Electric heating element support structure and automobile exhaust gas purification device using the structure

A technology of electric heating elements and supporting structures, which is applied in the direction of exhaust devices, noise reduction devices, engine components, etc., can solve the problem that the outer diameter of the metal capillary should not be too large, so as to improve the catalytic conversion efficiency, prevent contact short circuit, and prevent deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

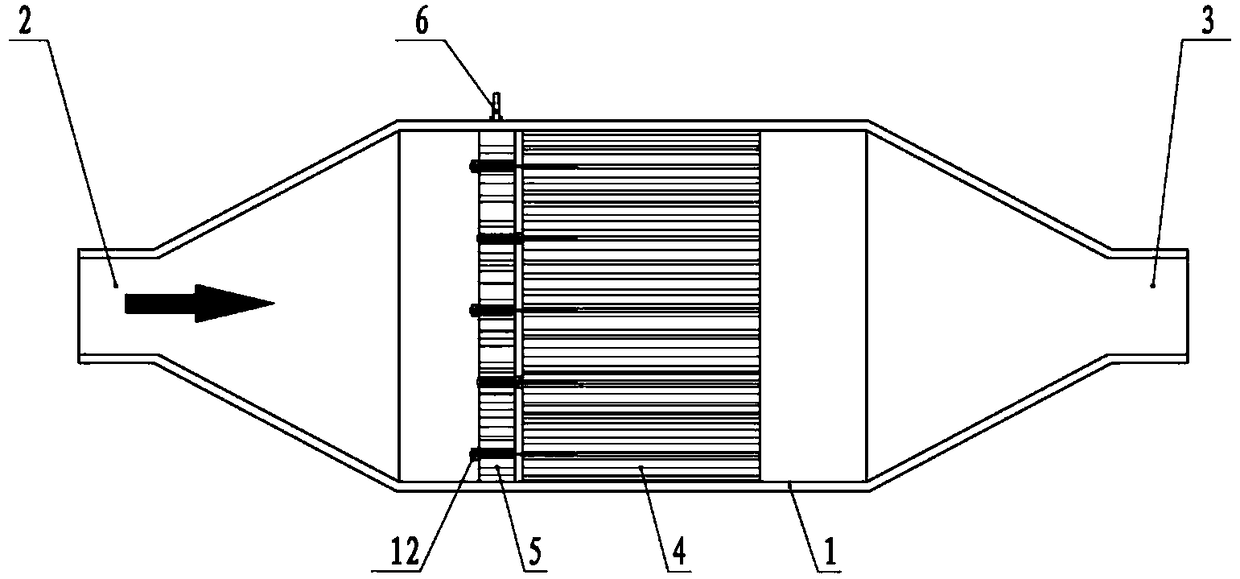

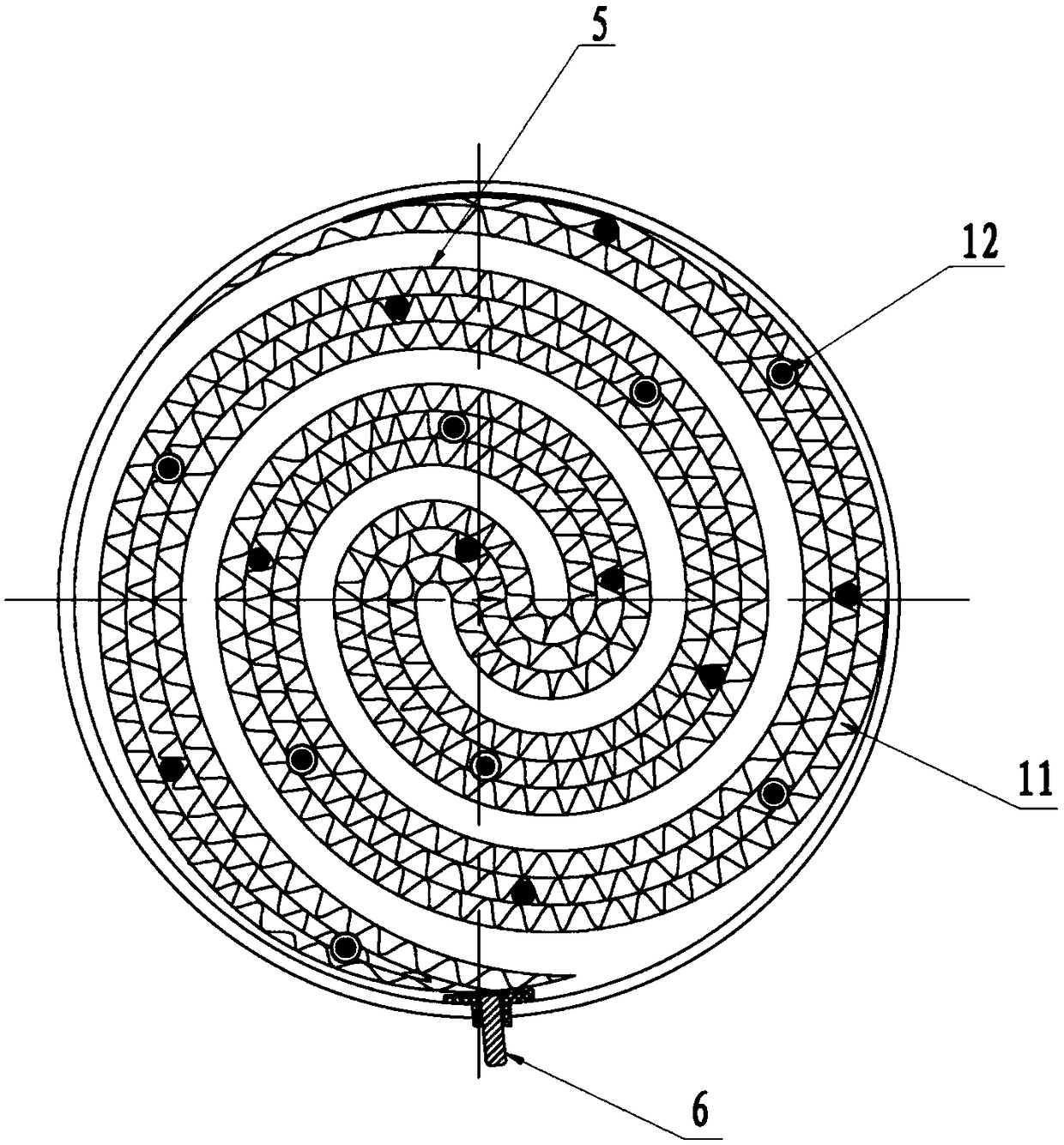

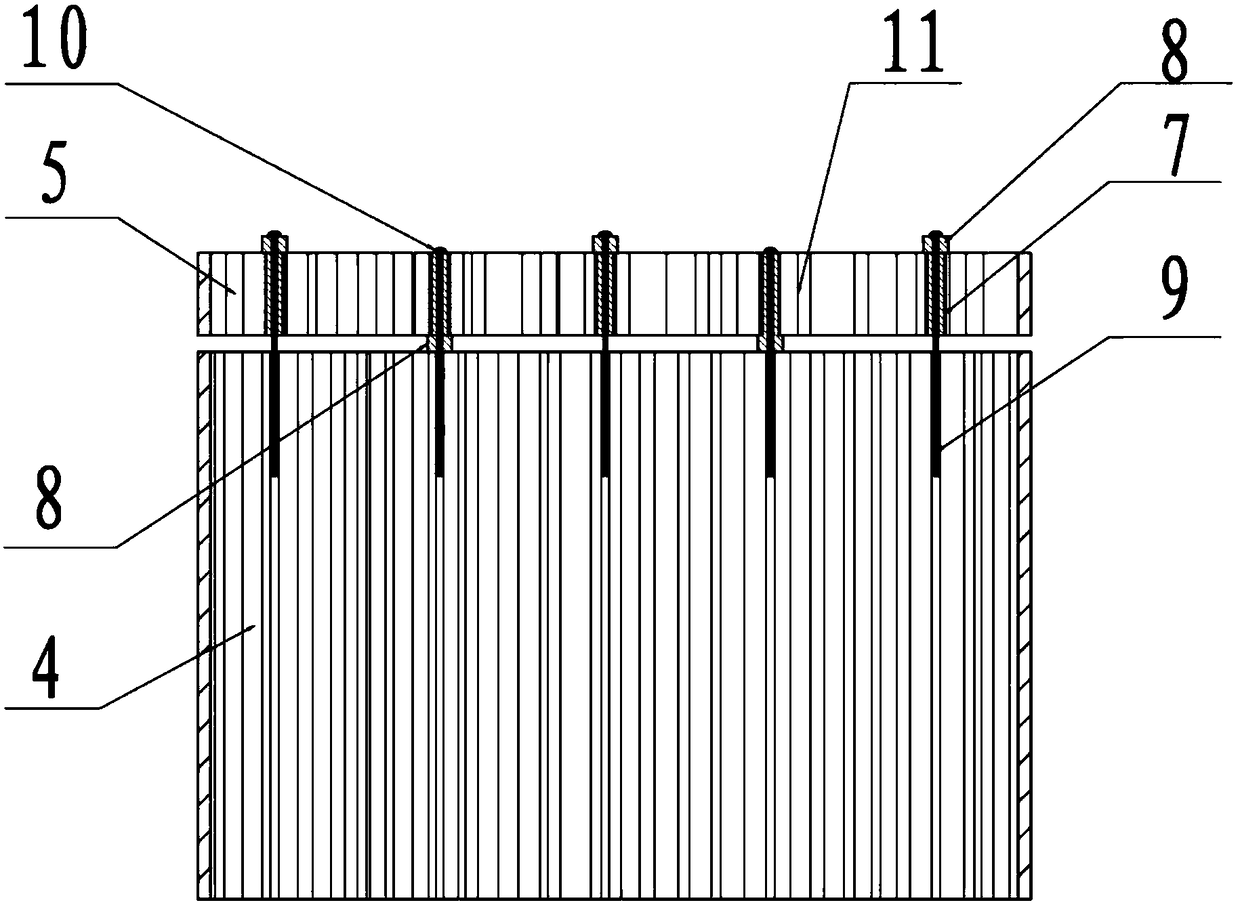

[0025] see Figure 1 to Figure 3 , shows the electric heating element support structure of the present invention and the automobile exhaust gas purification device applying the structure.

[0026] After the automobile exhaust gas purification device is connected to the exhaust outlet of the internal combustion engine of the automobile through the intake pipe, it has an airtight casing 1, and the casing 1 includes a cylindrical middle section and tapers outward from the front and rear ends of the middle section. Conical shape, the front and rear ends respectively have an air inlet 2 and an exhaust port 3, the air inlet 2 communicates with the intake pipe, and the exhaust port 3 communicates with the exhaust pipe, as figure 1 As shown, an electric heating element and a metal catalyst carrier 4 are sequentially provided in the middle section of the housing 1 along the flow direction of the exhaust gas, and the electric heating element includes a heating core 5 and an electrical c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com