Preheating structure, preheating system and preheating method for compressor and air conditioner

A compressor preheating and compressor technology, used in heating methods, air conditioning systems, space heating and ventilation, etc. The effect of reducing the time of low-speed operation, avoiding self-protection, and improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

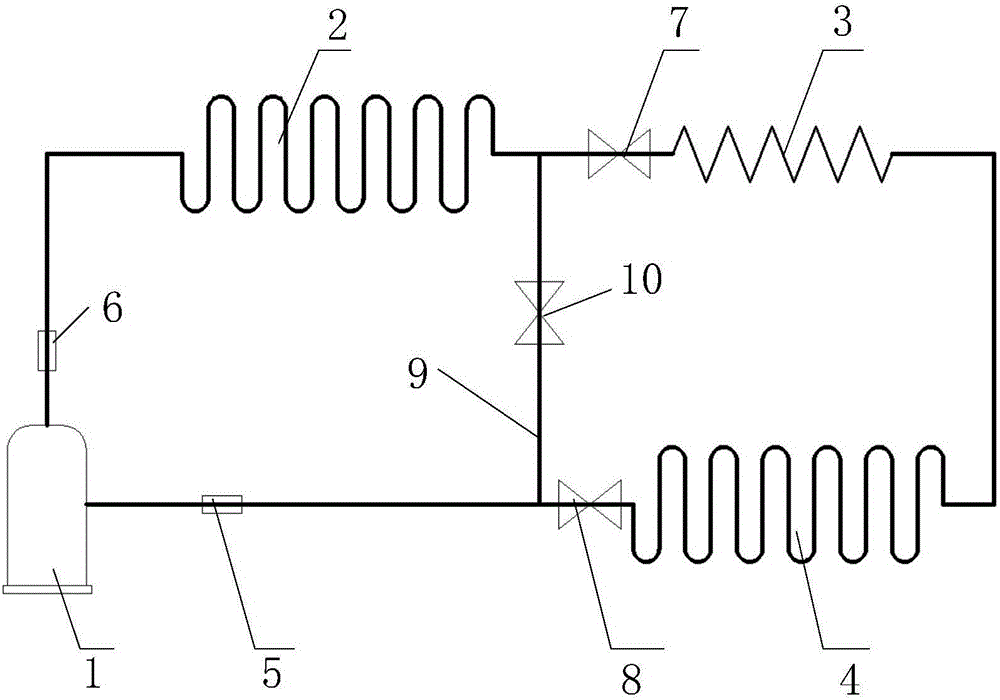

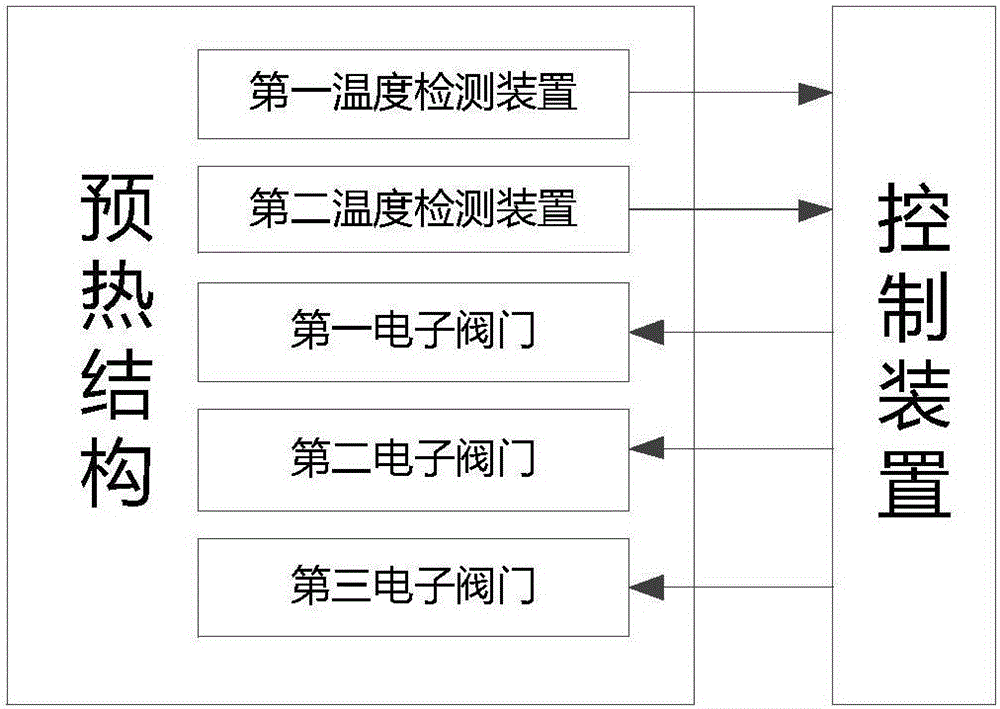

[0059] figure 1 It is a structural schematic diagram of a compressor preheating structure in Embodiment 1 of the present invention, including a compressor 1, an outdoor condenser 2, a capillary tube 3 and an indoor evaporator 4, and the exhaust port of the compressor 1 is connected to the air intake of the outdoor condenser 2 The outlet of the outdoor condenser 2 is connected to the capillary 3, and the capillary 3 is connected to the air return port of the compressor 1 through the indoor evaporator 4, and the air return port is provided with a first temperature detection device 5 for detecting the return air temperature of the compressor; A first electronic valve 7 is provided between the outdoor condenser 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com