A construction method for an assembled slab track structure

A construction method and a technology for assembling boards, which are applied in the directions of tracks, roads, ballast layers, etc., can solve the problems of high labor intensity of cast-in-place ballast beds and links that affect the progress of track construction, and achieve obvious social and economic benefits and save labor. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with specific embodiments.

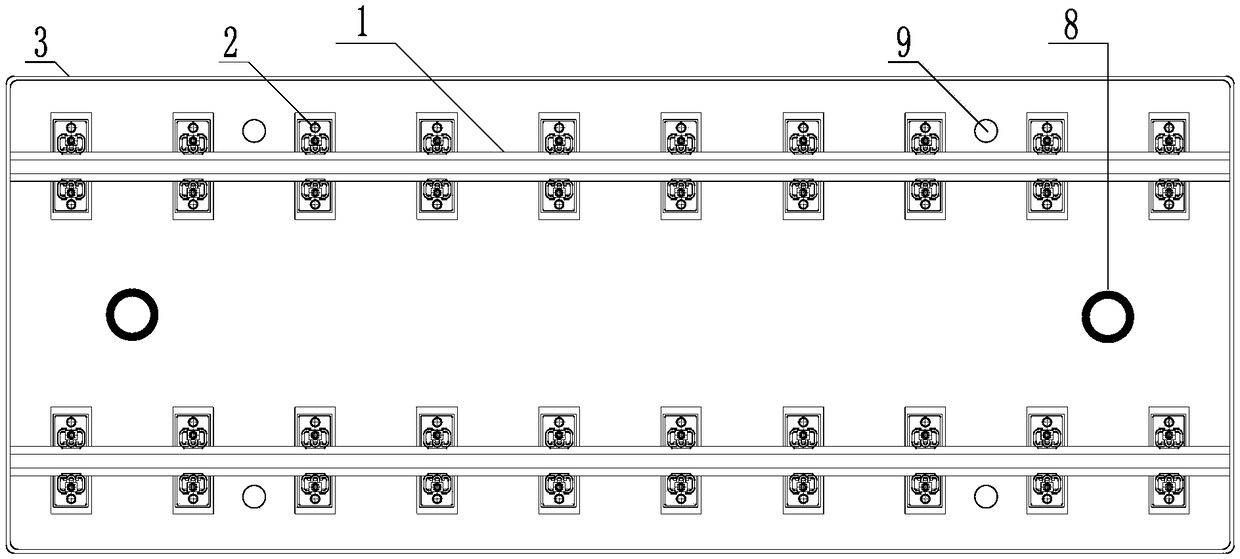

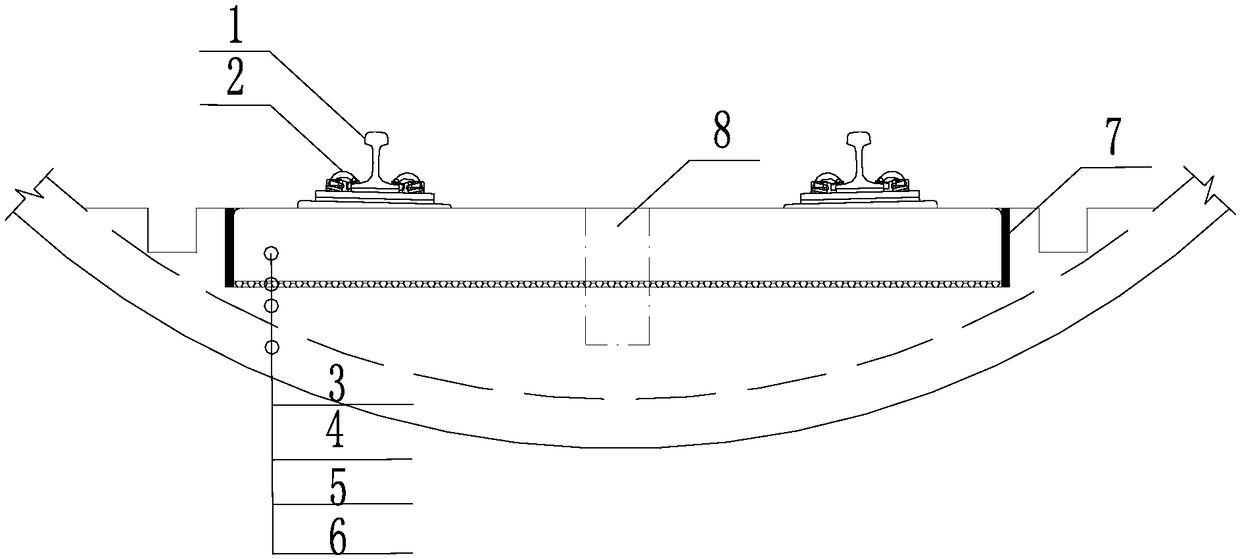

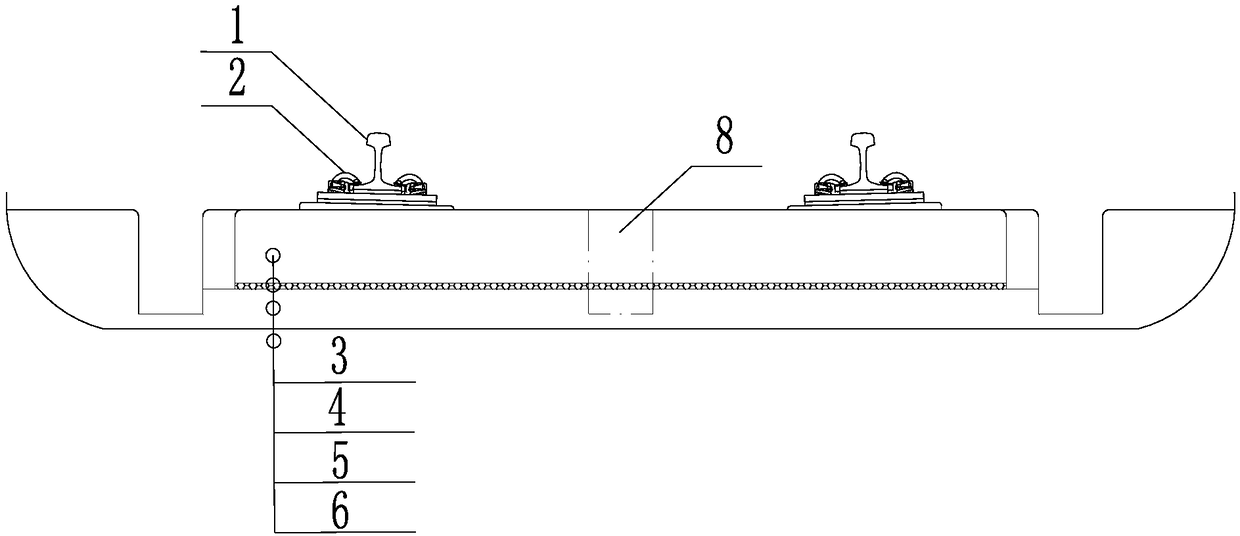

[0047] The invention relates to a track structure system assembled with prefabricated track slabs, see Figure 1 to Figure 5 , assembly plate track structure, including rail 1, fastener 2, track plate 3, viscoelastic cushion 4, base 5, track foundation 6, isolation layer 7, limit pin 8, lifting point 9, base 5 is located on the track On the foundation 6, the viscoelastic cushion 4 is located between the track slab 3 and the base 5, and there is no post-cast leveling layer on the track slab 3; structures are arranged on both sides of the track slab 3, such as drainage ditches or concrete filling and track The slabs 3 are flush, and an isolation layer 7 is set between the track slab 3 and the above-mentioned structures. The track plate 3, the viscoelastic cushion layer 4, the base 5, and the track foundation 6 are detachable assembly structures with each other, and are not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com