A visual test device used for low-temperature liquified gas

A low-temperature liquefied gas and test device technology, which is applied to measuring devices, material analysis through optical means, instruments, etc., can solve problems such as limited visual range, inability to meet experimental needs, and inconvenient use, so as to improve the heat preservation effect and achieve good results. Designed for portability and improved visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

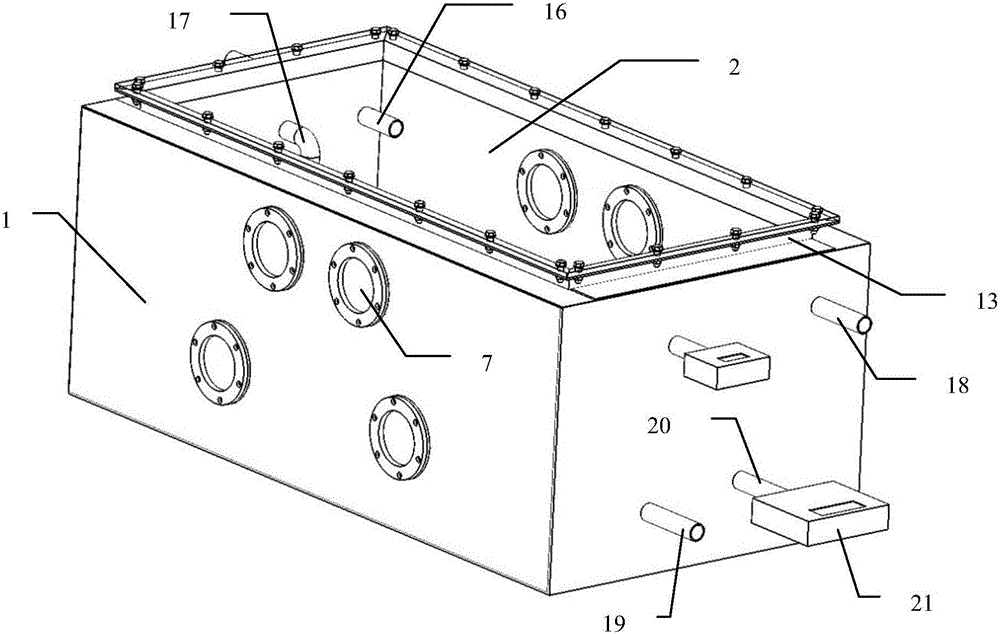

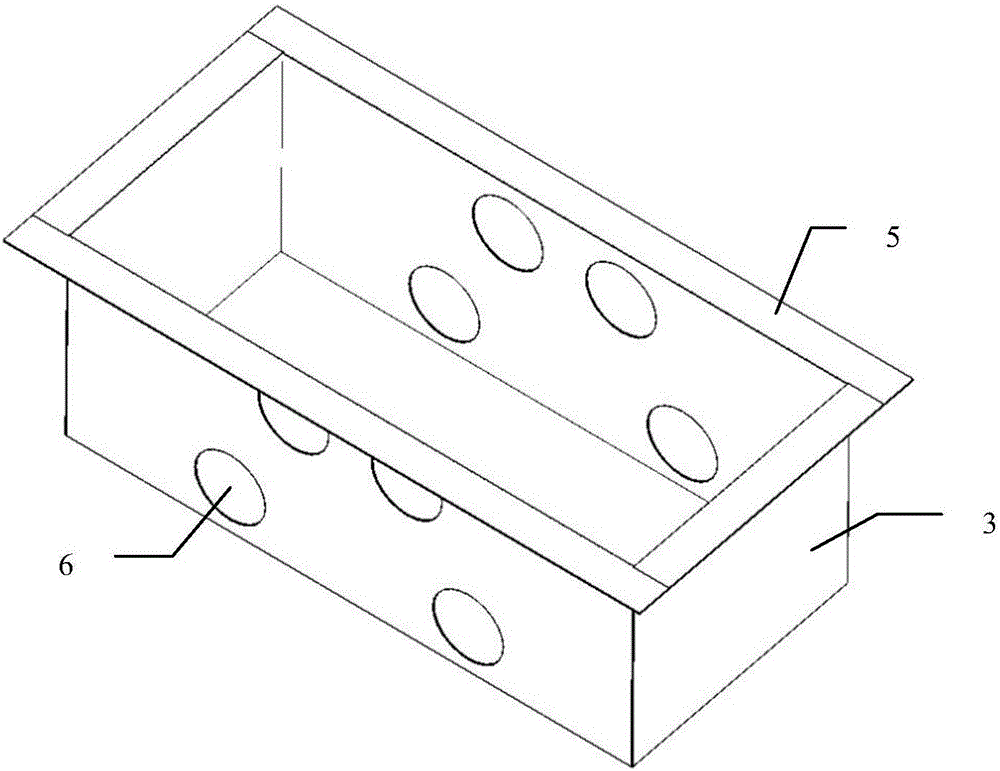

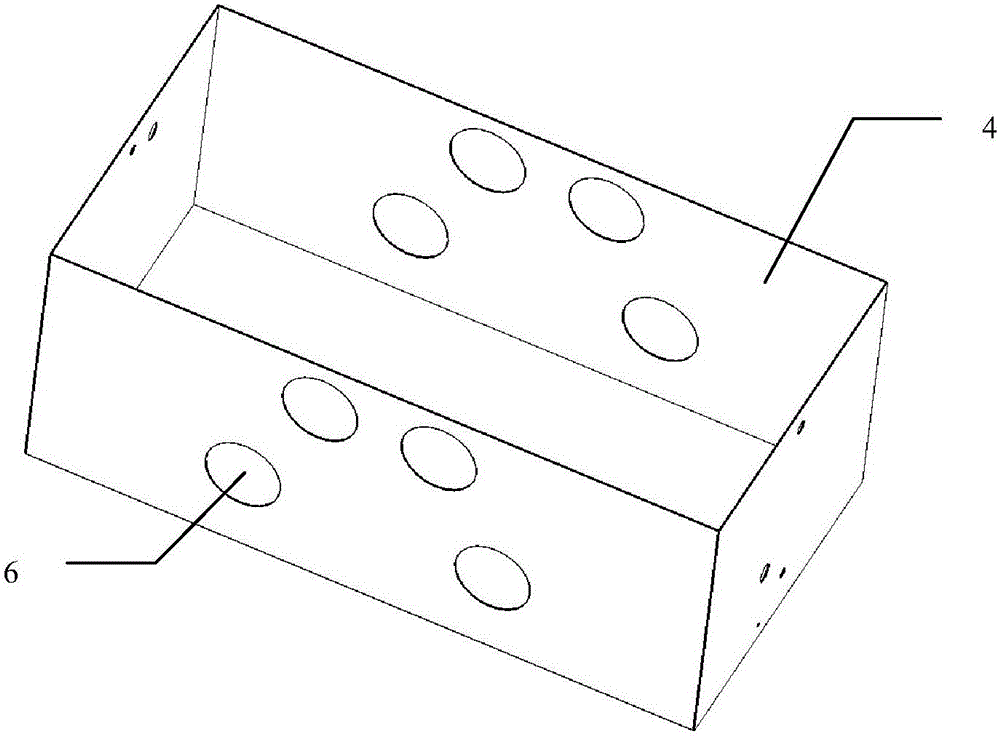

[0033] refer to Figure 1-5 , the preferred embodiment 1 of the present invention provides a visual test device for low-temperature liquefied gas, comprising a cuboid-shaped tank body 1 with an upper opening and a cover plate 2, and the tank body 1 includes an inner tank body 3 and an outer tank body 4 , the middle of the inner tank 3 and the outer tank 4 is provided with an insulating layer, and the four side tops of the inner tank 3 are bent outward at 90 degrees to form the top surface 5 of the tank, and the cover plate 2 is a transparent cover plate and sealed Installed on the top surface 5 of the tank body to form a top observation window; the front and rear sides of the inner tank body 3, the insulation layer and the outer tank body 4 are provided with a number of installation holes 6, and the front and rear sides of the tank body 1 pass through the installation holes 6 A side viewing window 7 is installed, and the side viewing window 7 includes an outer flange 8 on the ...

Embodiment 2

