Method for modifying protection material through shear thickening fluid impregnation

A technology of fluid impregnation and protective material, applied in textile and papermaking, fiber processing, fiber type, etc., can solve the problems of lightness and comfort of protective materials and difficult coordination of protective performance, and achieve high strength, good flexibility, and improved strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

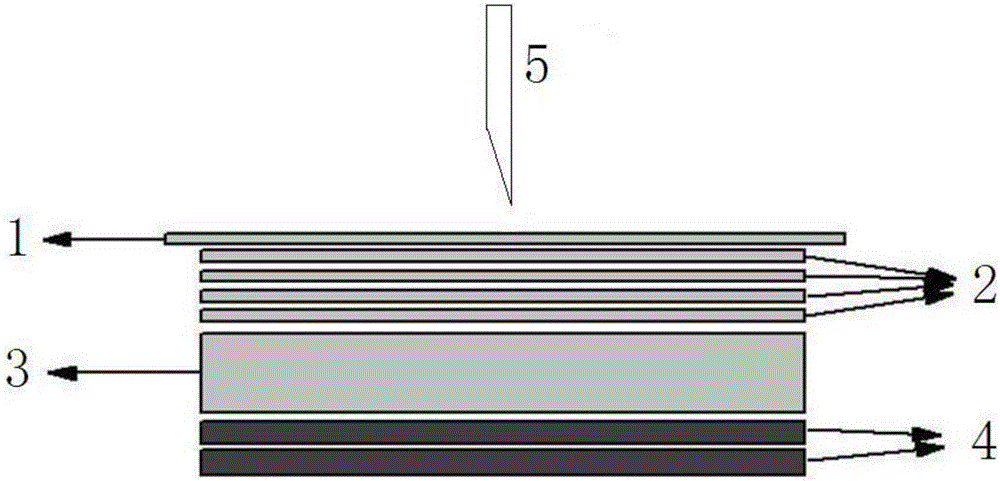

Image

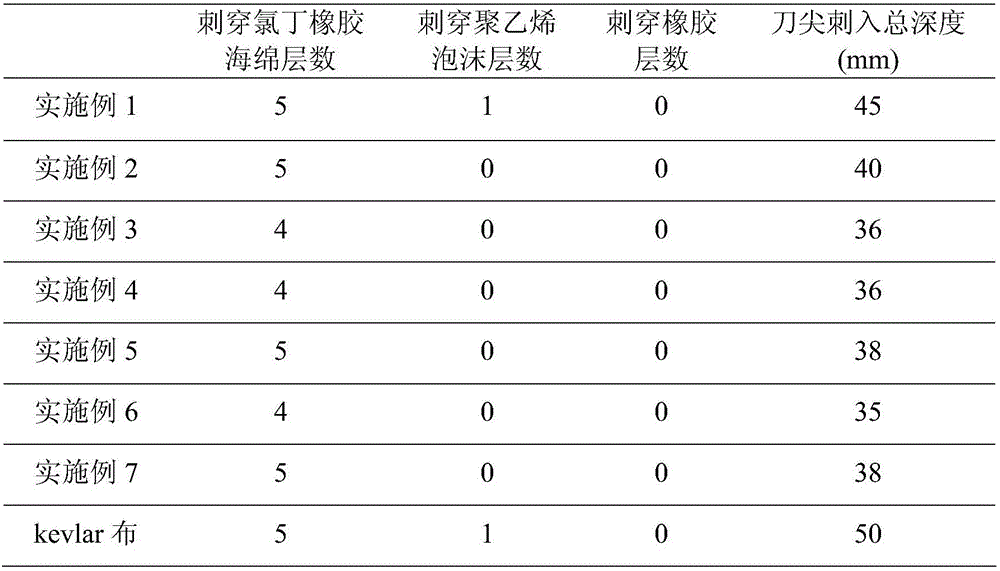

Examples

Embodiment 1

[0023] A method for modifying a protective material by impregnating a shear thickening fluid, comprising the following steps:

[0024] (1) Mix polyethylene glycol and ethanol evenly, then add SiO in batches 2 powder, to prepare a suspension; the SiO 2 , polyethylene glycol, ethanol ratio is volume ratio 10.5:19.5:70; SiO 2 The particle size is 40nm; the average molecular weight of polyethylene glycol is 780-840;

[0025] (2) Centrifuge the suspension, wash the precipitate three times with ethanol, and dry it in vacuum at 80°C for 8 hours to obtain a powder;

[0026] (3) With the dried powder, polyethylene glycol is used as a dispersion medium to configure a suspension with a volume concentration of 8%; (4) the suspension configured in step (3) is diluted with ethanol, and the suspension configured in step (3) The volume ratio of liquid to ethanol is 1:1, and it is shaken with an ultrasonic cleaning machine to make it evenly dispersed, and then the Kevlar cloth is soaked for...

Embodiment 2

[0028] A method for modifying a protective material by impregnating a shear thickening fluid, comprising the following steps:

[0029] (1) Mix polyethylene glycol and ethanol evenly, then add SiO in batches 2 powder, to prepare a suspension; the SiO 2 , polyethylene glycol, and ethanol in a volume ratio of 5:15:60; SiO 2 The particle size is 40nm; the average molecular weight of polyethylene glycol is 780-840;

[0030] (2) Centrifuge the suspension, wash the precipitate three times with ethanol, and dry it in vacuum at 70°C for 10 hours to obtain a powder;

[0031] (3) With the dried powder, polyethylene glycol is used as a dispersion medium to configure a suspension with a volume concentration of 8%;

[0032] (4) Dilute the suspension prepared in step (3) with ethanol, the volume ratio of the suspension prepared in step (3) to ethanol is 1:1, and vibrate with an ultrasonic cleaner to make it evenly dispersed, and then place the Kevlar After soaking for 1 hour, the ultraso...

Embodiment 3

[0034] A method for modifying a protective material by impregnating a shear thickening fluid, comprising the following steps:

[0035] (1) Mix polyethylene glycol and ethanol evenly, then add SiO2 powder in batches to prepare a suspension; the proportioning ratio of SiO2, polyethylene glycol and ethanol is 15:20:70 by volume; the particle size of SiO2 The diameter is 40nm; the average molecular weight of polyethylene glycol is 780-840;

[0036] (2) Centrifuge the suspension, wash the precipitate three times with ethanol, and dry it in vacuum at 90°C for 6 hours to obtain a powder;

[0037] (3) With the dried powder, polyethylene glycol is used as a dispersion medium to configure a suspension with a volume concentration of 8%;

[0038] (4) Dilute the suspension prepared in step (3) with ethanol, the volume ratio of the suspension prepared in step (3) to ethanol is 1:1, and vibrate with an ultrasonic cleaner to make it evenly dispersed, and then place the Kevlar After soaking ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com