Semi-aromatic copolyamide resin and copolyamide molded composition consisting of same

A technology of polyamide molding and copolyamide, which is applied in the field of engineering plastics and can solve the problems of semi-aromatic polyamides being rare in the public domain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4 and comparative example 1-7

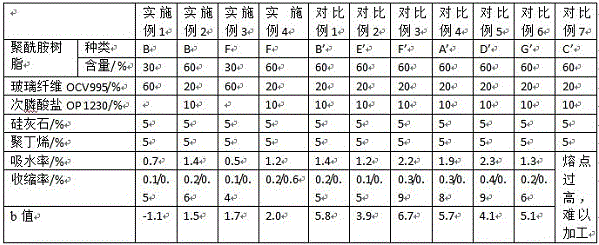

[0130] Examples 1-4 and Comparative Examples 1-7: Preparation of polyamide molding compositions

[0131] According to the formula in Table 2, the semi-aromatic copolyamide resin, additives and / or other polymers are mixed uniformly in the high-speed mixer, and then fed into the twin-screw extruder through the main feeding port, and the reinforcing filler is fed through the side of the side feeding scale. Feed; extrusion, water cooling, granulation and drying to obtain a polyamide molding composition. Here, the extrusion temperature was set to be 20°C or higher than the melting point.

[0132] Table 2 Each component in the following table is a weight percentage (%)

[0133]

[0134] As can be seen from Table 2, the polyamide molding composition prepared from the semi-aromatic copolyamide resin prepared in the present application has significantly improved color properties, low water absorption and good dimensional stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com