[0044] refer to Image 6, the preferred embodiment 2 of the present invention provides a visual test device for cryogenic liquefied gas, the only difference between it and embodiment 1 is that the structure of the side viewing window 7 is different, the side viewing window of this embodiment will be connected with the outer flange The connected transparent glass window is arranged as a concave transparent window 23, and its concave bottom surface, that is, the visible surface parallel to the inner transparent glass window, is as close as possible to the transparent glass window on the inner flange, and the fixed concave transparent window 23 The end cover is provided with a see-through plate 22, and the see-through plate 22 and the concave see-through window 23 form an internal sealed space, which can be vacuumed or filled with an inert gas. The cable is connected to an external monitor.

[0045] In this embodiment, the distance between the external window and the internal wi...

Embodiment 3

[0047] refer to Figure 7-8 , the preferred embodiment 3 of the present invention provides a visual test device for low-temperature liquefied gas, the only difference between it and embodiment 1 is that one or two side observation windows are replaced with the side heating windows of the cost embodiment, that is, the In the above-mentioned side heating window, the transparent glass window connected with the outer flange is set as a concave transparent window 23, and the transparent glass window connected with the inner flange is replaced with a heater, and the heater includes a right-side closed Heat conduction cylinder 26, the circumferential side of the heat conduction cylinder 26 is evenly provided with a number of heat conduction fins 28, the inside of the heat conduction cylinder 26 is provided with a heat collector 27, the heat collector 27 is connected to the heating fin 29, and the heating fin 29 passes through The connecting wire in the connecting pipe 30 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com