Anti-collision and anti-freeze composite structure with concave-convex point type

A composite structure, concave-convex point technology, applied in ship parts, ships, ship cleaning devices and other directions, can solve the problems of large devices, difficult device implementation, complex structures, etc., to achieve simple construction operations, improve space utilization, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

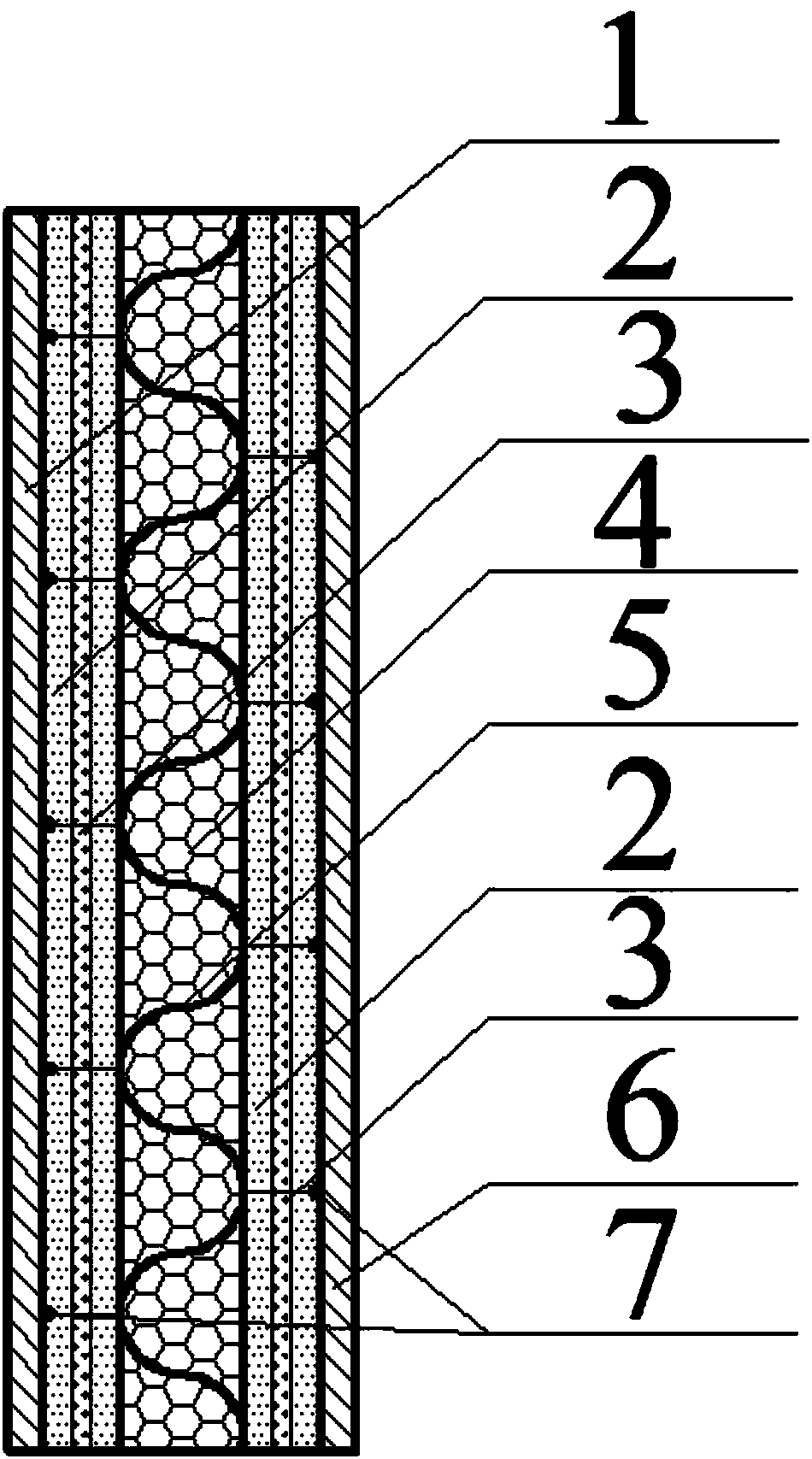

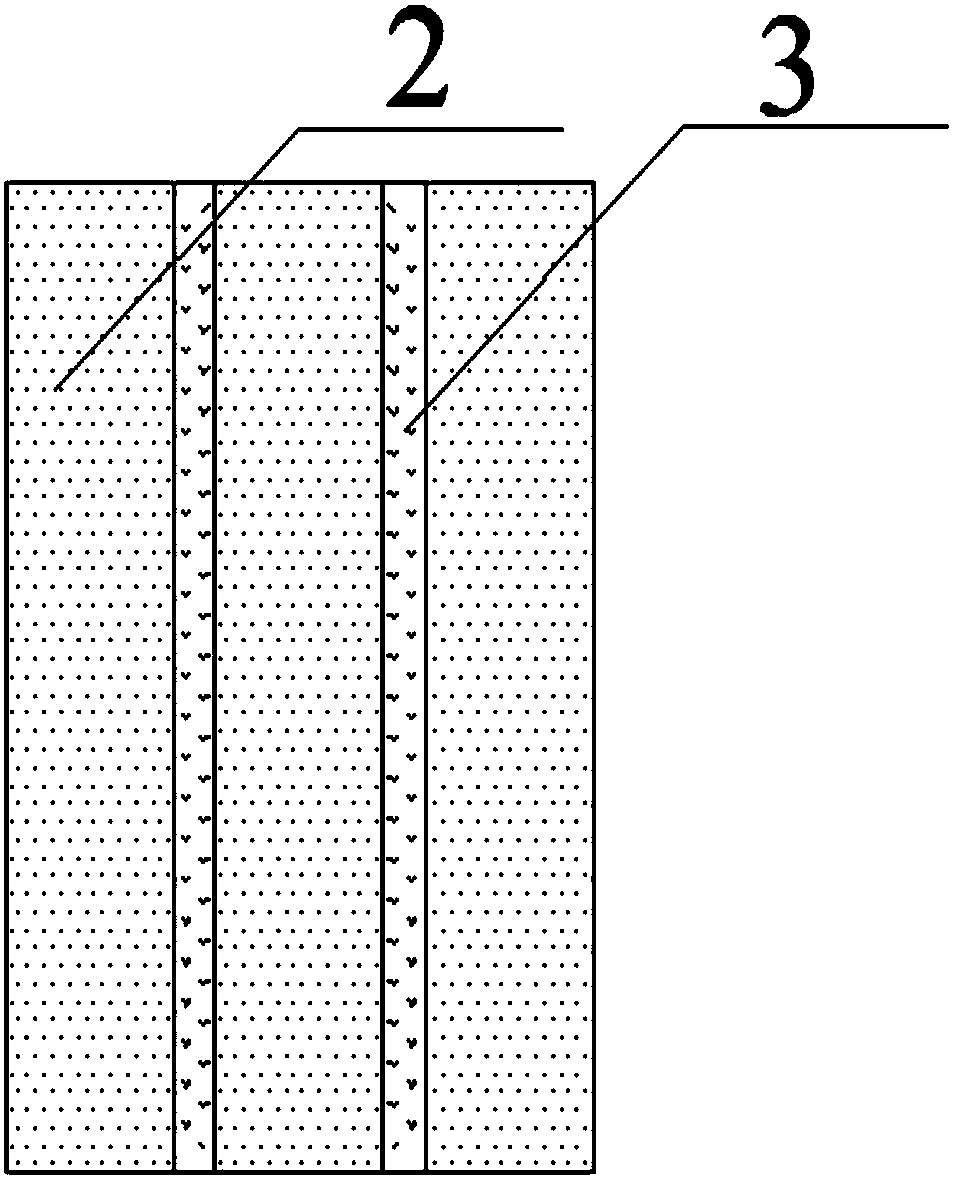

