Accurate efficient enzyme deactivation device

A high-efficiency, enzyme-killing technology, applied in enzymology/microbiology devices, biochemical cleaning devices, enzyme production/bioreactors, etc. The effect of processing, small footprint and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

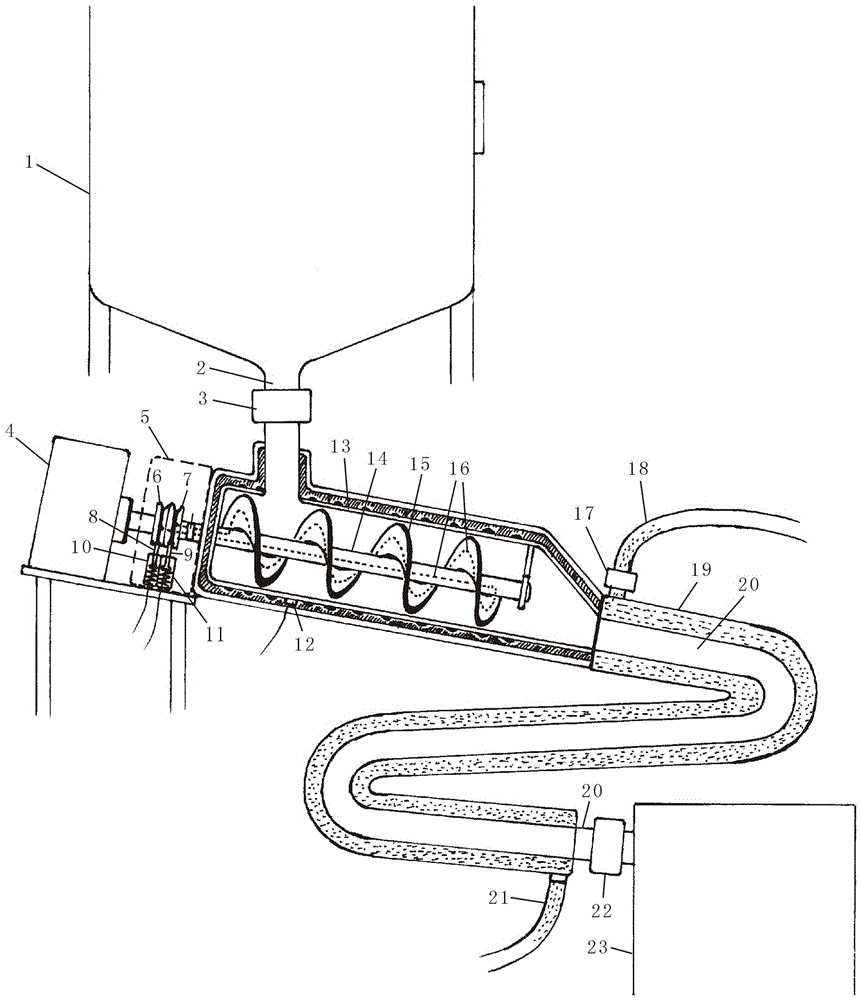

[0011] The present invention is further described now in conjunction with accompanying drawing.

[0012] Such as figure 1 As shown in the figure, 1. Enzymolysis tank, 2. Outlet pipe, 3. The first solenoid valve, 4. Motor, 5. Safety box, 6. The first sheave, 7. The second sheave, 8. The first sheave One conductive rod, 9. the second conductive rod, 10. the first insulating tube, 11. the second insulating tube, 12.

[0013] Temperature sensor, 13. heating cylinder, 14. rotating shaft, 15. auger blade, 16. first heating pipe, 17. second solenoid valve, 18. tap water pipe, 19. cooling pipe, 20. feeding pipe, 21 . Outlet pipe, 22. Pump, 23. Storage tank.

[0014] The discharge pipe 2 of the enzymolysis tank 1 arranged on the ground or on the wall is provided with a first electromagnetic valve 3; the discharge pipe 2 is connected with the heating cylinder 13, and the outlet of the heating cylinder 13 is connected The feeding pipe 20 is connected to the feeding pipe 20, which is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com