Preparation method for monodisperse plate-like gold powder

A monodisperse, gold powder technology, used in metal processing equipment, transportation and packaging, etc., can solve the problem of not being able to fully meet the requirements of high-end electronic paste, and achieve the effect of good effect, strong operability and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: The specific content of each substance is: 0.05mol / L of chloroauric acid solution, 1.0mol / L of ascorbic acid, 0.5g / L of linear polyethyleneimine, pH=2.0 of the reducing solution, and the temperature is 40°C. The volume ratio of stock solution is: 1:3.

[0036] Including the following process steps:

[0037] (1) First prepare the chloroauric acid solution and the reducing solution according to the experimental procedures, and adjust the temperature and pH of the reducing solution.

[0038] (2) Under the condition of stirring, slowly add the chloroauric acid solution into the reducing solution, and continue stirring for 60 minutes after adding;

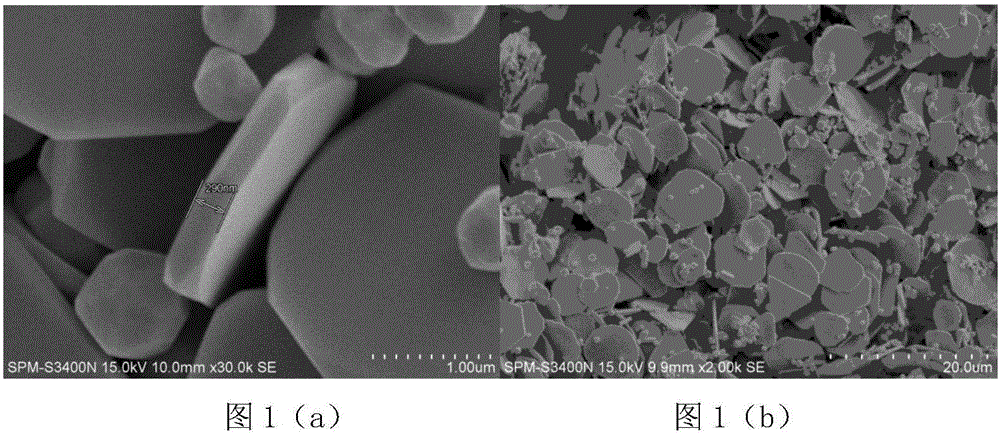

[0039] (3) After repeated washing and freeze-drying of the prepared gold powder, a micron-sized monodisperse flaky gold powder containing partly spherical particles of the present invention is obtained.

[0040] The obtained micron-sized monodisperse flaky gold powder containing part of nearly spherical particles has...

Embodiment 2

[0041] Example 2: The specific content of each substance is: 0.1mol / L of chloroauric acid solution, 2.0mol / L of ascorbic acid, 0.1g / L of linear polyethyleneimine, pH=2.0 of the reducing solution, and the temperature is 40°C. The volume ratio of stock solution is: 1:3.

[0042] Including the following process steps:

[0043] (1) First prepare the chloroauric acid solution and the reducing solution according to the experimental procedures, and adjust the temperature and pH of the reducing solution.

[0044] (2) Under the condition of stirring, slowly add the chloroauric acid solution into the reducing solution, and continue stirring for 60 minutes after adding;

[0045] (3) After repeated washing and freeze-drying of the prepared gold powder, a micron-sized monodisperse flaky gold powder containing partly spherical particles of the present invention is obtained.

[0046] The obtained micron-sized monodisperse flaky gold powder containing part of near-spherical particles has go...

Embodiment 3

[0047] Example 3: The specific content of each substance is: 0.15mol / L of chloroauric acid solution, 1.5mol / L of ascorbic acid, 1.0g / L of linear polyethyleneimine, pH=2.0 of the reducing solution, and the temperature is 40°C. The volume ratio of stock solution is: 1:4.

[0048] Including the following process steps:

[0049] (1) First prepare the chloroauric acid solution and the reducing solution according to the experimental procedures, and adjust the temperature and pH of the reducing solution.

[0050] (2) Under the condition of stirring, slowly add the chloroauric acid solution into the reducing solution, and continue stirring for 60 minutes after adding;

[0051] (3) After repeated washing and freeze-drying of the prepared gold powder, a micron-sized monodisperse flaky gold powder containing partly spherical particles of the present invention is obtained.

[0052]The obtained micron-sized monodisperse flaky gold powder containing part of nearly spherical particles has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com