Retortable cast film and production method thereof

A production method and casting film technology, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of wasting materials, not being environmentally friendly, and low production efficiency, so as to reduce processing procedures and avoid Waste of resources and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for producing retort-resistant cast film, the steps of the production method are:

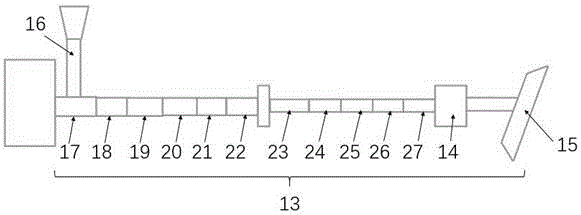

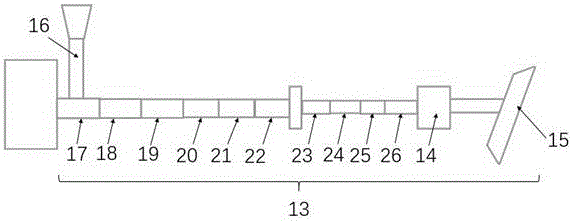

[0045](1) Preparation and weighing of raw materials: Prepare raw material particles according to the composition of the eleven-layer structure of the cast film, and send the raw material particles into the corresponding feeding hopper 12 through a suction device and a weighing device;

[0046] (2) Extruder 13 shear heating: ten extruders 13 respectively shear and heat the raw material particles in the hopper 12 to obtain raw materials in a molten state, and transport them to the aggregate block 14 through the interface;

[0047] (3) Aggregate block 14: The aggregate block 14 is provided with four heating zones, the temperatures are: 240°C, 240°C, 240°C, 240°C; After the raw materials are processed, they enter the aggregate block 14, and the aggregate block 14 distributes the raw materials extruded by the extruder 13 to form an eleven-layer product structure required by the proce...

Embodiment 2

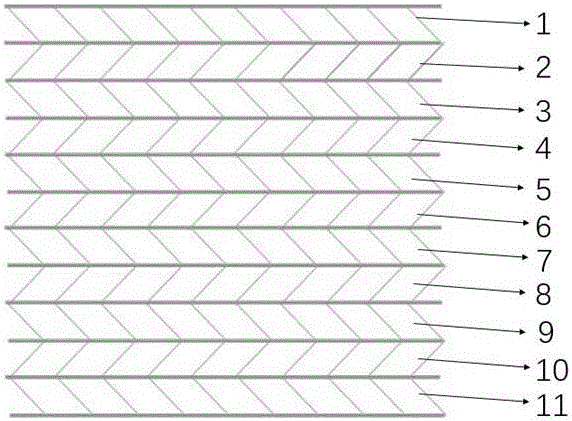

[0068] The casting film prepared by the preparation method of Example 1 has a total of eleven layers, and from top to bottom are the first PA layer 1, the second adhesive layer 2, the third PP layer 3, and the fourth PP layer 4 , the fifth PP layer 5, the sixth PP layer 6, the seventh PP layer 7, the eighth PP layer 8, the ninth PP layer 9, the tenth PP layer 10 and the eleventh PP layer 11;

[0069] The thickness of the first PA layer 1 is 15 μm, the thickness of the second adhesive layer 2 is 5 μm, the thickness of the third PP layer 3 is 6 μm, the thickness of the fourth PP layer 4 is 5 μm, and the thickness of the fifth PP layer 5 is 6 μm , the thickness of the sixth PP layer 6 is 5 μm, the thickness of the seventh PP layer 7 is 5 μm, the thickness of the eighth PP layer 8 is 5 μm, the thickness of the ninth PP layer 9 is 11 μm, and the thickness of the tenth PP layer 10 is 11 μm , the thickness of the eleventh PP layer 11 is 7 μm.

[0070] The first PA layer 1 is a reinf...

Embodiment 3

[0072] The casting film prepared by the preparation method of Example 1 has a total of eleven layers, and from top to bottom are the first PA layer 1, the second adhesive layer 2, the third PP layer 3, and the fourth PP layer 4 , the fifth PP layer 5, the sixth PP layer 6, the seventh PP layer 7, the eighth PP layer 8, the ninth PP layer 9, the tenth PP layer 10 and the eleventh PP layer 11;

[0073] The thickness of the first PA layer 1 is 15 μm, the thickness of the second adhesive layer 2 is 10 μm, the thickness of the third PP layer 3 is 11 μm, the thickness of the fourth PP layer 4 is 12 μm, and the thickness of the fifth PP layer 5 is 12 μm , the thickness of the sixth PP layer 6 is 12 μm, the thickness of the seventh PP layer 7 is 12 μm, the thickness of the eighth PP layer 8 is 12 μm, the thickness of the ninth PP layer 9 is 20 μm, and the thickness of the tenth PP layer 10 is 20 μm , the thickness of the eleventh PP layer 11 is 14 μm.

[0074] Other parts are complet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com