PLC-based paper pulp water absorption control system

A control system, pulp water absorption technology, applied in general control system, control/regulation system, program control, etc., can solve the problems of unfavorable energy saving and emission reduction, high motor power, high energy consumption, etc., and achieve favorable transformation and upgrading, high performance Reliable, highly controlled results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

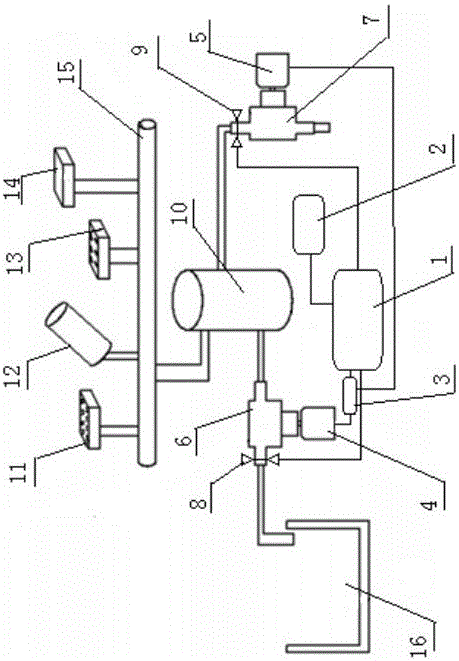

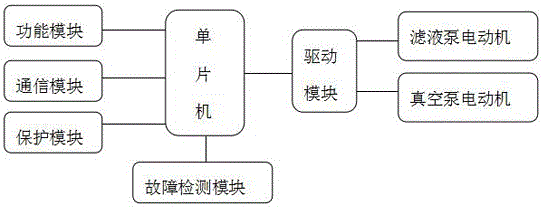

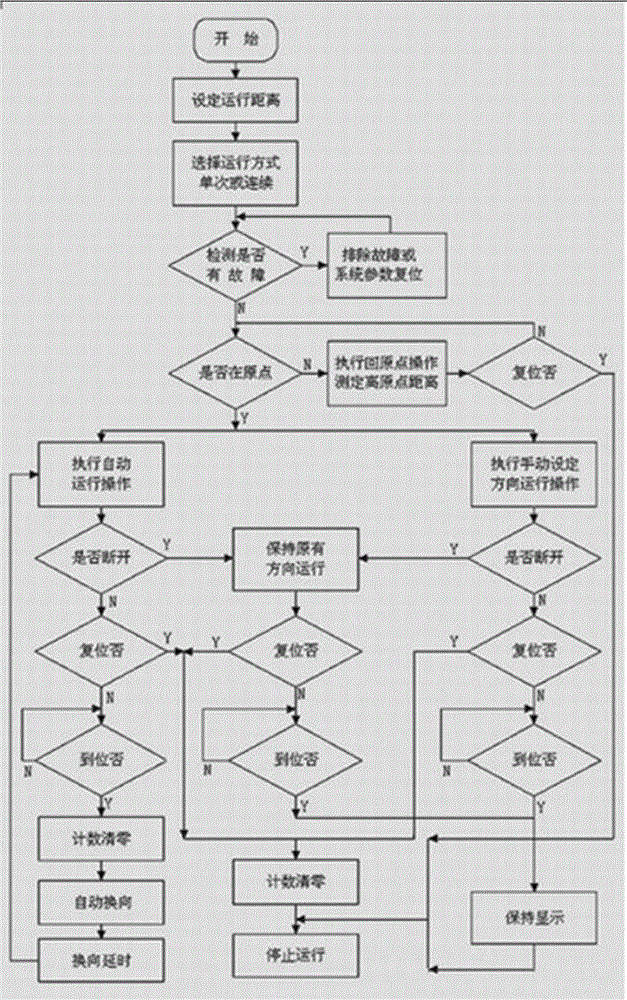

[0062] like figure 1 As shown, a pulp water absorption control system based on PLC, including PLC controller, LCD touch screen, motor driver, vacuum pump, filtrate pump, white water pool, vacuum pump motor, filtrate pump motor, vacuum suction box of wire part, vacuum couch roll, upper Felt vacuum suction box, lower felt vacuum suction box, main pipe and front air-water separator;

[0063] The vacuum suction box, vacuum couch roll, upper felt vacuum suction box and lower felt vacuum suction box are connected by a main pipe, the main pipe is connected with the front air-water separator, the front air-water separator is connected with the vacuum pump, the front air-water The separator is also connected to the white w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com