Large-diameter quickly-accomplished homogeneous cement-soil pile high pressure jet grouting micropore spouting nozzle group stirrer

A technology of cement-soil piles and high-pressure rotary spraying, which is applied to sheet pile walls, buildings, infrastructure engineering, etc. The difficulty of quality supervision and management, the effect of ensuring pile quality and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

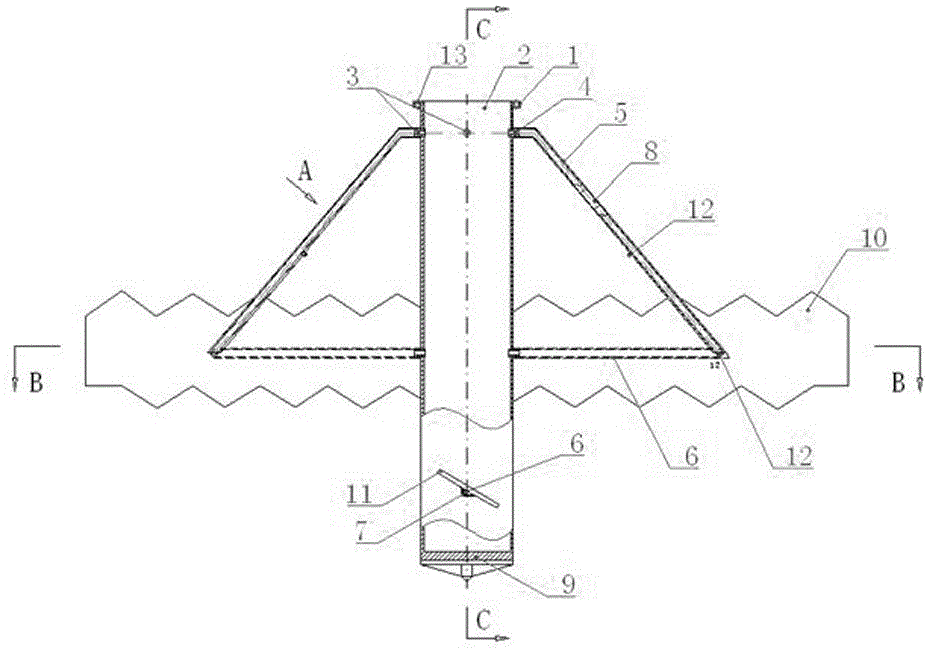

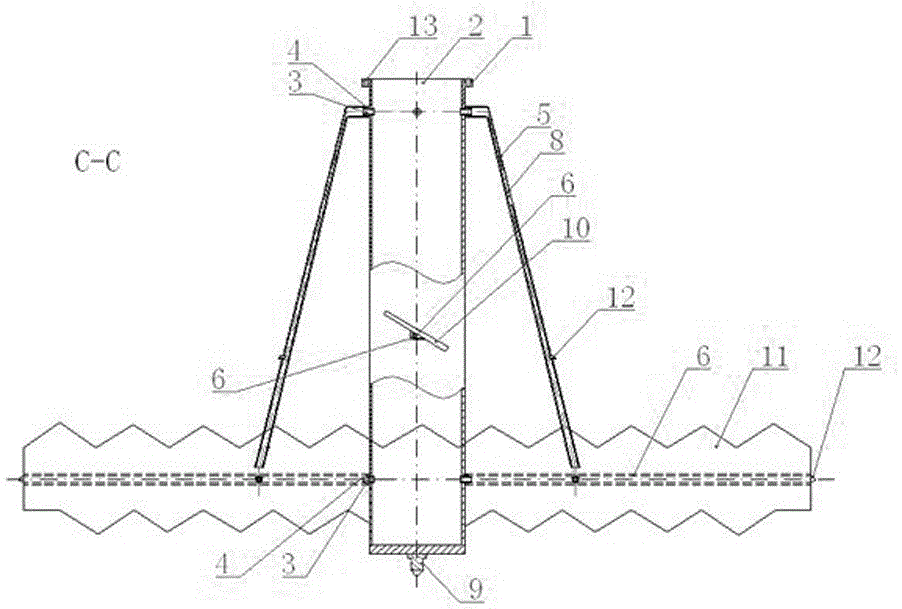

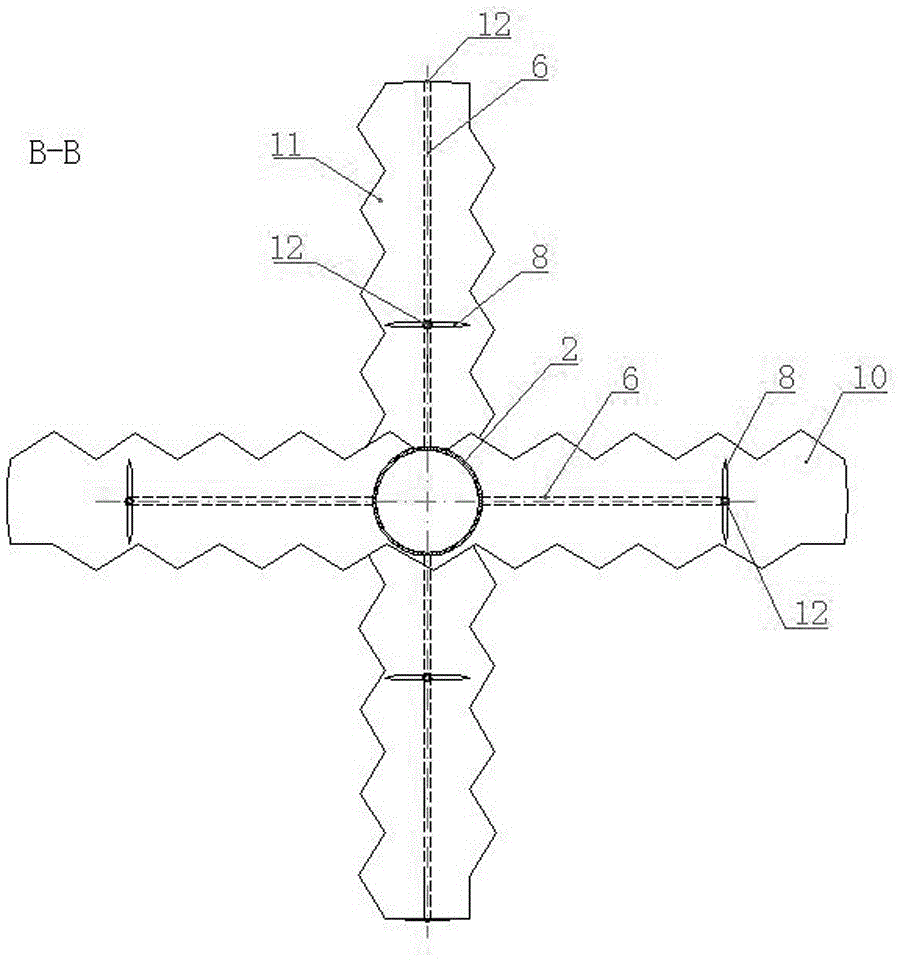

[0021] See Figure 1-Figure 5 In the present invention, the flange 1 is set on the top of the hollow grouting main pipe 2 of the agitator and the flange 1 set on the lower end of the hollow drill rod of the long auger, and the flange 1 is connected by bolts through numerous bolt holes to form a whole , The inner diameter of the flange 1 is the same as the inner diameter of the hollow drill rod of the long auger drill, and the flange 1 is provided with evenly distributed bolt holes 13. The hollow grouting main pipe 2 is provided with a flange 1 at its top, a fork pipe bleed hole 3 with an inner thread and an upper horizontal flat bayonet 10 are respectively provided on the wall of the hollow grouting main pipe 2 One end of the horizontal flat bayonet 11 and the lower layer is welded to the outer wall of the hollow grouting main pipe 2 at a certain angle (0°-55°) with the horizontal plane. Under the horizontal projection of the space, the upper and lower layers form a cross-shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com