Tape for semiconductor wafer processing and semiconductor wafer processing method

A wafer processing and processing method technology, applied in the field of tapes for semiconductor wafer processing, can solve the problems of adhesive residue, leakage, fusion bonding of working discs, etc., and achieve the effect of excellent relaxation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

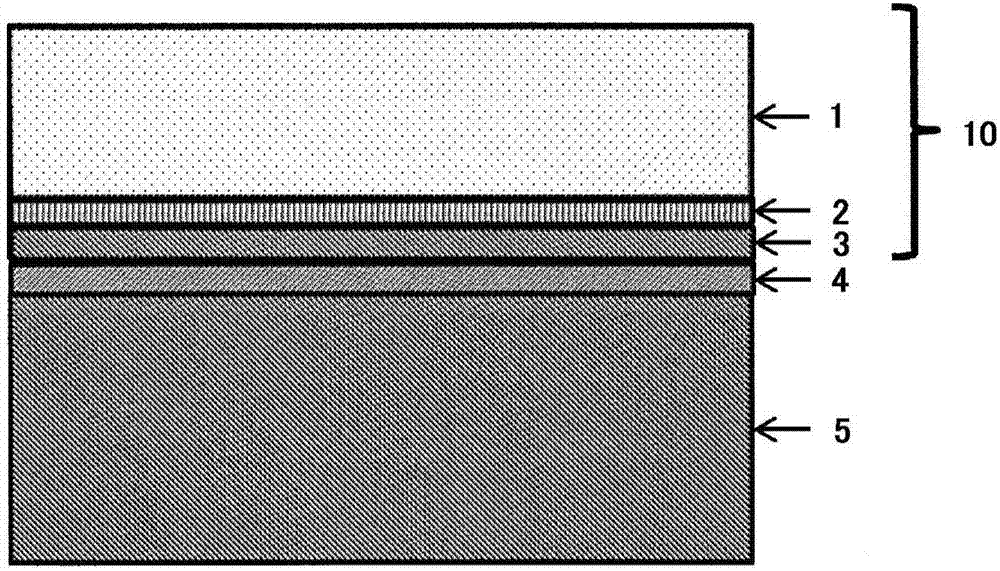

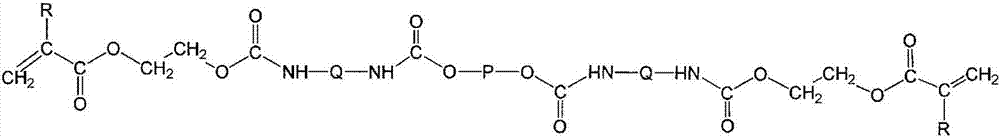

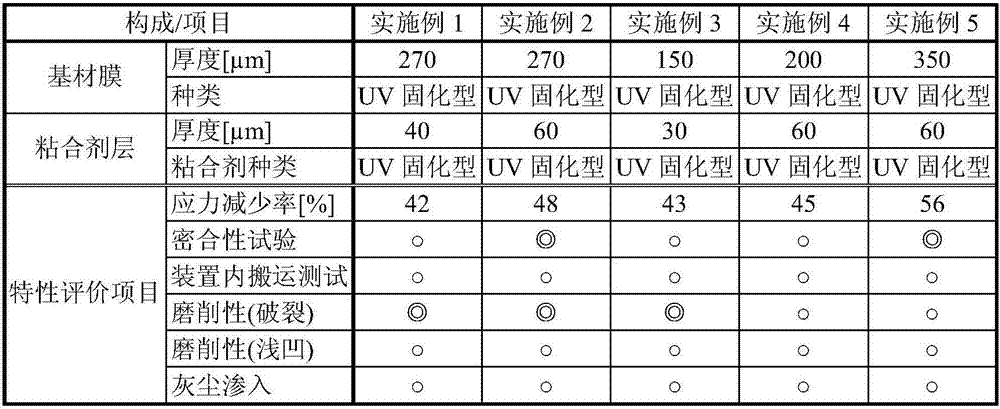

[0113] An acrylic copolymer composed of 2-ethylhexyl acrylate (78mol%), 2-hydroxyethyl acrylate (21mol%), and methacrylic acid (1mol%) was prepared, after which the acrylic acid The hydroxyl group in the repeating unit obtained from 2-hydroxyethyl ester reacts with 2-(methacryloyloxy)ethyl isocyanate to obtain a carbon-carbon double bond that is radiation-curable on the side chain of the polymer. Functional methacryloyl acrylic copolymer. In the obtained acrylic copolymer, a trifunctional ultraviolet curing type urethane acrylate oligomer (manufactured by Nippon Synthetic Chemicals Co., Ltd., (trade name) Violet 75 parts by mass of UV-7550B) and 5.0 parts by mass of a photopolymerization initiator ((trade name), manufactured by BASF JAPAN Co., Ltd., Irgacure 184) to obtain an adhesive composition.

[0114] Apply the following adhesive a mainly composed of (meth)acrylic copolymer on a 25 μm polyethylene terephthalate (PET) spacer, and dry it at 120°C for 2 minutes to set the t...

Embodiment 2

[0117] The above-mentioned adhesive a was coated on a 25 μm polyethylene terephthalate spacer, dried at 120°C for 2 minutes to form an adhesive layer with a thickness of 60 μm, and the adhesive layer was bonded to A tape for semiconductor wafer processing was produced on a substrate film made of the above-mentioned urethane acrylate having a thickness of 270 μm.

Embodiment 3

[0119] The above-mentioned adhesive a was coated on a 25 μm polyethylene terephthalate spacer, dried at 120°C for 2 minutes to form an adhesive layer with a thickness of 60 μm, and the adhesive layer was bonded to A tape for semiconductor wafer processing was produced on a substrate film made of the above-mentioned urethane acrylate having a thickness of 100 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com