Heating bag cloth forming and cutting integrated production line

A bag cloth and production line technology, applied in the field of heating bag cloth processing equipment, can solve the problems of manpower consumption, low work efficiency, unfavorable mass production of products, etc., and achieve simple structure, fast processing efficiency, stability and quality Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

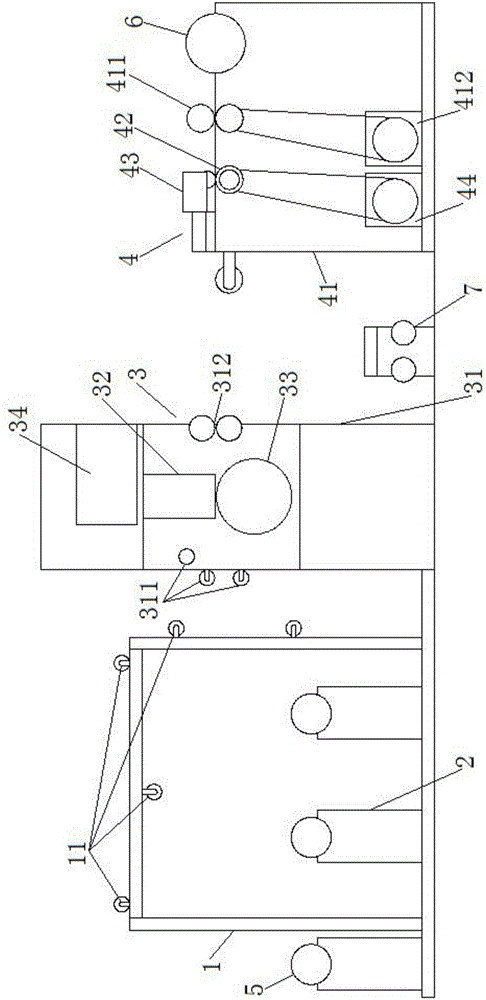

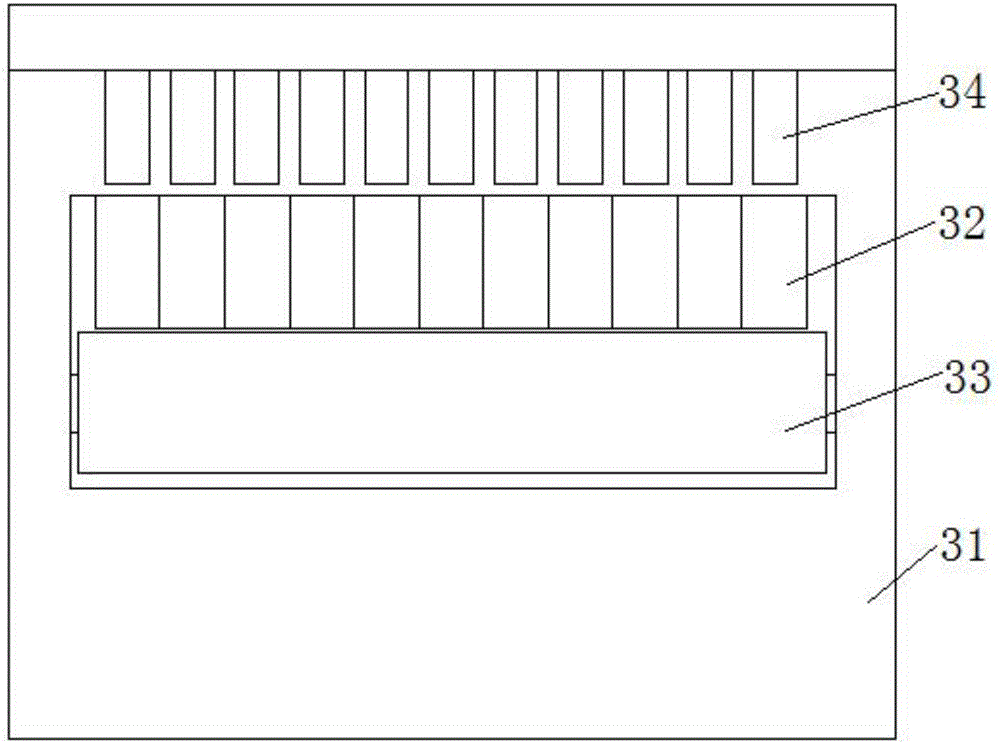

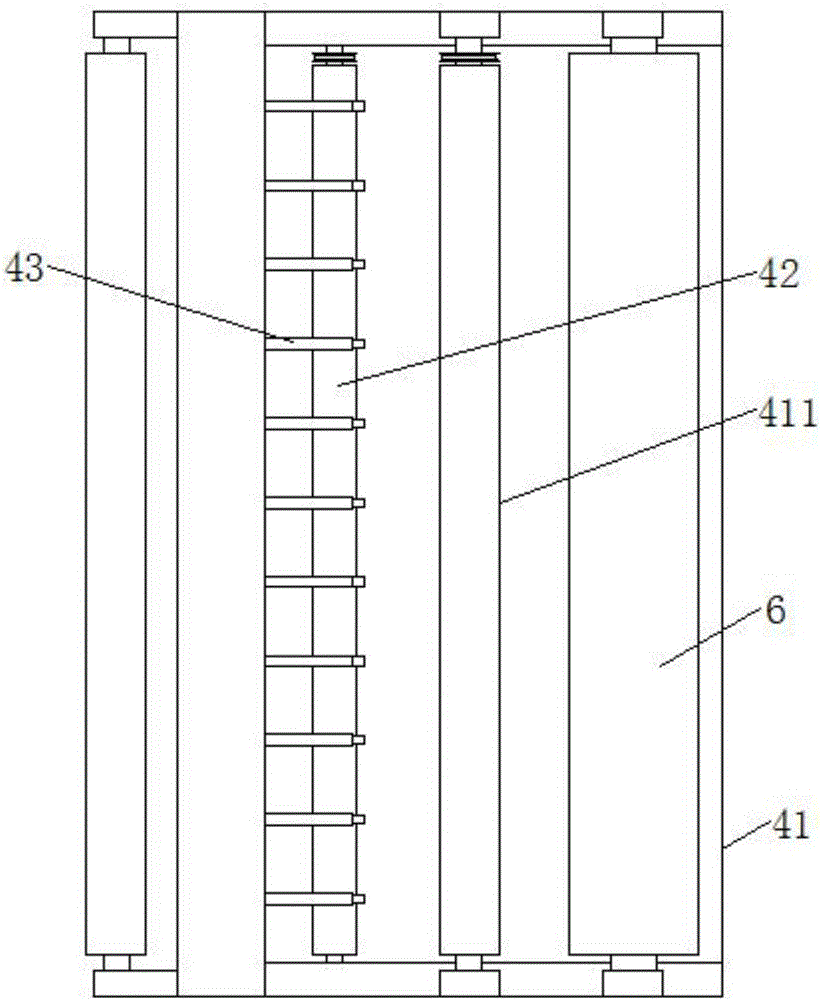

[0031] Example: such as figure 1 As shown, the heating bag cloth forming and cutting integrated production line of this embodiment includes a frame 1, a number of roller support seats 2, an ultrasonic bonding punching system 3 and a cutting system 4. The above frame 1 is installed on the above ultrasonic On one side of the adhesive punching system 3, the above-mentioned cutting system 4 is arranged on the other side of the above-mentioned ultrasonic bonding punching system 3, and several of the above-mentioned roller support seats 2 are arranged in parallel and fixed in the above-mentioned frame 1 at intervals, and each of the above-mentioned The detachable rotation on the roller supporting base 2 is installed with a piece material cylinder 5, and the corresponding winding on the above-mentioned piece material cylinder 5 is to be processed.

[0032] Preferably, there are three roller support seats 2 mentioned above.

[0033] During the production process, the three kinds of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com