Valve element steel ball assembling technology

An assembly process and steel ball technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of long adjustment time, high scrapping rate, and low processing efficiency, and achieve short adjustment time, low scrapping rate, and processing high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

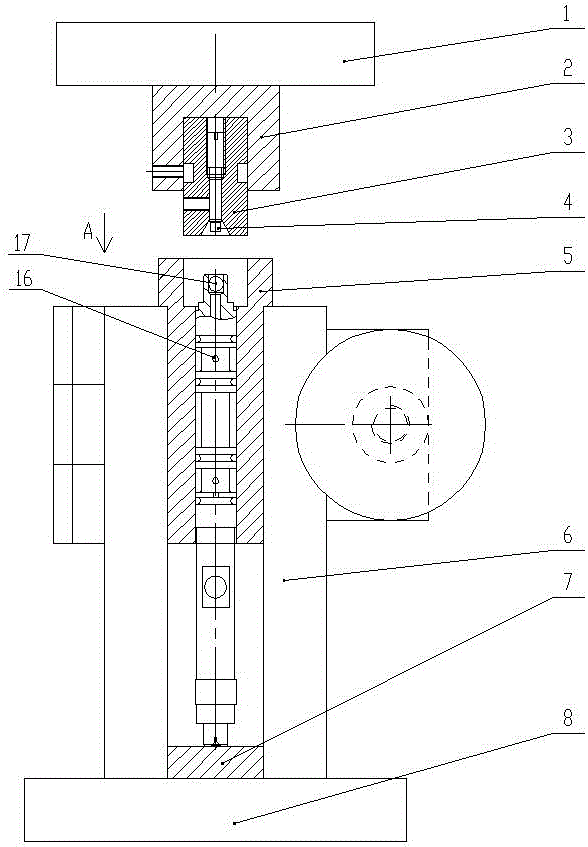

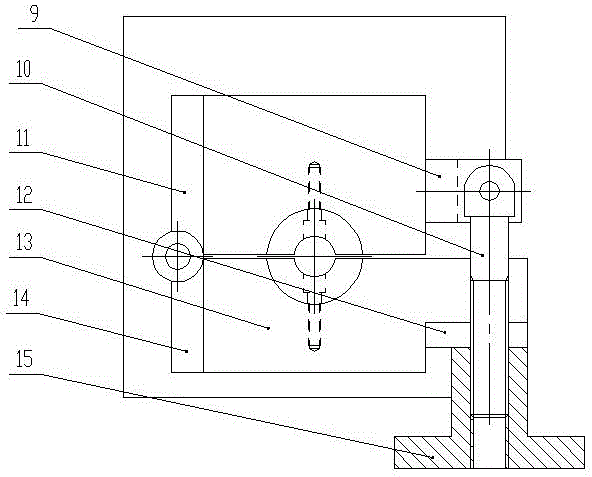

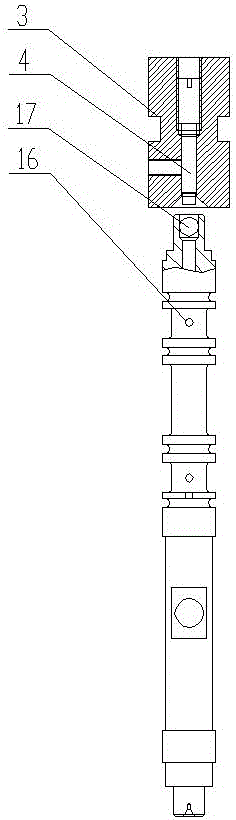

[0042] see Figure 1~Figure 6 , The invention relates to a valve core steel ball assembly and closing device, which includes a bottom plate 8, and a vertical plate 6 is arranged on the bottom plate 8, and the upper section of the vertical plate 6 is connected with a horizontally arranged rear side plate 9. The left end of the rear side plate 9 is provided with a first hinge 11, the front of the rear side plate 9 is provided with a front side plate 13, the left end of the front side plate 13 is provided with a second hinge 14, the first hinge 11 and the second hinge The hinge 14 is coaxially hinged up and down, the middle part of the rear side plate 9 is concave with a semicircular rear mold forward, the middle part of the front side plate 13 is concave with a semicircular front mold, the rear mold and Corresponding to the front mold, the rear mold and the front mold form the valve core back mold 5, the left end of the rear side plate 9 is provided with a screw 10 forward, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap