Recycling pool of muddy water

A technology of water recycling and cement slurry, which is applied in cement mixing devices, flocculation/sedimentation water/sewage treatment, settling tanks, etc., can solve the problems of unfavorable comprehensive utilization of cement slurry water, etc., and achieve the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

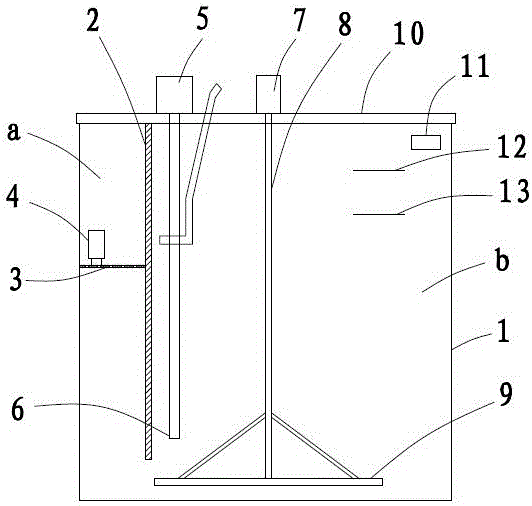

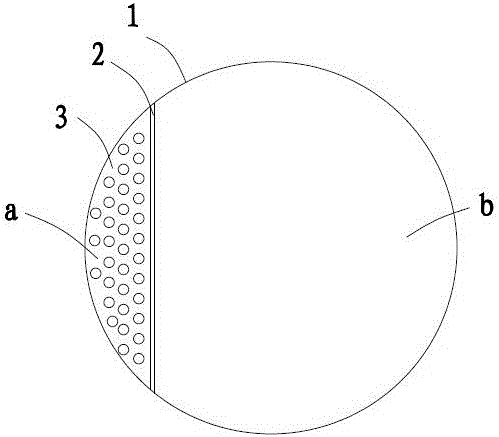

[0021] Embodiment: a kind of cement slurry water recovery pond, as figure 1 shown. The device comprises a circular pool body 1, the pool wall and the pool bottom of which are made of steel plates. Such as figure 1 , 2 As shown, one side of the pool is provided with a vertical partition 2, and the partition divides the pool into a sedimentation zone a and a stirring zone b. The volume of the stirring zone b is 6-8 times the area of the precipitation zone a. There is a gap between the bottom end of the partition and the bottom surface of the tank body, so that the sedimentation zone and the stirring zone are connected to each other at the bottom.

[0022] A horizontal orifice plate 3 is provided at the waist of the sedimentation area a, and a cleaning water pump 4 is provided above the horizontal orifice plate 3 . The horizontal orifice plate separates the sedimentation area up and down to ensure that the upper water body is still and accelerate the sedimentation. The cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com