A device and method for drying garbage using heat generated by garbage incineration

A waste incineration and drying device technology, which is applied in the direction of combustion methods, incinerators, combustion types, etc., can solve the problems of low calorific value, waste of heat energy, and large heat consumption, so as to reduce the concentration and emission of smoke and dust, and reduce the content of dust , The effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

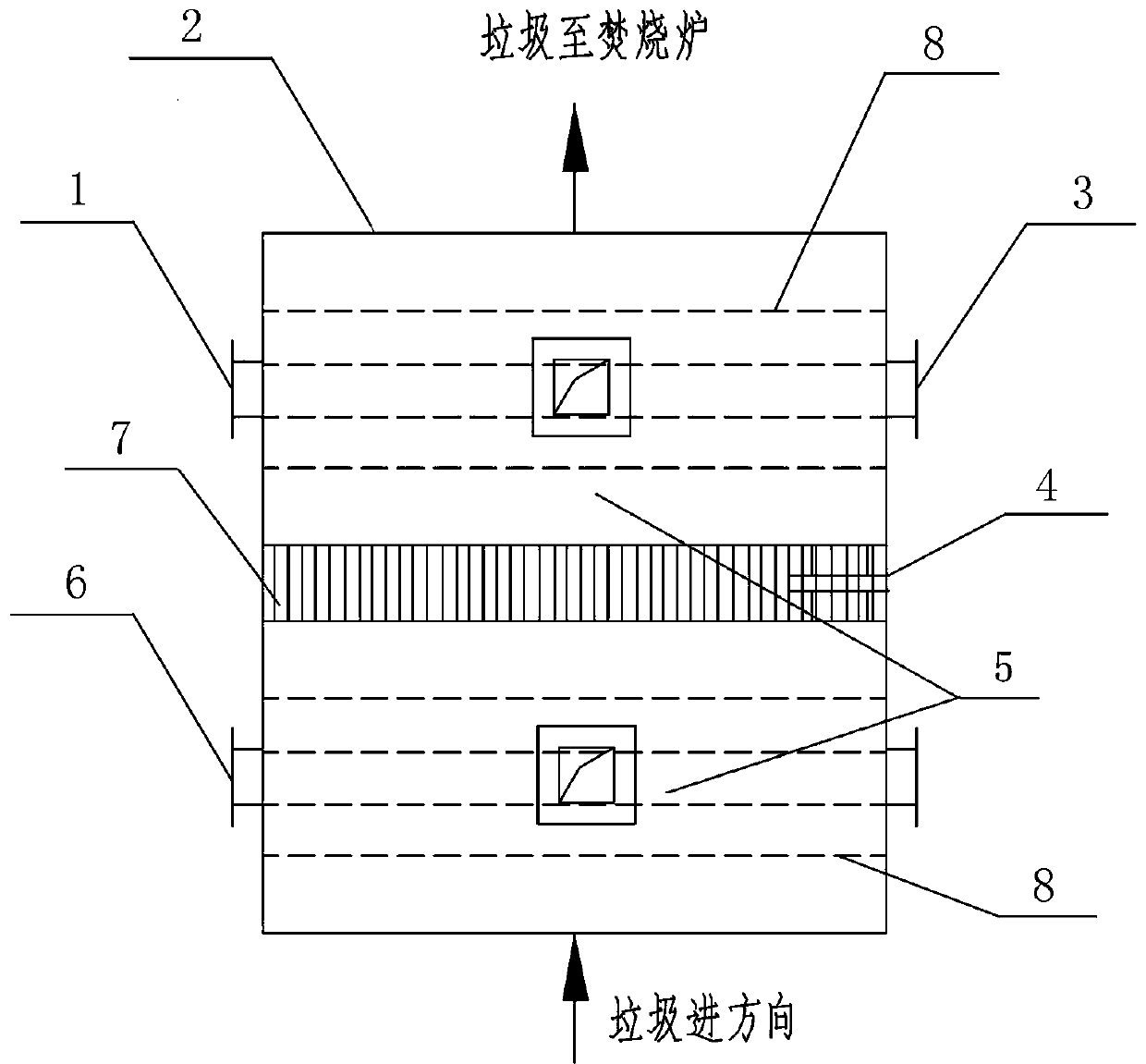

[0026] A device for drying garbage by using the heat generated by garbage incineration, which is composed of two flue gas waste heat utilization devices (3) connected in series. The flue gas waste heat utilization device is a hollow box, and the inner wall of the top of the box A heat conduction plate (8) is provided; a screen (7) is provided between two adjacent flue gas waste heat utilization devices, and the upper surface of the screen and the upper surface of the flue gas waste heat utilization device are arranged on the same plane, The upper surface of the screen and the upper surface of the flue gas waste heat utilization device are jointly used as a heat transfer surface (5) for spreading and drying garbage; the flue gas pipe (4) is passed between two adjacent flue gas waste heat utilization devices connected; the flue gas waste heat utilization device is provided with a flue gas inlet (1) and / or flue gas outlet (6); the bottom of the flue gas waste heat utilization devi...

