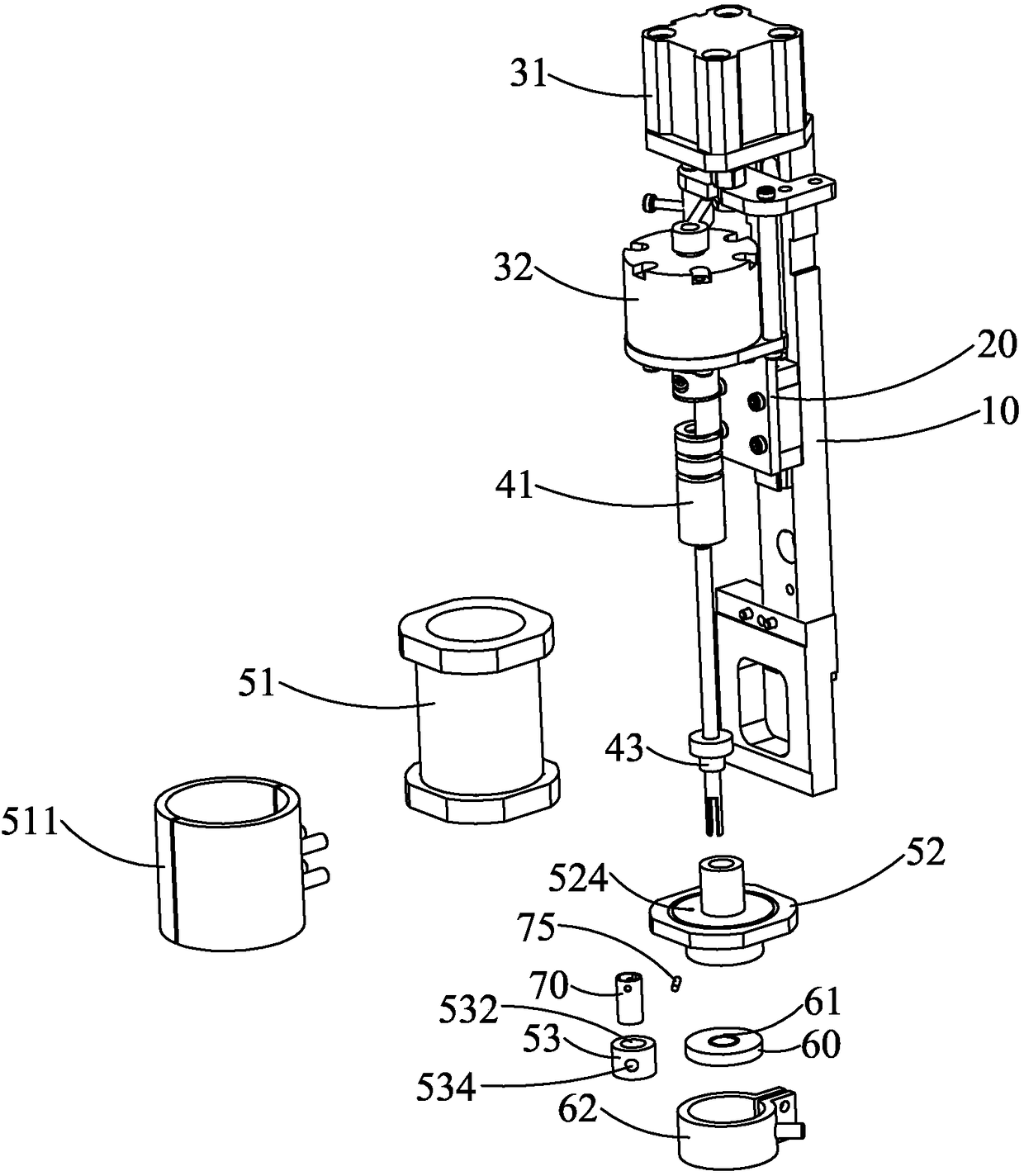

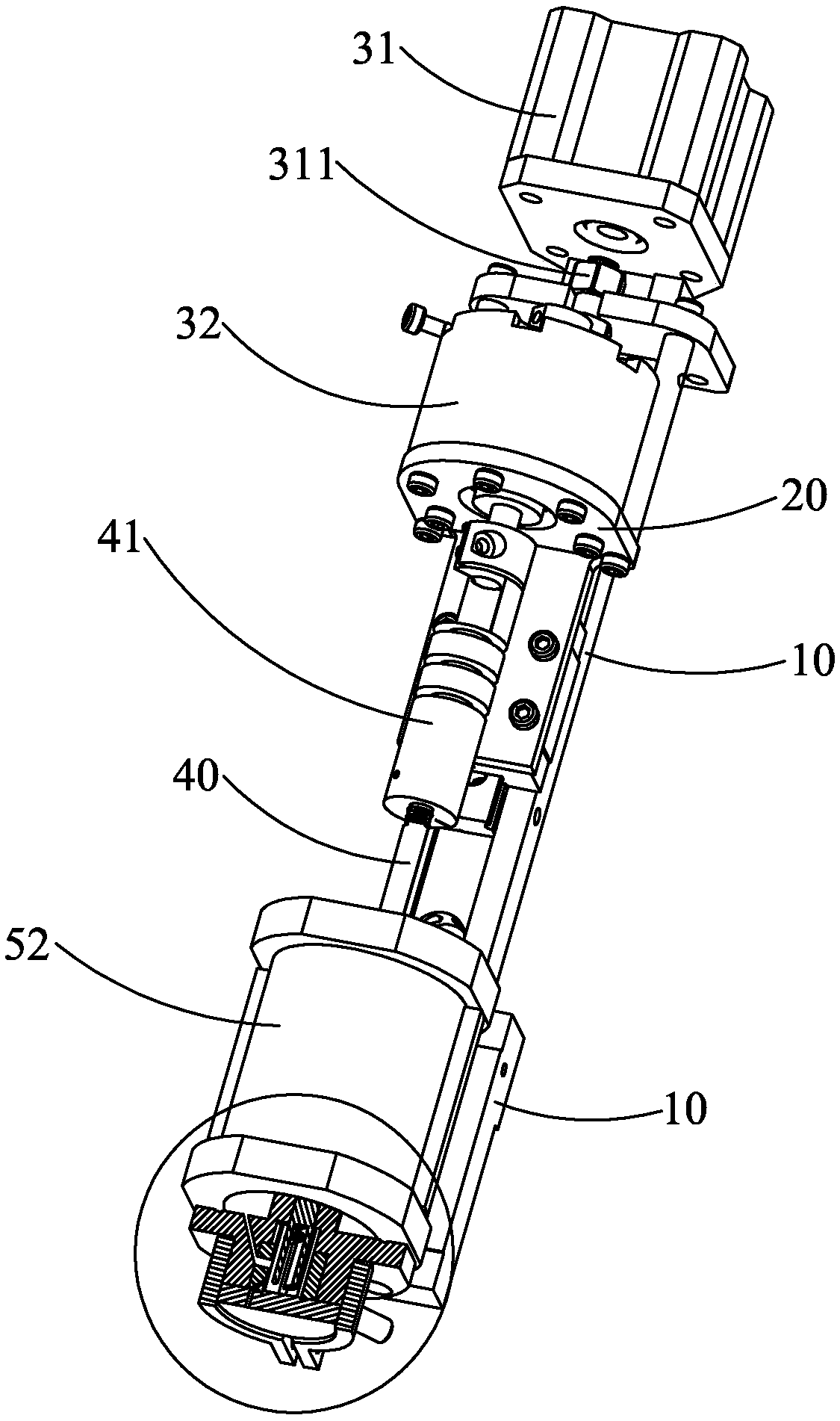

[0023] see Figure 1 to Figure 8 As shown, the welding equipment 100 of the present invention includes a frame 10, a sliding support 20, a displacement cylinder 31, a reversing cylinder 32, a plunger 40, an upper cavity 51, a lower cavity 52, an inner cavity 53, a base plate 60 and a rotating valve 70.

[0024] The frame 10 is set upright, and the sliding bracket 20 is slidably set on the frame 10 along the vertical direction. The displacement cylinder 31 is fixed on the frame 10 and is located above the sliding bracket 20. A displacement coupling shaft 311 is arranged between the two. The displacement cylinder 31 drives the sliding bracket 20 to move up and down through the displacement coupling shaft 311. The reversing cylinder 32 is fixed on the sliding bracket 20 and moves up and down following the sliding bracket 20 .

[0025] The plunger 40 is located below the reversing cylinder 32 , and a reversing coupling shaft 41 is connected between them, and the reversing cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com