Bonding structure life prediction method of high-speed motor train unit

A high-speed EMU and life prediction technology, which is applied in the direction of railway vehicle testing, etc., can solve problems such as unclear bonding structure adhesive layer strength, failure to meet the use requirements, and inability to predict the bonding strength design of the bonding structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

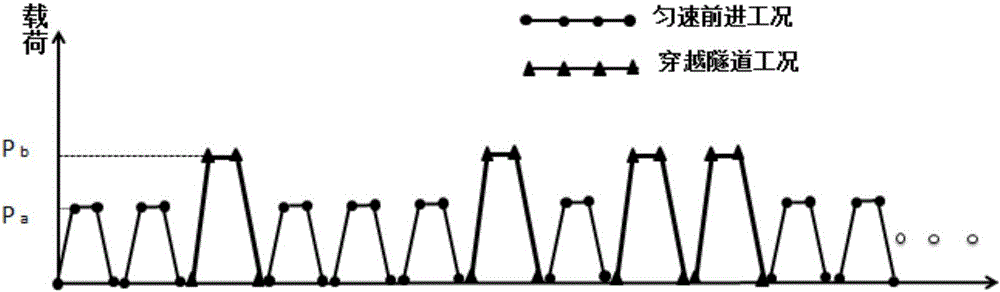

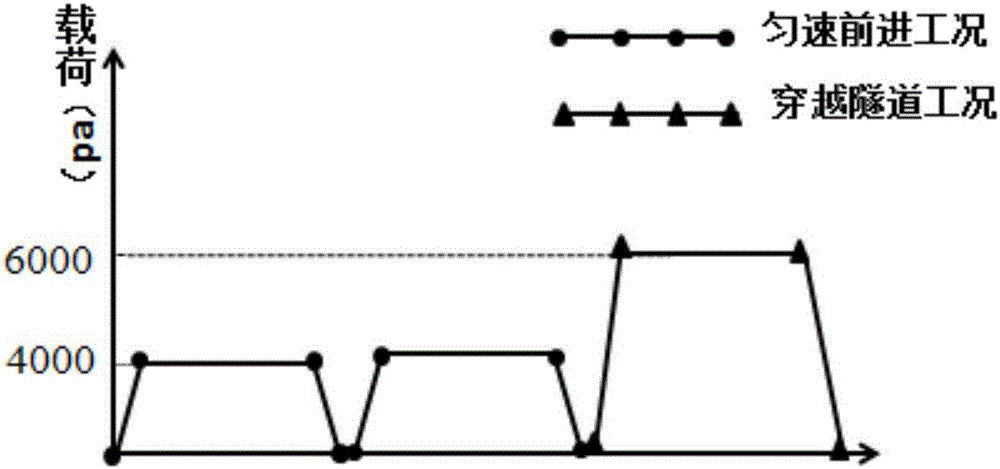

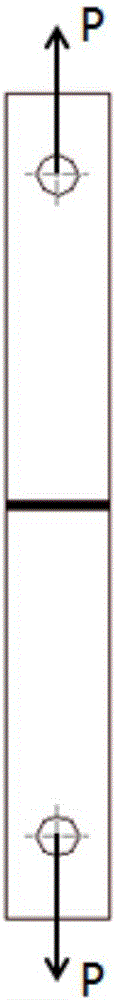

[0039] The present invention provides a method for predicting the life of a bonded structure of a high-speed EMU, which needs to establish the relationship L=Φ between the mileage L of the high-speed EMU and the number of cycles Q of the dynamic load spectrum of the test bonded specimen under the test condition of alternating climate (Q), the specific process is as follows:

[0040] First, according to the specific structural model of the high-speed EMU, the overall simulation model of the body structure and the local simulation model of the bonding structure to be predicted are established. The operating environment, the number of stops, and the number of tunnels crossed by the typical lines of high-speed EMUs are counted, and the number A of stops and the number B of tunnel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com