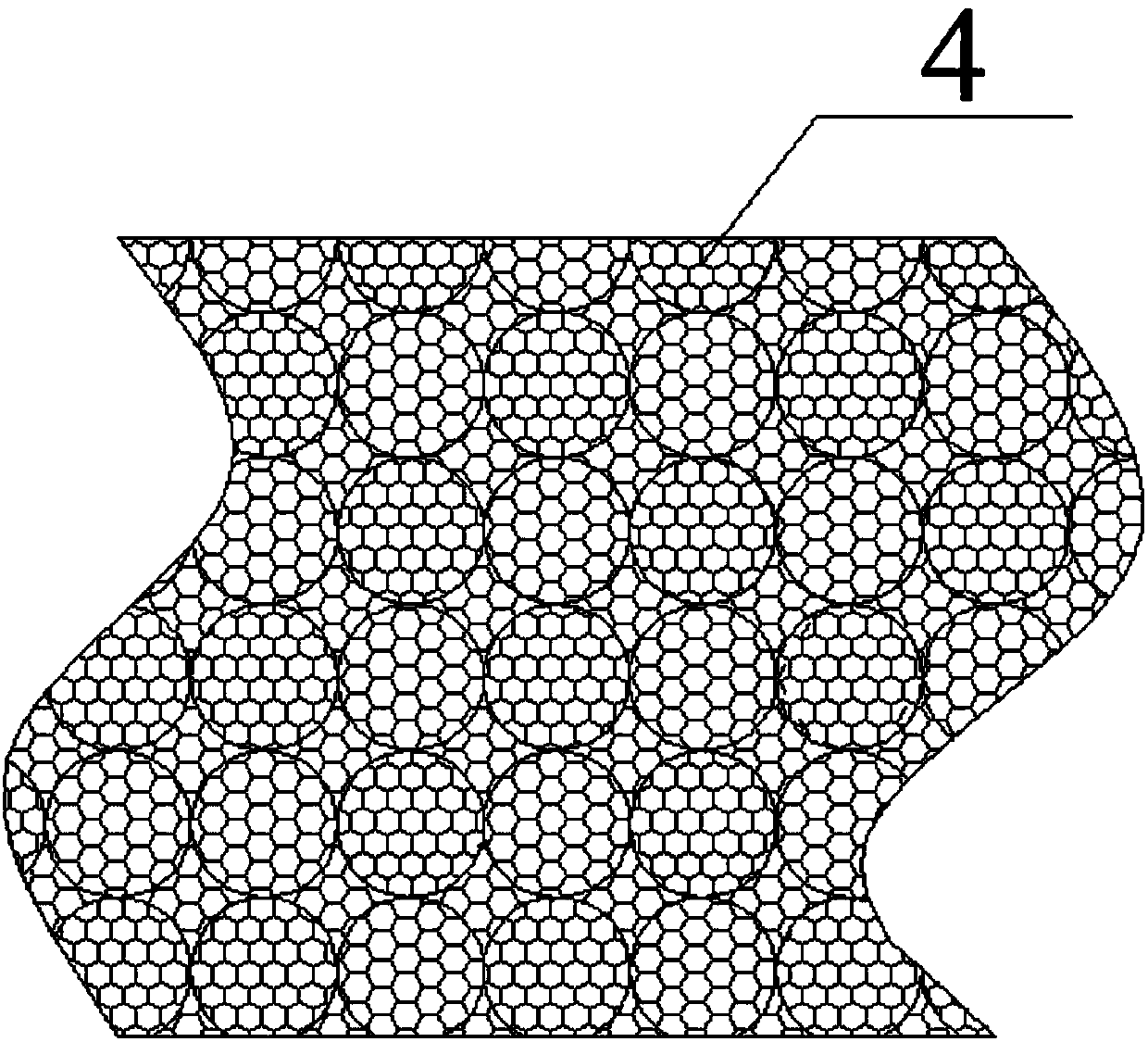

[0023] Such as Figure 1-Figure 5 As shown, a concave-convex point type side anti-collision and anti-freezing composite structure includes a ship side inner plate 1 and a ship side outer plate 6; the ship side inner plate 1 is sequentially arranged in the direction of the ship side outer plate 6 There is a second buffer cushion layer, a concave-convex type anti-collision plate 5 and a first cushion cushion layer; the first cushion cushion layer and the second cushion cushion layer are separated by a multilayer rubber cushion layer 2 and a multilayer composite steel wire mesh layer 3 Composite layer set. The composite layer of the rubber pad 2 and the composite steel wire mesh layer 3 arranged at intervals has more than two layers, and is laid layer by layer according to the actual size until it is completely filled.

[0024] The rubber cushion layer 2 and the composite layer of composite steel mesh layer 3 arranged at intervals are connected and fixed by a cylindrical connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com