Visual detection system for health-care protective article mask

A protective equipment and visual inspection technology, applied in the field of optical inspection, can solve the problems of insufficient detection effect, mixed defective products, simple and rough structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

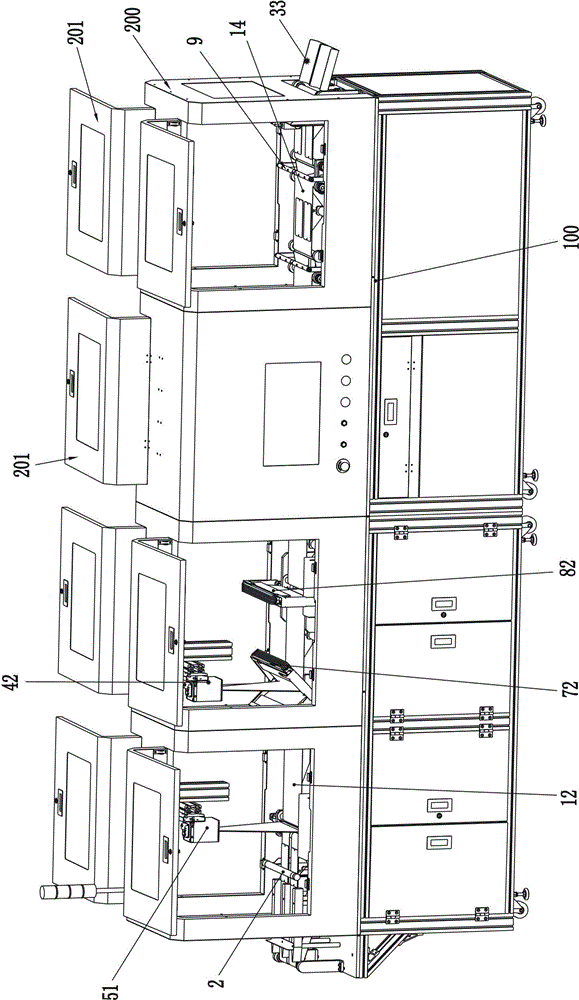

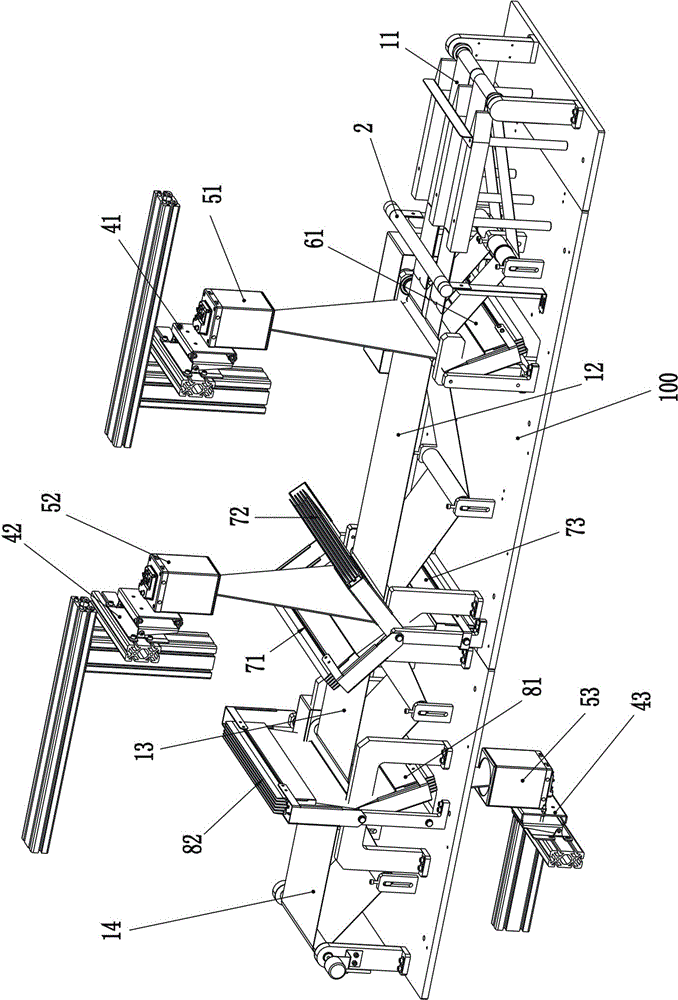

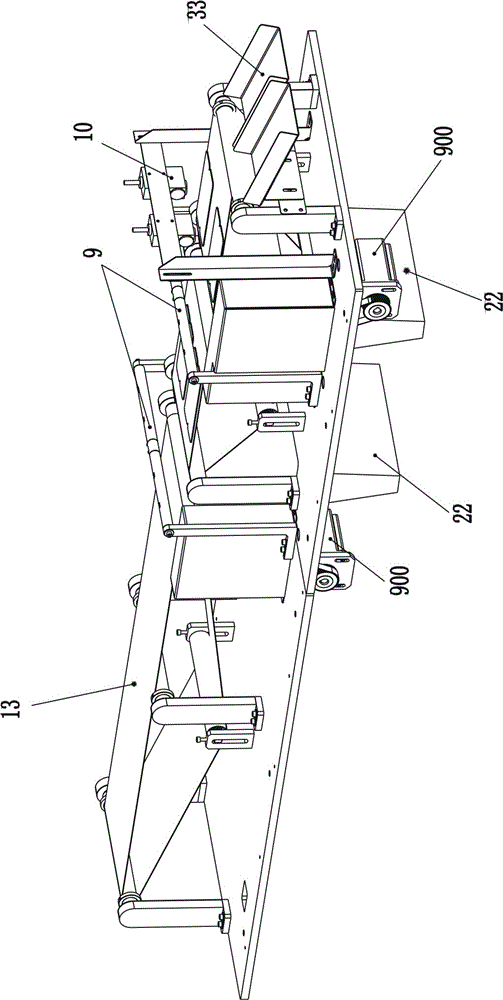

[0028] The present invention will be further described below in conjunction with the embodiments and accompanying drawings (1 to 7).

[0029] The visual inspection system for masks of health and medical protective articles involved in the present invention includes a control system (not shown) and a frame 100, on which a conveying device, a first detection device, a second detection device, The third detection device, the waste discharge device, the conveying device, the first detection device, the second detection device, the third detection device, and the waste discharge device are respectively electrically connected to the control system. The conveying device includes a conveying belt and a static removing component 2, and the static removing component 2 is fixed above the conveying belt. The first detection device, the second detection device, and the third detection device constitute a detection process, and the conveyor belt runs through the entire detection process.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com