Resin mortar applied for FRPM pipes and a preparing method thereof

A technology of resin mortar and resin, applied in the field of high-performance resin mortar and its production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

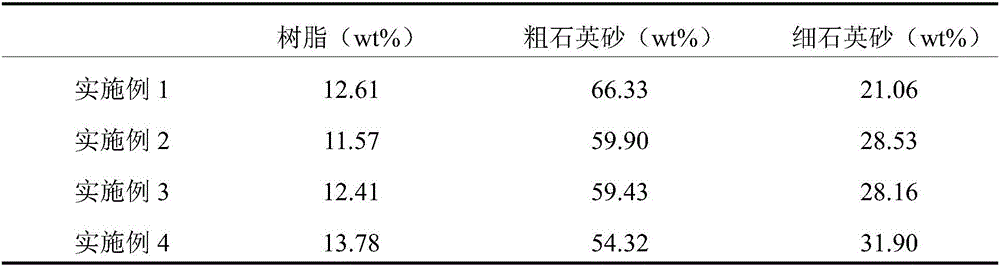

Examples

Embodiment 3

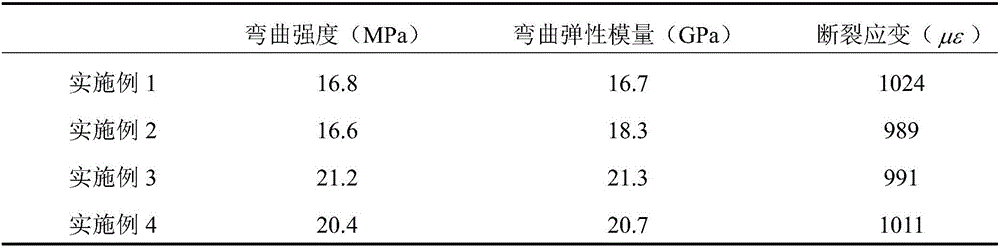

[0044] Taking Example 3 and testing it in an environment of 25°C, the measured average flexural modulus of elasticity is 17.5GPa.

[0045] Each embodiment resin mortar density of table 4

[0046]

[0047]

[0048] From the comparison results, it can be seen that the influence of different quartz sand grades on the finished resin mortar has the following two aspects:

[0049] (1) Resin dosage

[0050] As a multi-component aggregate grading system, the bulk density of the mixed graded quartz sand is closely related to the porosity, and the porosity between the particles of the graded quartz sand with high bulk density is smaller, and the amount of resin cement used for filling is also less. , and then the amount of resin has also been reduced.

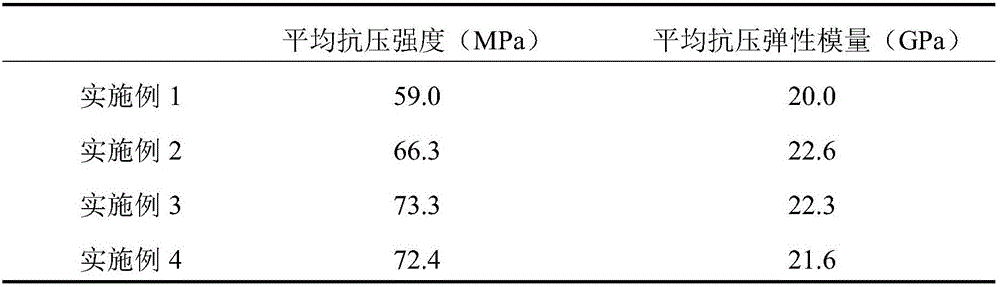

[0051] (2) Mechanical properties

[0052] The resin mortar with high density is denser inside and has fewer defects, so its mechanical properties are better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com