A track intelligent cleaning mechanical claw based on parallel mechanism

A technology of intelligent cleaning and mechanical claws, which is applied in the field of rail processing, can solve the problems of poor cleaning effect of residual grinding iron chips, poor equipment stability, low work efficiency, etc., and achieve good high-pressure cleaning effect, large carrying capacity and uniform cleaning force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

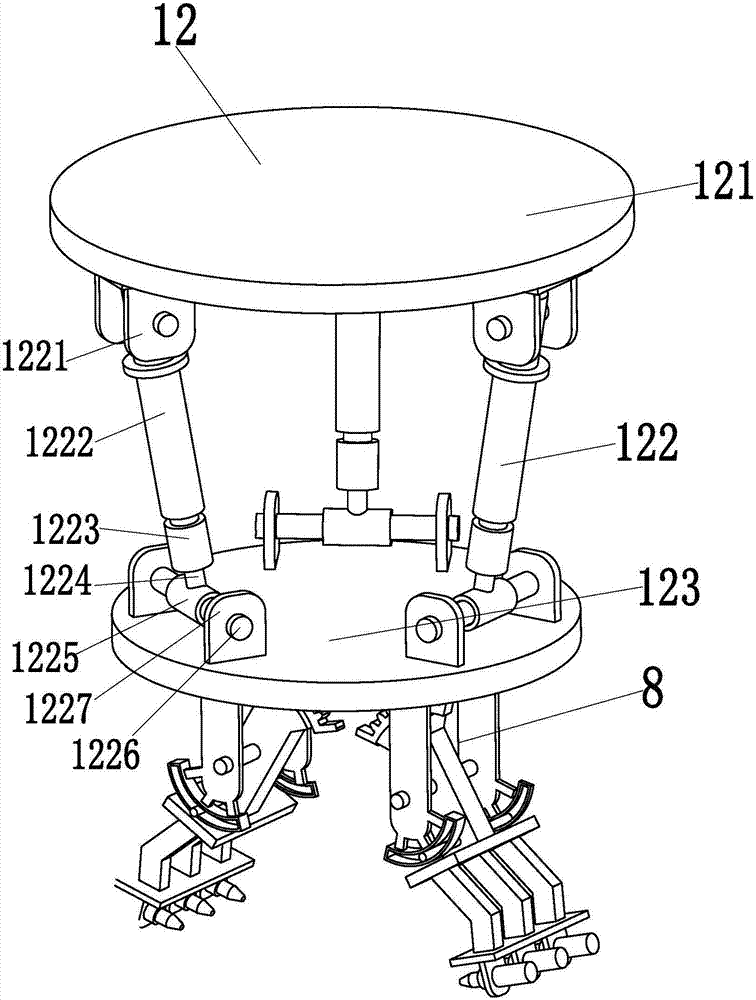

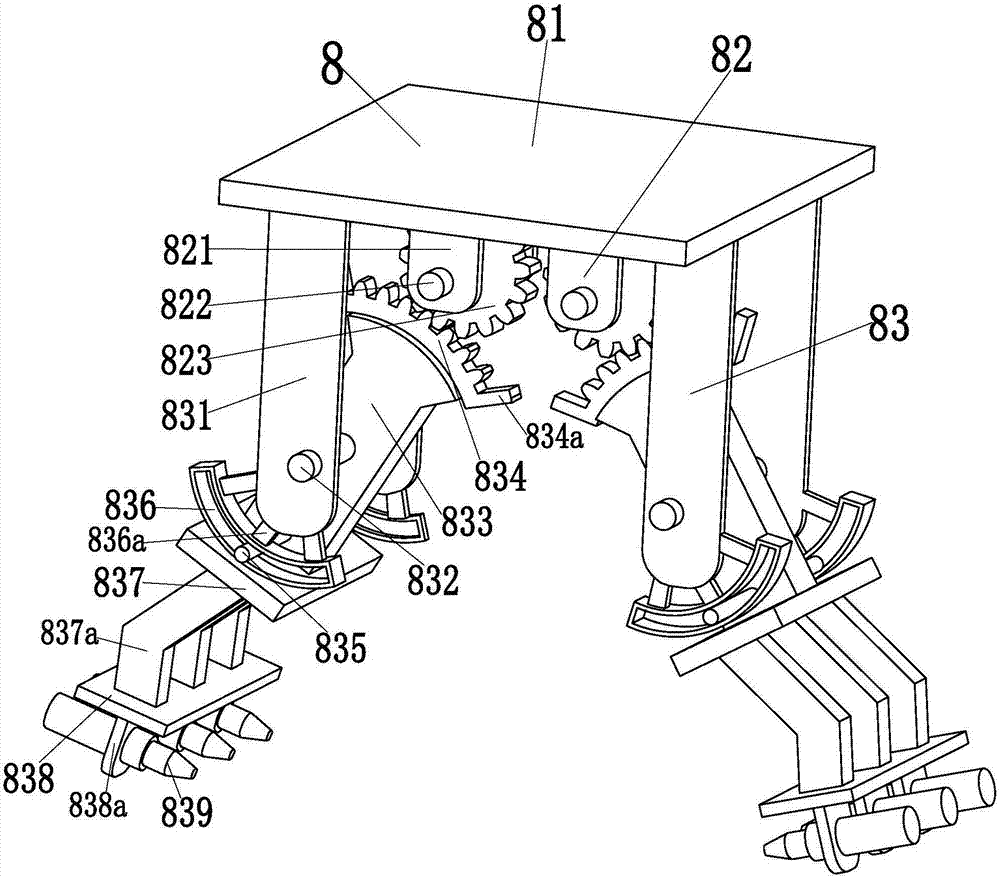

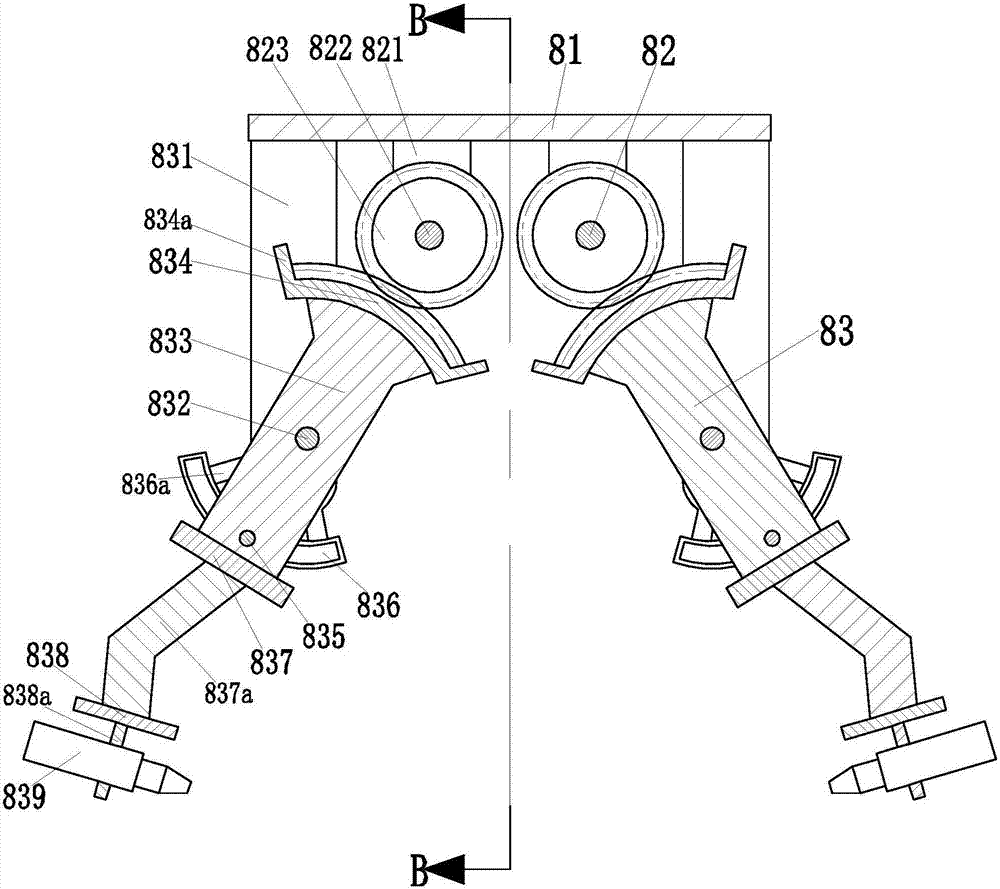

[0019] like Figure 1 to Figure 5 As shown, a track intelligent cleaning mechanical claw based on a parallel mechanism includes a parallel support mechanism 12, the parallel support mechanism 12 includes a fixed platform 121, and three parallel branch chains 122 are evenly installed on the lower end surface of the fixed platform 121 along the axis The lower end of each parallel branch chain 122 is equipped with a moving platform 123; the parallel branch chain 122 includes an ear seat 1221 welded on the lower end surface of the fixed platform 121, and a No. 1 hydraulic cylinder 1222 is installed on the ear seat 1221 through a pin shaft. The cylinder 1222 can rotate on the ear seat 1221. The top of the No. 1 hydraulic cylinder 1222 is threaded wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com