Dismounting device for internal rubber mixer rotor bearing

A closed rubber mixing machine and dismantling device technology, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problems of time-consuming and labor-intensive bearing surface, damage, and inability to eject the bearing, so as to avoid bearing damage, smooth movement, and stress uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

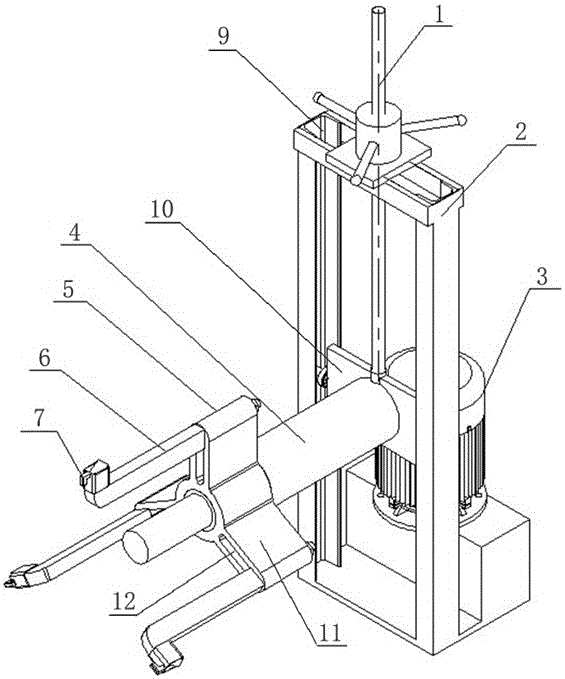

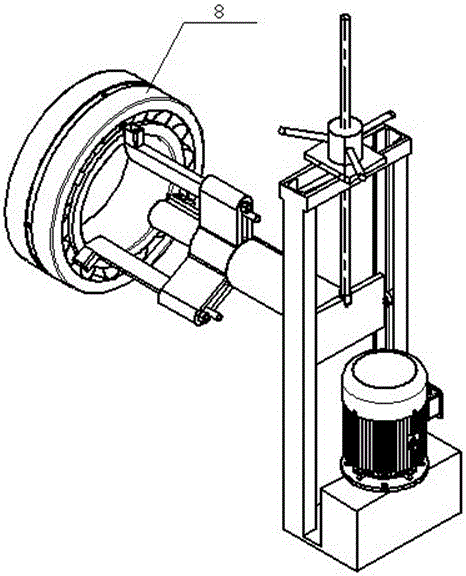

[0021] figure 1 It is a structural schematic diagram of the dismantling device for the rotor bearing of the closed rubber mixing machine of the present invention. Such as figure 1 As shown, the dismantling device for the rotor bearing of the closed rubber mixing machine of the present invention includes a lifting screw 1, a frame 2, a hydraulic pump 3, an oil cylinder 4, a claw seat 5, a claw 6 and a hook 7.

[0022] It specifically includes: a frame 2, the frame 2 is provided with a chute 9; a lifting screw 1 is installed on the frame 2; an oil cylinder 4 is fixedly connected with the bottom of the lifting screw 1 through a slide plate 10, and the slide plate 10 Slidingly connected to the chute 9; hydraulic pump 3, used to drive the action of the oil cylinder 4; jaw base 11, set on the front end of the oil cylinder 4; jaw base 5, the jaw base is three , three claw seats are evenly distributed on the outer surface of the seat, and a hollow groove body 12 is arranged inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com