Air compressor lubricating and cooling system

A technology of air compressors and cooling water pumps, applied in mechanical equipment, engine control, machines/engines, etc., can solve problems such as oil and gas temperature rise, threat to safe operation of production lines, production line loss of pressure and tripping, etc., to ensure safe operation, The effect of overcoming the threat of the production line and the best energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the drawings.

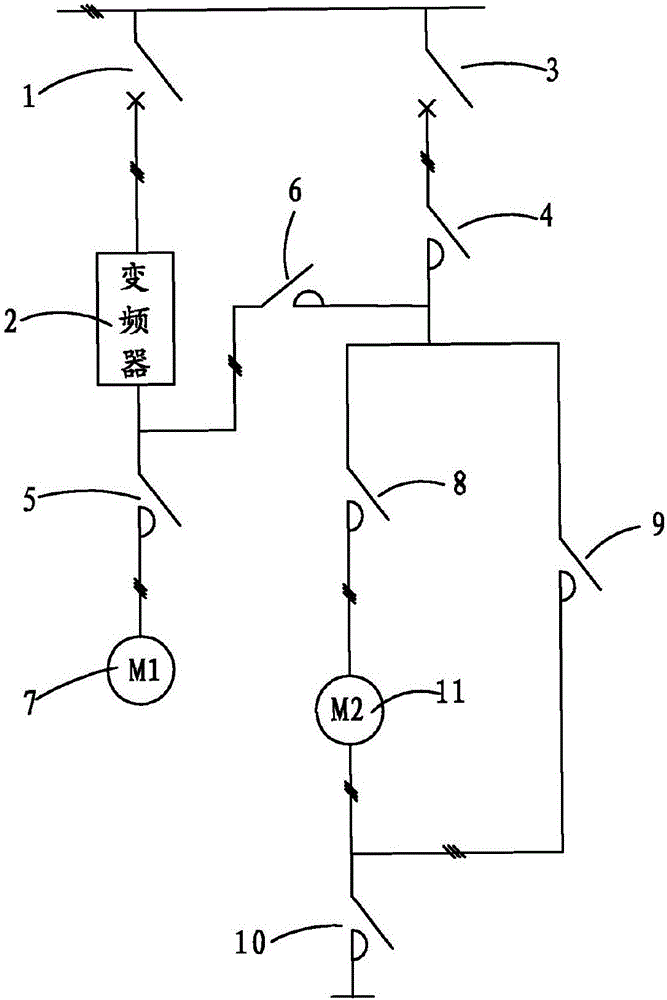

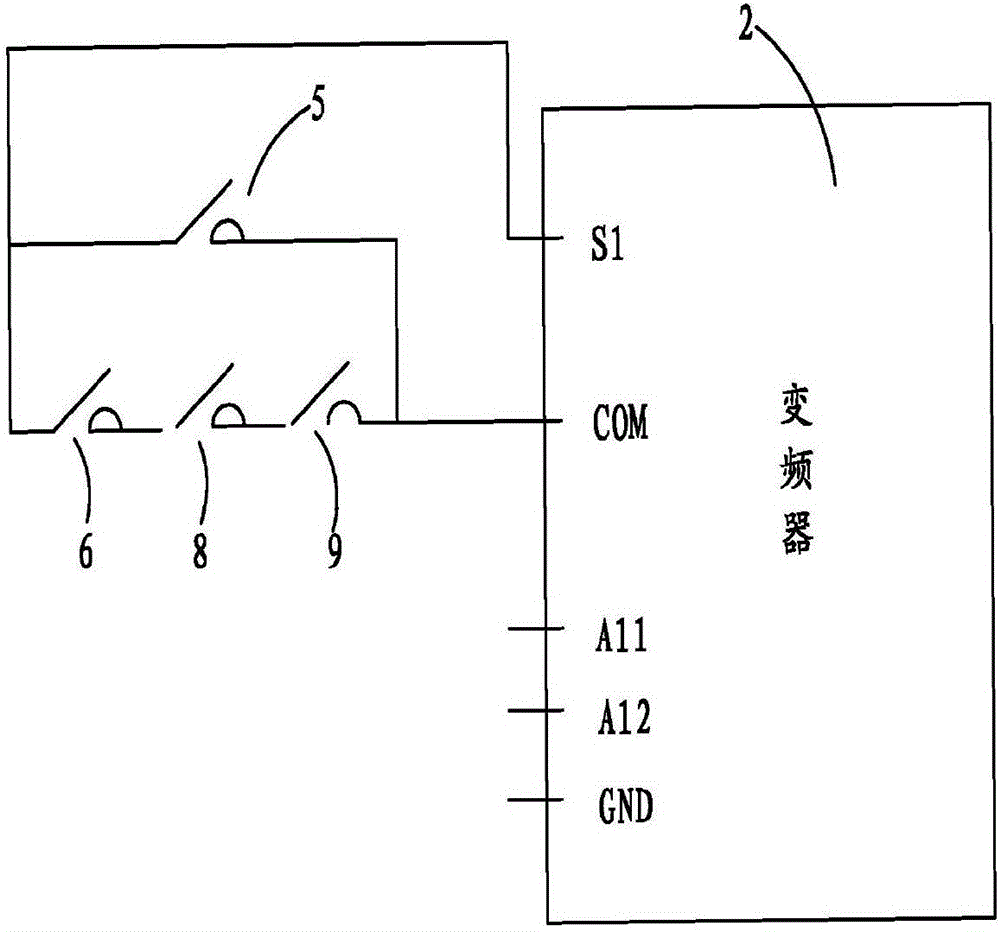

[0015] As shown in Figure 1(a), the electrical main circuit of the cooling water control system of an air compressor of the present invention is as follows: the power cord is connected to the inverter 2 through the circuit breaker 1 and the AC contact through the circuit breaker 2 3 The other end of the frequency converter 2 is connected to one end of the AC contactor one 5 and the one end of the AC contactor zero 6. The other end of the AC contactor one 5 is connected to the water pump motor one 7. The AC contactor The other ends of AC contactor zero 6, AC contactor two 4 are connected to each other, one end of AC contactor four 8 and AC contactor five 9 are both connected to the connection node of AC contactor zero 6, AC contactor two 4, AC contactor The other end of the four is connected to the head end of the three windings of the water pump motor two 11, and the other end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com