Method for preparing frame-type raft frame or base from composite material

A composite material and frame-type technology, applied in adhesive types, epoxy resin glue, shipbuilding, etc., can solve the problems of high strength, high rigidity, and high precision, and achieve high strength, high specific stiffness, and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the content of the present invention more obvious and understandable, the present invention will be described in detail below in conjunction with specific embodiments.

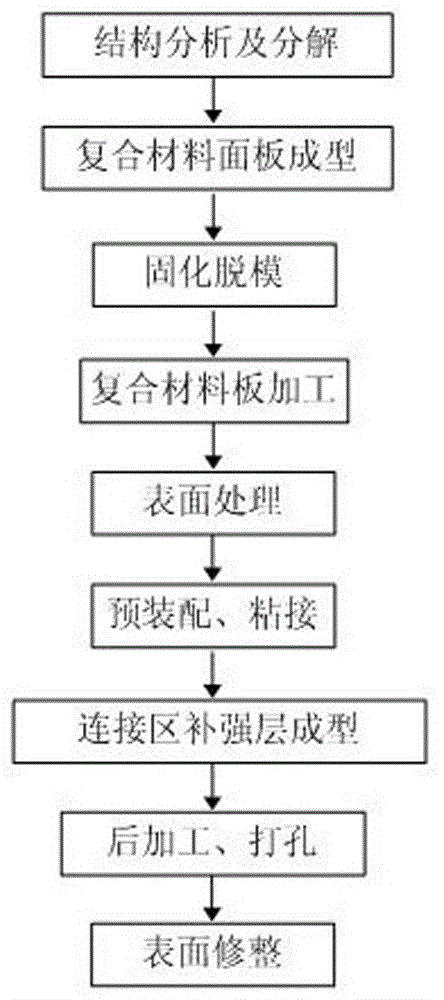

[0044] A method for preparing a frame-type raft or a base using composite materials includes the following steps:

[0045] Step 1: Structural decomposition of raft frame or base

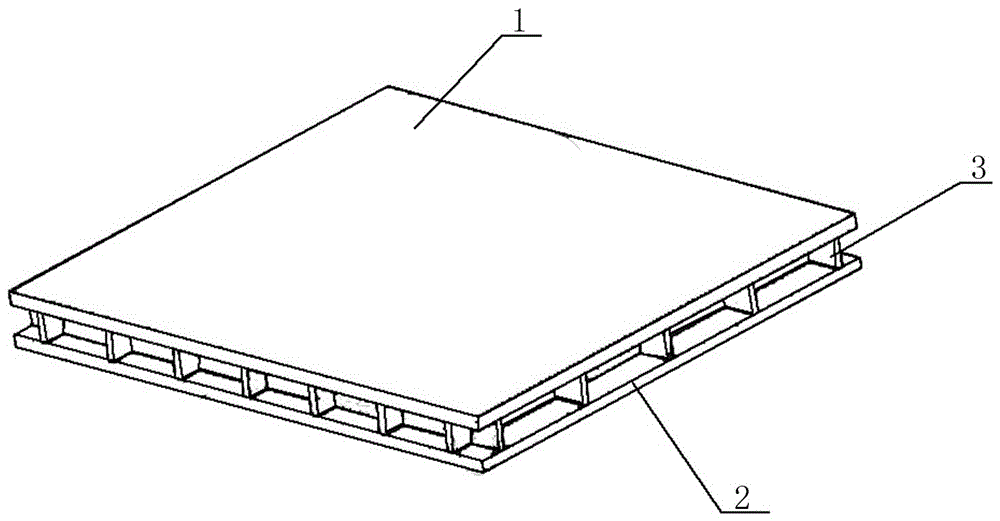

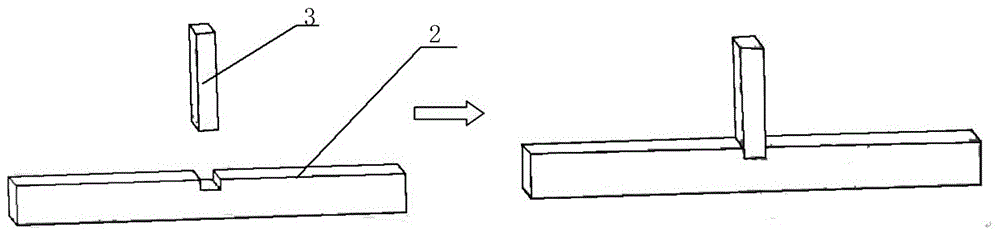

[0046] According to the overall structure of the raft or the base, the structure is decomposed into four parts: the upper panel, the lower panel and the transverse and longitudinal ribs. Among them, the transverse and longitudinal ribs include multiple transverse ribs and longitudinal ribs. The connection between the longitudinal ribs and the lower panel and the transverse and longitudinal ribs are all "T"-shaped splicing, and the connection between the transverse ribs and the longitudinal ribs is the "ten"-shaped splicing, which is finally decomposed Plan, the decomposition plan includes the number and size of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com