Zero-emission and zero-pollution concrete manufacturing technology

A manufacturing process and concrete technology, applied in clay preparation devices, mixed operation control, mixed operation control devices, etc., can solve the problems of no dust-proof and dust-suppression facilities, random discharge of production wastewater, affecting people's life and health, etc. The effect of comprehensive utilization, solving the problem of construction sand resources, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

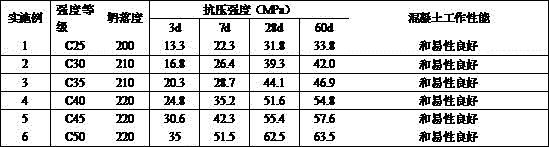

Examples

Embodiment Construction

[0022] In order to further describe the present invention, the zero-emission and zero-pollution concrete manufacturing process of the present invention will be further described below in conjunction with examples.

[0023] A zero-emission, zero-pollution concrete manufacturing process, comprising the following steps:

[0024] (1) Short process sand making process

[0025] S1: Select iron-containing industrial tailings that meet the national standards "construction sand" and "construction gravel and pebbles" and place them in a closed / semi-closed working environment, and transport the iron-containing industrial tailings to the electromagnetic Feeding machine; at the same time, spray and dust remove the working environment of the electromagnetic feeder through the spray dust removal device installed above the working area.

[0026] Since the electromagnetic feeder adopts vibration feeding during the feeding process, the stone powder in the material will generate dust due to vib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com