Embodiment 2

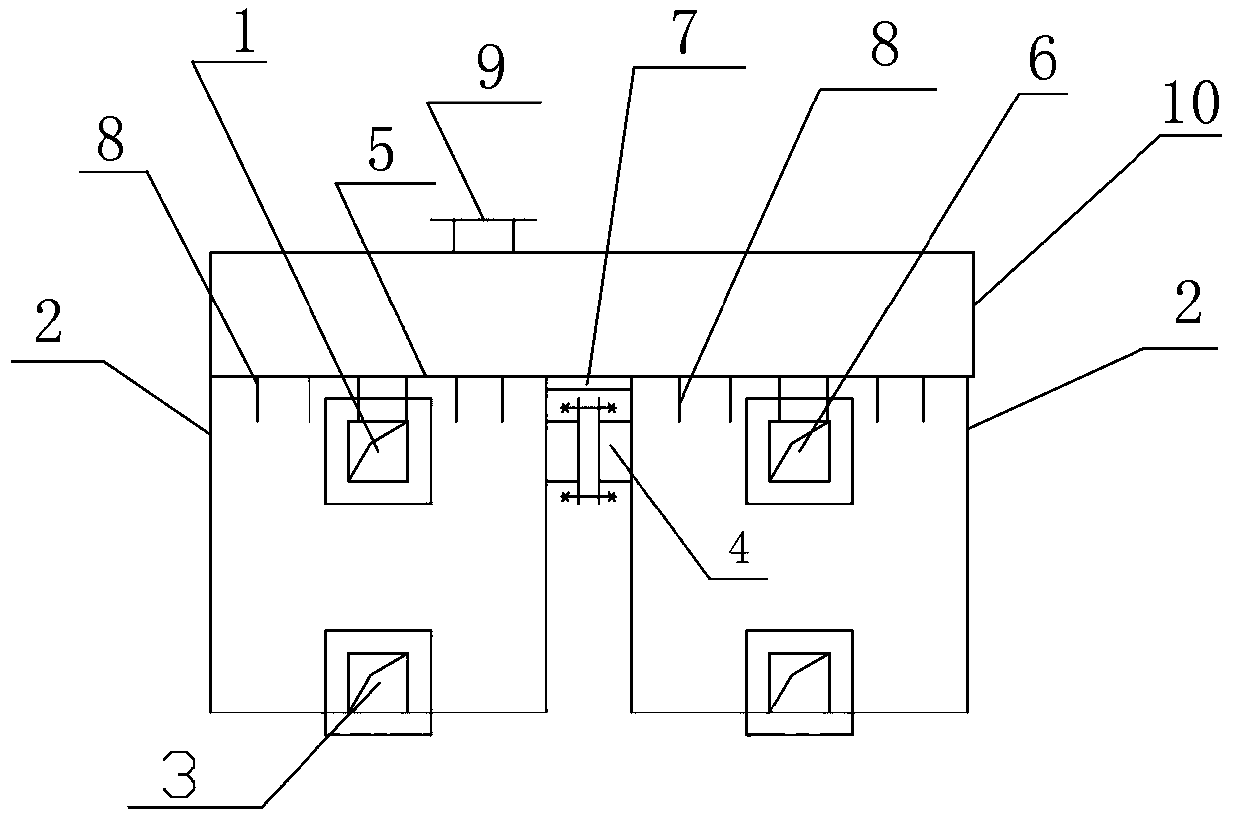

[0033] A device for drying garbage by using the heat generated by garbage incineration. It is composed of six flue gas waste heat utilization devices connected in series. The flue gas waste heat utilization device is a hollow box with a heat conduction plate; a screen is arranged between two adjacent flue gas waste heat utilization devices, and the upper surface of the screen and the upper surface of the flue gas waste heat utilization device are arranged on the same plane, and the upper surface of the screen and the flue gas The upper surface of the waste heat utilization device is jointly used as a heat transfer surface for spreading and drying garbage; two adjacent flue gas waste heat utilization devices are connected through a flue gas pipe; the flue gas waste heat utilization device is equipped with a flue gas inlet and / or flue gas outlet; a slag outlet is provided at the bottom of the flue gas waste heat utilization device.

