Cooling device for bearing outer sleeve machining

A bearing jacket and cooling device technology, applied in quenching devices, manufacturing tools, heat treatment equipment, etc., can solve the problems of poor cooling effect, reduced friction coefficient, and large water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

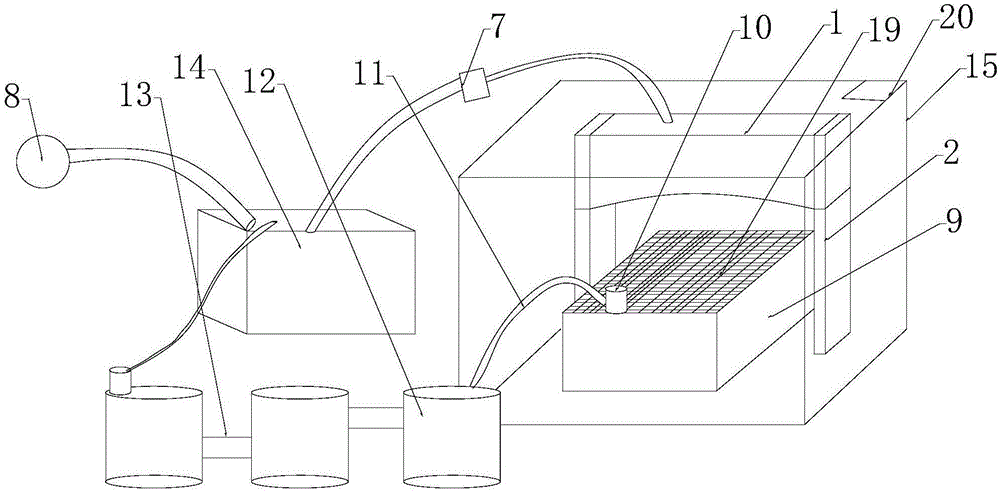

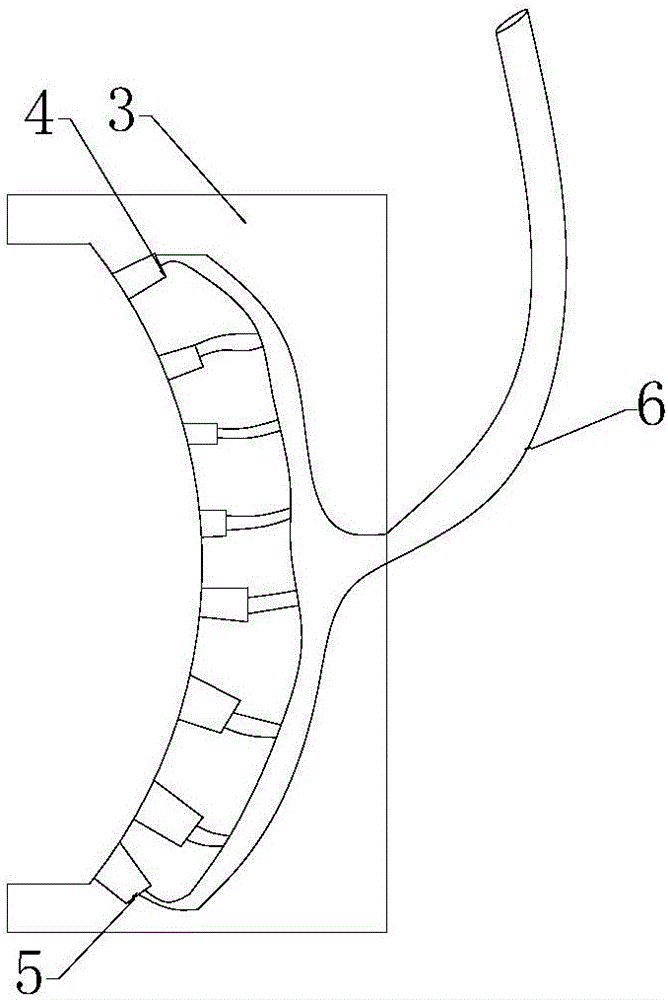

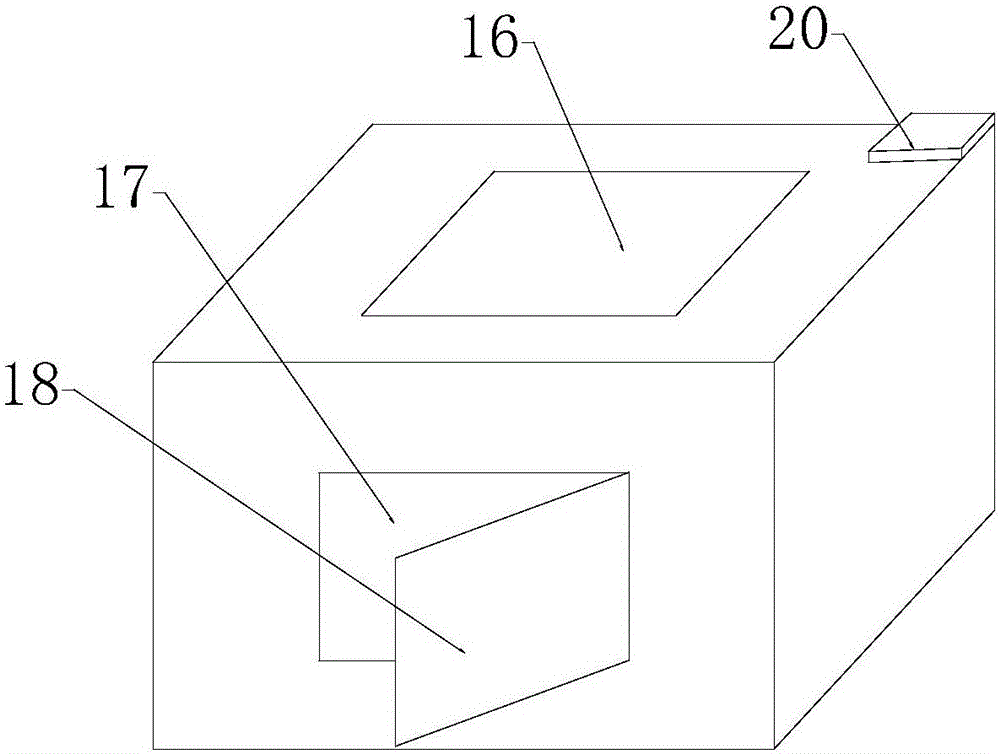

[0018] As shown in the accompanying drawings, a cooling device for bearing outer casing processing includes a water spray unit 1, a water spray device, and a water collection device installed under the water spray unit 1. The water spray unit 1 includes a bracket 2 and is installed on the bracket 2. The installation block 3, the lower end surface of the installation block 3 is provided with an arc surface, the arc surface is provided with several installation holes 4, the bottom surface of the installation block 3 is connected with the support 2, and the water spray device includes nozzles 5 installed in the installation holes 4, through The water delivery pipe 6 passing through the end face of the installation block 3 and connected to the nozzle 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com