Water seepage testing device for optical cable

A test device and optical cable technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc., can solve the problem of not being able to satisfy multiple batches and specifications of optical cable samples at the same time, affecting the accuracy of measurement results, and difficult to control the water level, etc. problems, to achieve low production costs, improve test efficiency and accuracy, and improve test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

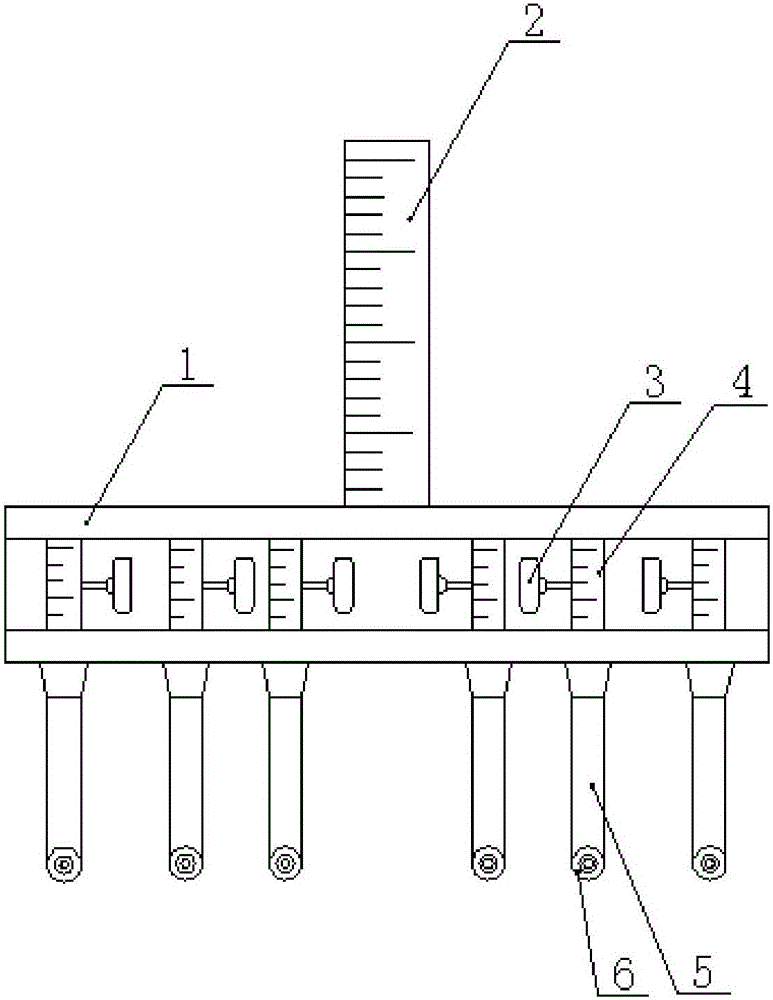

[0021] Optical cable water penetration test device, such as figure 1 As shown, the device comprises a stainless steel water storage tank 1, a water pipe and an elastic connection hose 5, and the stainless steel water storage tank is equipped with the water pipe and the elastic connection hose.

[0022] The water pipe includes a main water pipe 2 and a water distribution pipe 4, the main water pipe is vertically installed in the center of the upper surface of the stainless steel water storage tank, the upper port of the main water pipe is opened to communicate with the atmosphere, and the upper and lower parts of the stainless steel water storage tank Several water distribution pipes are installed vertically and parallelly between them. Sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com