A lifting type descaling device for forged products

A descaling and lifting technology, which is applied in the field of lifting descaling devices, can solve the problems of slow descaling speed, incomplete descaling, and inability to control the lifting well, so as to achieve fast descaling speed , Thorough and easy-to-operate effect of descaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

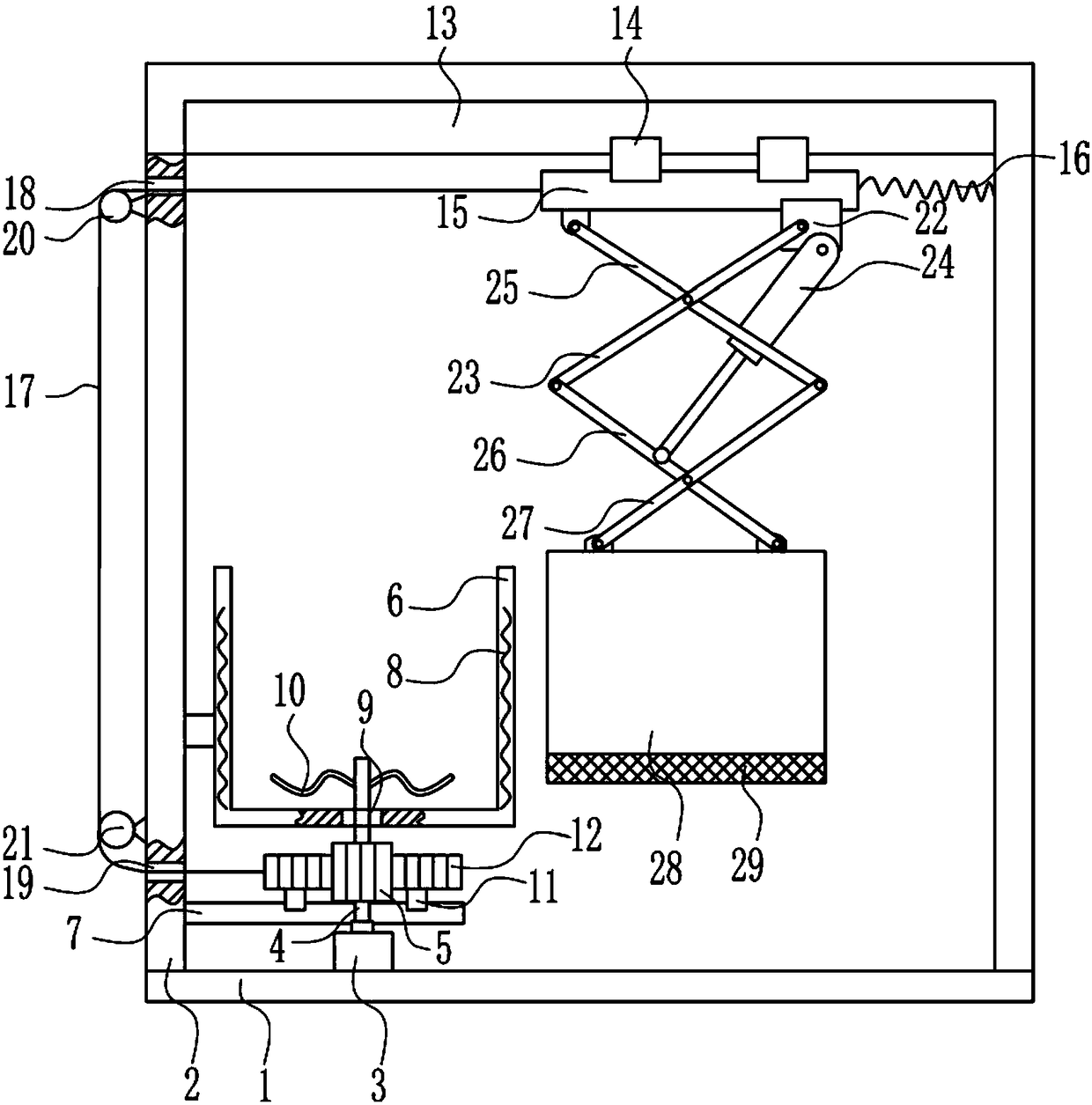

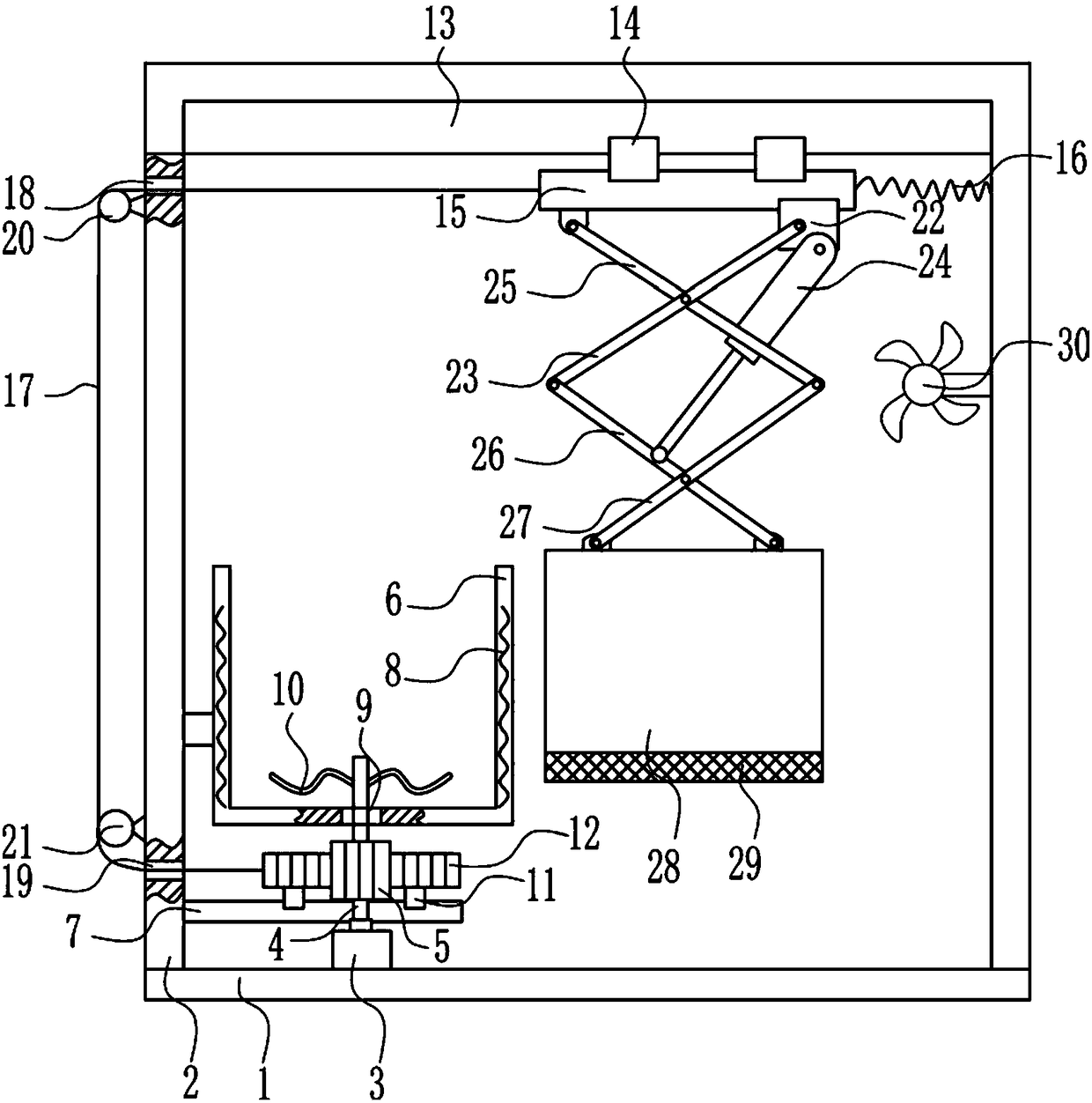

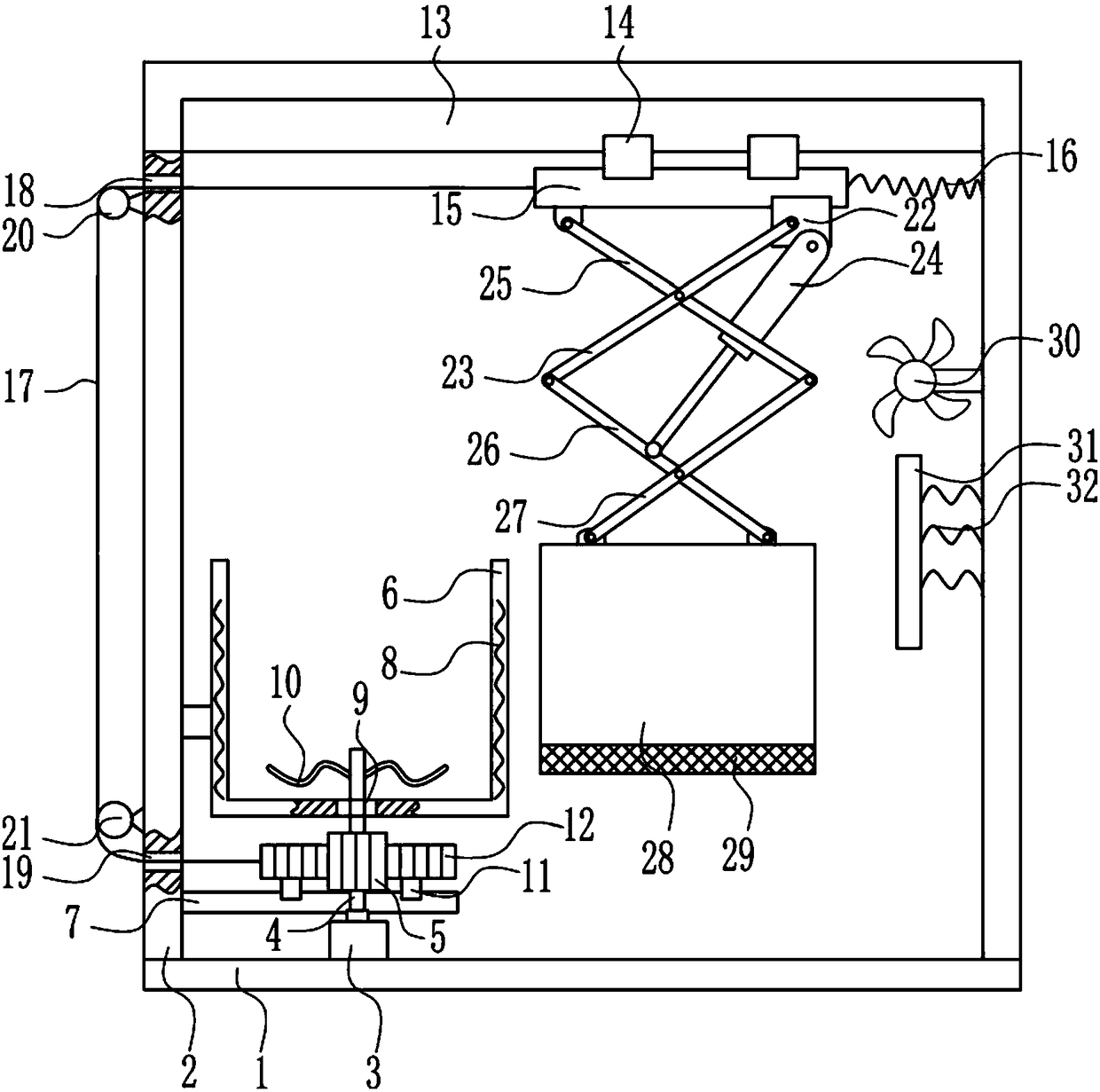

[0027] A lifting type descaling device for forging products, such as Figure 1-3 As shown, it includes a bottom plate 1, an n-type frame 2, a first motor 3, a rotating shaft 4, a gear 5, a processing box 6, a first slide rail 7, an electric heating wire 8, a stirring rod 10, a first sliding block 11, and a rack 12. The second slide rail 13, the second slide rail 14, the third slide rail 15, the first spring 16, the drawstring 17, the first pulley 20, the second pulley 21, the third slide 22, the first connecting rod 23 , The cylinder 24, the second connecting rod 25, the third connecting rod 26, the fourth connecting rod 27, the placing box 28 and the mesh screen 29, the bottom plate 1 is provided with an n-shaped frame 2, and the bottom plate 1 is installed in the n-shaped frame 2 The first motor 3, the output shaft of the first motor 3 is connected with a rotating shaft 4, the rotating shaft 4 is provided with a gear 5, the inner left wall of the n-shaped frame 2 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com