Meat product colorant and preparation method thereof

A technology for colorants and meat products, which is applied in the field of meat product colorants and its preparation, can solve problems such as poor color stability, impact on application, fading, etc., achieve improved safety, solubility and stability, and reduce nitrite residual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

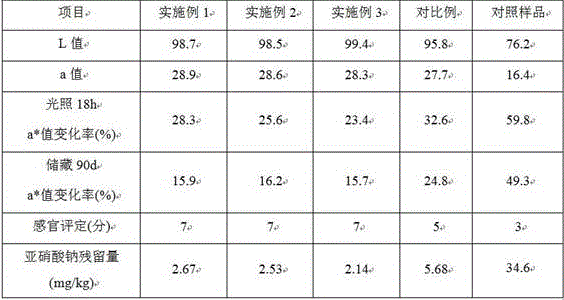

Examples

Embodiment 1

[0019] A coloring agent for meat products, comprising the following components in parts by weight: 80 parts of glycosylated hemoglobin pigment, 5 parts of erythrosine, 10 parts of mulberry red and 3 parts of sodium erythorbate.

[0020] The preparation method of the meat product coloring agent comprises the following steps:

[0021] (1) Healthy fresh pig blood was added with 5% sodium citrate for anticoagulation, centrifuged at 3000r / min for 25min, the lower layer of blood cell fluid was removed, and distilled water was added to high-speed mechanical stirring to break the wall for 2h, and 1% isoascorbic acid and 0.3% hypoascorbic acid were added. Sodium nitrate, 3% glucose, after mixing, stir at 65°C for 40 minutes, cool to room temperature, adjust the pH value to 5.0, centrifuge at 25°C for 5 minutes, pour off the upper solution, and freeze-dry the lower precipitate to obtain glycosylation hemoglobin pigment;

[0022] (2) Mix the glycosylated hemoglobin pigment, erythrosine,...

Embodiment 2

[0024] A meat product coloring agent comprises the following components in parts by weight: 80 parts of glycosylated hemoglobin pigment, 15 parts of erythrosine, 3 parts of mulberry red and 10 parts of sodium erythorbate.

[0025] The preparation method of the meat product coloring agent comprises the following steps:

[0026] (1) Healthy fresh pig blood was added with 8% sodium citrate anticoagulant, centrifuged at 3000r / min for 25min, the lower layer of blood cell fluid was removed, and distilled water was added to high-speed mechanical stirring to break the wall for 2h, and 1% isoascorbic acid and 0.3% hypoascorbic acid were added. Sodium nitrate, 3% glucose, after mixing, stir at 80°C for 20 minutes, cool to room temperature, adjust the pH value to 5.0, centrifuge at 25°C for 5 minutes, pour off the upper solution, and freeze-dry the lower precipitate to obtain glycosylation hemoglobin pigment;

[0027] (2) Mix the glycosylated hemoglobin pigment, erythrosine, mulberry re...

Embodiment 3

[0029] A coloring agent for meat products, comprising the following components in parts by weight: 75 parts of glycosylated hemoglobin pigment, 12 parts of erythrosine, 6 parts of mulberry red and 8 parts of sodium erythorbate.

[0030] The preparation method of the meat product coloring agent comprises the following steps:

[0031] (1) Healthy fresh pig blood was added with 6% sodium citrate for anticoagulation, centrifuged at 3000r / min for 25min, the lower layer of blood cell fluid was removed, and distilled water was added to high-speed mechanical stirring to break the wall for 2h, and 1% isoascorbic acid and 0.3% hypoascorbic acid were added. Sodium nitrate, 3% glucose, after mixing, stir at 70°C for 25 minutes, cool to room temperature, adjust the pH value to 5.0, centrifuge at 25°C for 5 minutes, pour off the upper solution, and freeze-dry the lower precipitate to obtain glycosylation hemoglobin pigment;

[0032] (2) Mix the glycosylated hemoglobin pigment, erythrosine,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com