Plasma fiber modification technology based oversized jacquard fabric

A technology of fiber modification and plasma, which is applied in the field of textile fabrics, can solve the problems of unsatisfactory fabrics, and achieve the effect of unique style, excellent internal quality and good sense of fashion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

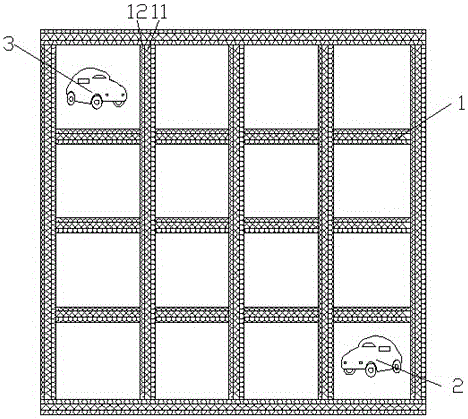

Image

Examples

Embodiment 1

[0023] Super jacquard fabric based on plasma fiber modification technology, after plasma yarn pretreatment process and weaving process, obtain super jacquard fabric based on plasma fiber modification technology, the steps are as follows:

[0024] (1) Plasma yarn pretreatment process: under the condition of 30Pa, 100W, the gas is injected for plasma pretreatment, the treatment time is 5min, and the gas is one or a mixture of air and oxygen;

[0025] (2) Weaving process: the treated warp and weft yarns are arranged and combined according to the specific warp and weft yarns for plain weave weaving to form super jacquard fabrics.

Embodiment 2

[0027] Super jacquard fabric based on plasma fiber modification technology, after plasma yarn pretreatment process and weaving process, obtain super jacquard fabric based on plasma fiber modification technology, the steps are as follows:

[0028] (1) Plasma yarn pretreatment process: under the condition of 55Pa, 160W, the gas is injected for plasma pretreatment, the treatment time is 15min, and the gas is one or a mixture of air and oxygen;

[0029] (2) Weaving process: the treated warp and weft yarns are arranged and combined according to the specific warp and weft yarns for plain weave weaving to form super jacquard fabrics.

Embodiment 3

[0031] Super jacquard fabric based on plasma fiber modification technology, after plasma yarn pretreatment process and weaving process, obtain super jacquard fabric based on plasma fiber modification technology, the steps are as follows:

[0032] (1) Plasma yarn pretreatment process: under the condition of 47Pa, 130W, the gas is injected for plasma pretreatment, the treatment time is 10min, and the gas is one or a mixture of air and oxygen;

[0033] (2) Weaving process: the treated warp and weft yarns are arranged and combined according to the specific warp and weft yarns for plain weave weaving to form super jacquard fabrics.

[0034] Obtain following experimental data by above-mentioned embodiment:

[0035]

Water absorption (%)

Wicking height (mm)

Example 1

200

110

Example 2

200

100

Example 3

240

130

[0036] As can be seen from the above table, the plasma yarn pretreatment process of the above three embodiments c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com