Plasma arc-assisted MIG material increase manufacturing method for aluminum alloy structure

A plasma arc and additive manufacturing technology, applied in the field of 3D printing, can solve the problems of large heat input, wide heat-affected zone, and TIG auxiliary arc is not easy to stabilize, so as to improve the forming quality, improve reliability, and achieve high-quality increase. The effect of material manufacturing and forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

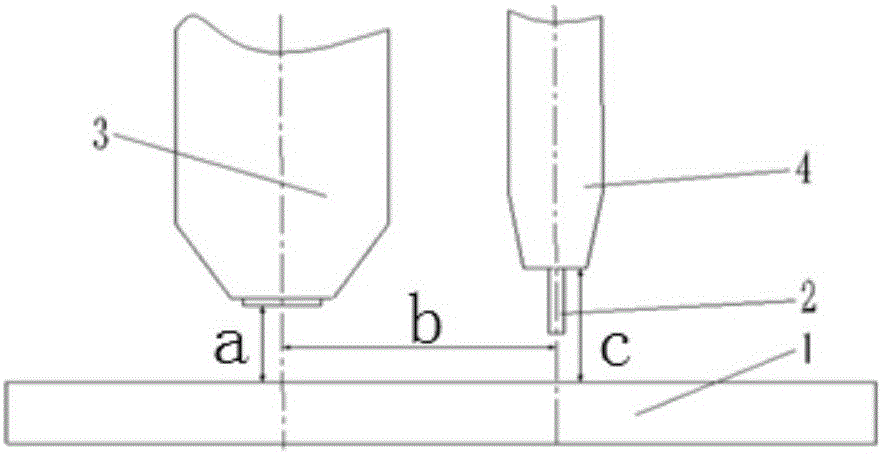

[0019] Example 1: Such as figure 1 As shown, the 6061 aluminum alloy substrate 1 is selected as an example, the diameter of the welding wire 2 is 1.2mm, and the relative positional relationship of the aluminum alloy substrate 1, plasma arc nozzle 3 and MIG welding torch 4 is determined: the distance a between plasma arc nozzle and aluminum alloy substrate is 5mm, plasma The distance b between the arc nozzle and the MIG welding gun 4 is 4 mm, the distance between the aluminum alloy substrate and the MIG welding gun 4 is 12 mm; the current of the MIG welding gun 4 is 120 A; the current ratio of the plasma arc to the MIG welding gun 4 is 0.8. During forming, the plasma arc is in front and the MIG welding torch is behind. The plasma arc preheats the aluminum alloy while remelting the aluminum alloy to improve the flatness of the formed surface, and at the same time, it can effectively remove the oxide film and reduce the range of the heat affected zone. The oxide film on the surfac...

Embodiment 2

[0020] Example 2: This example is different from Example 1: In this example, the 6061 aluminum alloy substrate 1 is selected as an example, the diameter of the welding wire 2 is 1.6mm, and the relative positions of the aluminum alloy substrate 1, plasma arc nozzle 3 and MIG welding gun 4 are determined Relationship: the distance a between the plasma arc nozzle 3 and the aluminum alloy substrate 1 is 6mm, the distance b between the plasma arc nozzle 3 and the MIG welding torch 4 is 8mm, and the distance c between the aluminum alloy substrate 1 and the MIG welding torch 4 is 10mm; the current of the MIG welding torch 4 is 160A; plasma The current ratio of arc to MIG welding gun is 0.6.

Embodiment 3

[0021] Example 3: This example is different from Example 1: In this example, the 6061 aluminum alloy substrate 1 is selected as an example, the diameter of the welding wire 2 is 1.4mm, and the relative positions of the aluminum alloy substrate 1, plasma arc nozzle 3 and MIG welding gun 4 are determined Relationship: The distance a between the plasma arc nozzle 3 and the aluminum alloy substrate 1 is 10mm, the distance b between the plasma arc nozzle 3 and the MIG welding torch 4 is 10mm, and the distance c between the aluminum alloy substrate 1 and the MIG welding torch 4 is 15mm; the current of the MIG welding torch 4 is 100A; plasma The current ratio of the arc to the MIG welding gun is 0.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com