[0034] The section of the flue gas inlet is c...

Embodiment 3

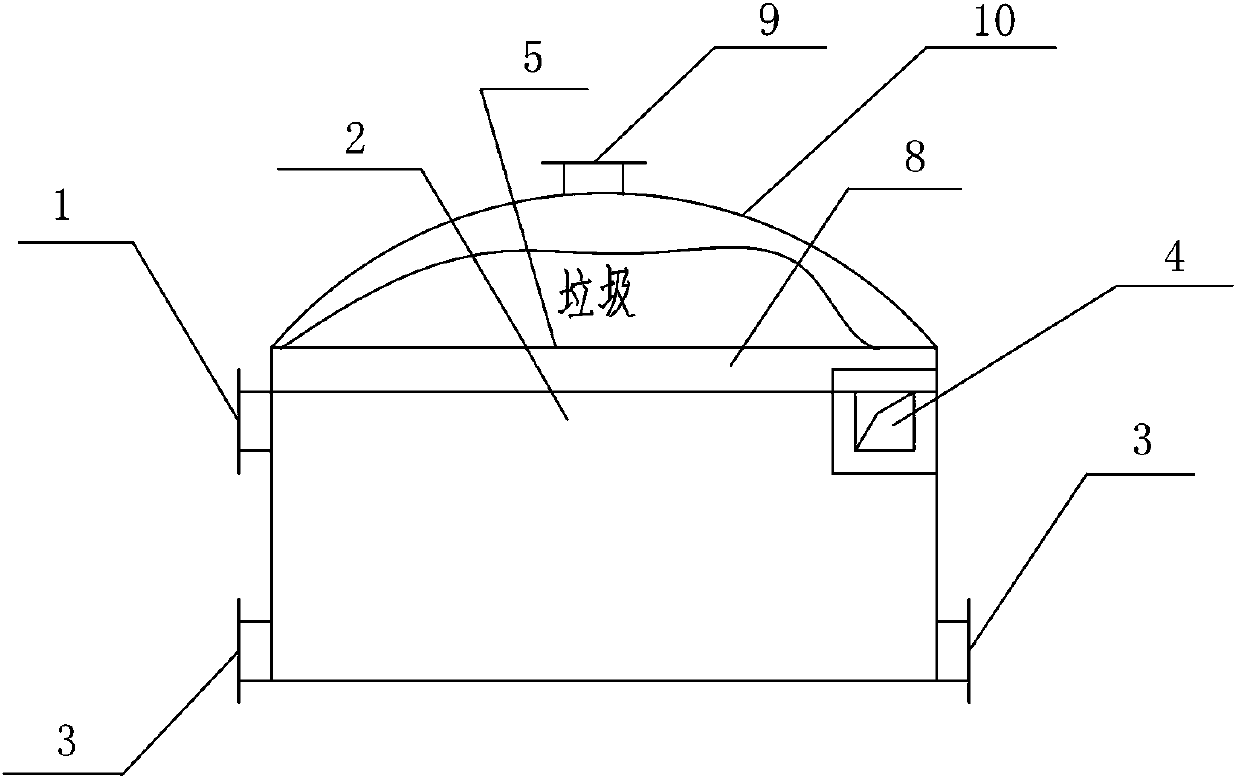

[0040] A device for drying garbage by using the heat generated by garbage incineration. It is composed of 12 flue gas waste heat utilization devices connected in series. The flue gas waste heat utilization device is a hollow box with a heat conduction plate; a screen is arranged between two adjacent flue gas waste heat utilization devices, and the upper surface of the screen and the upper surface of the flue gas waste heat utilization device are arranged on the same plane, and the upper surface of the screen and the flue gas The upper surface of the waste heat utilization device is jointly used as a heat transfer surface for spreading and drying garbage; two adjacent flue gas waste heat utilization devices are connected through a flue gas pipe; the flue gas waste heat utilization device is equipped with a flue gas inlet and / or flue gas outlet; a slag outlet is provided at the bottom of the flue gas waste heat utilization device.

[0041] The section of the flue gas inlet is ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com