Composite vamp fabric with gradient functions and preparation method thereof

A gradient function, composite cloth technology, applied in chemical instruments and methods, shoe uppers, footwear, etc., can solve the problems of harsh production and use conditions, poor physical properties and chemical resistance, and achieve lower shoemaking costs and faster moisture absorption. The effect of good drying and improving the quality of shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, preparation functional sewing non-woven fabric

[0042] (1) take by weighing the nylon fiber of 50 mass parts, the hemp fiber of 30 mass parts and the polypropylene fiber of 20 mass parts as the compound material of preparing hydrophobic layer I;

[0043] Take by weighing the nylon fiber of 40 mass parts, the hemp fiber of 40 mass parts and the polypropylene fiber of 15 mass parts as the compound material of preparing hydrophilic layer;

[0044] Weigh 50 parts by mass of nylon fiber, 30 parts by mass of hemp fiber and 20 parts by mass of polypropylene fiber as a mixture for preparing the hydrophobic layer II.

[0045] The fibers weighed above are opened and carded to obtain a lap, and the lap is needled and combed to obtain a hydrophobic fiber web I, a hydrophilic fiber web and a hydrophobic fiber web II. Lay the above-mentioned hydrophobic fiber net I, hydrophilic fiber net and hydrophobic fiber net II, and obtain a non-woven fabric in which the hydropho...

Embodiment 2

[0068] Embodiment 2, preparation vamp composite cloth

[0069] Blend polyester staple fiber, hemp fiber and cotton fiber to obtain single yarn, wherein the mass ratio of polyester staple fiber, hemp fiber and cotton fiber is 50:25:25; The yarn is plied to obtain ply yarn, and then woven fabric is obtained through weaving, which is the shoe fabric, wherein the mass ratio of blended staple fiber to polyester long yarn is 45:55. The gram weight of the obtained shoe fabric is 420 grams / m 2 , a width of 150 cm.

[0070] The above-mentioned obtained shoe material and the seam-bonded non-woven fabric prepared in Example 1 (the grammage is 250 grams / m 2 ) use PUR hot-melt adhesive for paste dot compounding, in which the end face with the largest hemp content in the shoe lining is compounded with the shoe fabric, the controlled compounding temperature is 120°C, the pressure is 4.0ba, and the amount of glue is 20g / m 2 .

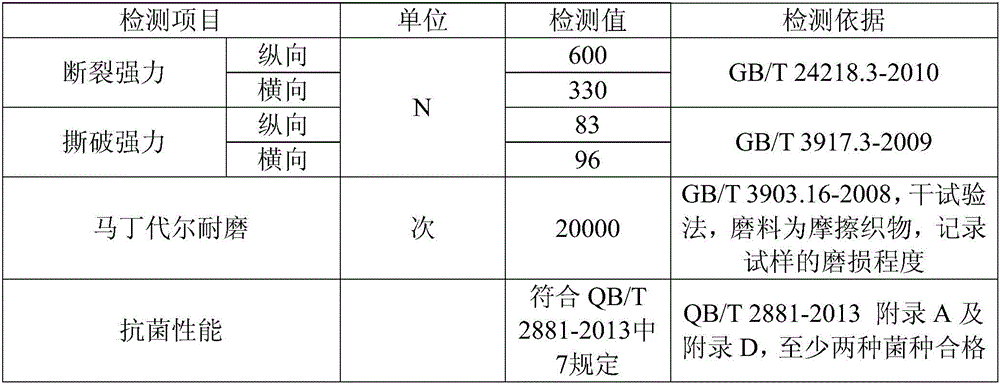

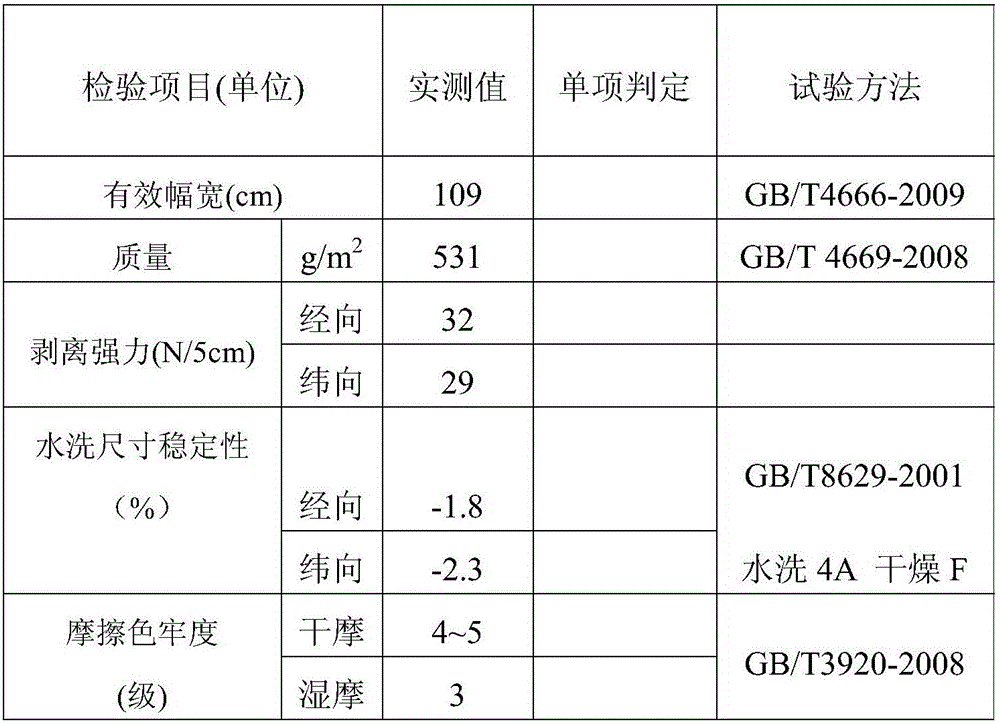

[0071] Some physical and chemical parameters of the shoe uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal breaking strength | aaaaa | aaaaa |

| Weft breaking strength | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com