A temperature difference driven turbine

A technology of temperature difference and turbine, which is applied in the direction of automatic clutch, machine/engine, mechanism for generating mechanical power, etc. It can solve the problems of reducing the work efficiency of the temperature difference to rotate the kinetic energy conversion device, etc., to achieve a large temperature difference and avoid the leakage of the working medium , the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

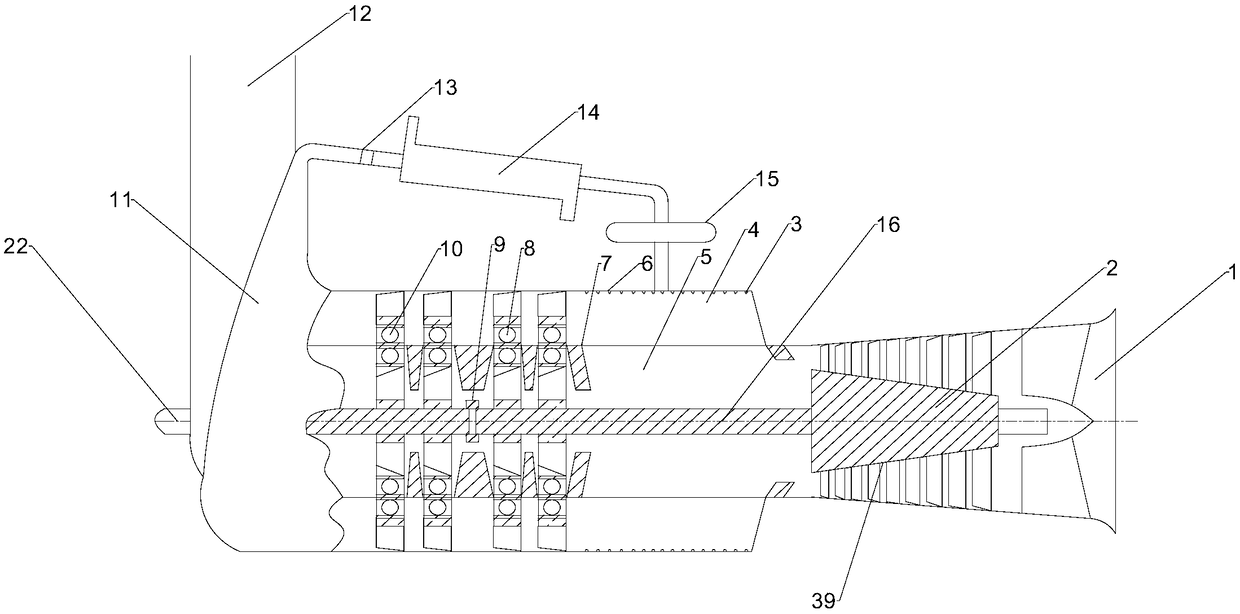

[0039] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto. The diameter of the joint between the shrinking cone-shaped rotary body shell part of the inner shell 7 and the cylindrical cavity is consistent with the diameter of the cavity.

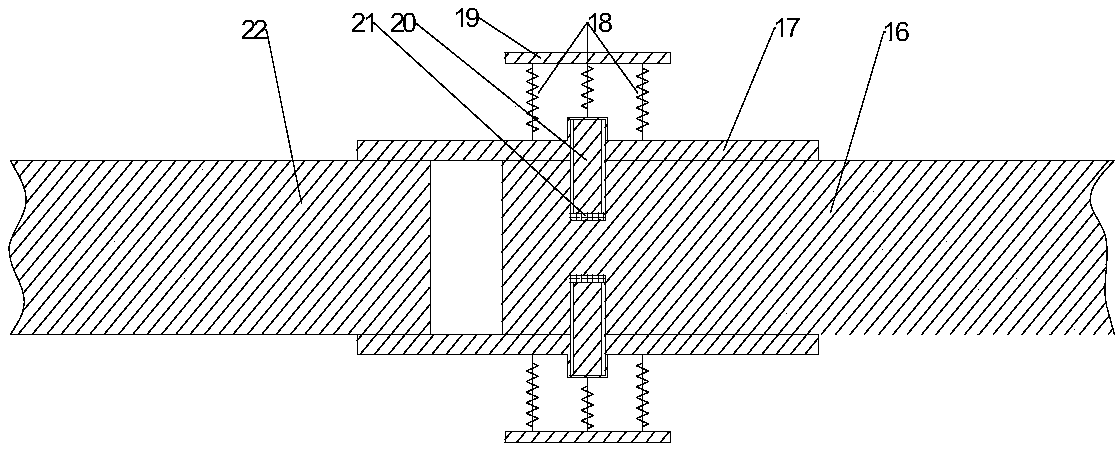

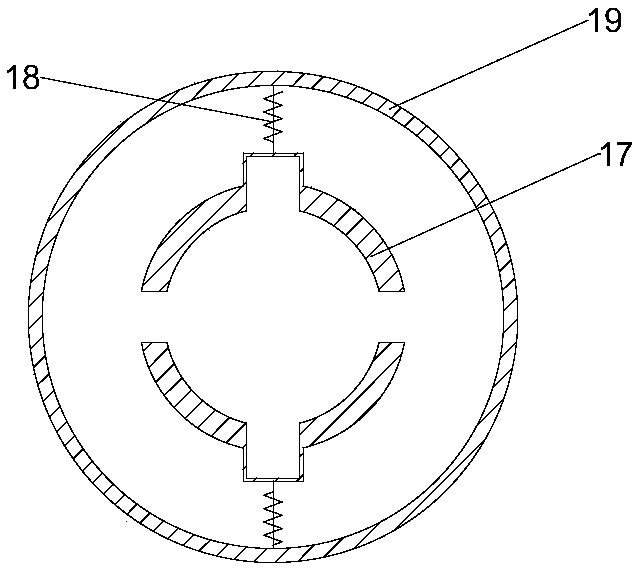

[0040] Such as figure 1 , 4 As shown, a temperature difference driven turbine includes a hot air inlet 1, a hot compressor 2, a working medium nozzle 3, an outer housing space 4, an inner housing space 5, an outer housing 6, an inner housing 7, a low-pressure turbine 8, and a clutch 9. High-pressure turbine 10, guide pipe 11, exhaust duct 12, compressor 13, condensation pipe 14 and storage device 15, compressor main shaft 16, high-pressure turbine main shaft 22; the outer shell 6 is a cylindrical cavity, and the inner shell The body 7 protrudes from the outer shell 6, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com