Interlayer connecting joint

An interlayer connection and node technology, which is applied to building components, walls, floors, etc., can solve the problems of difficult to guarantee grouting quality, easy destruction of concrete, unfavorable steel connection, etc., and achieve the effect of convenient construction, convenient construction and convenient hoisting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The interlayer connection node of the present invention will be described in detail below with reference to the drawings and embodiments.

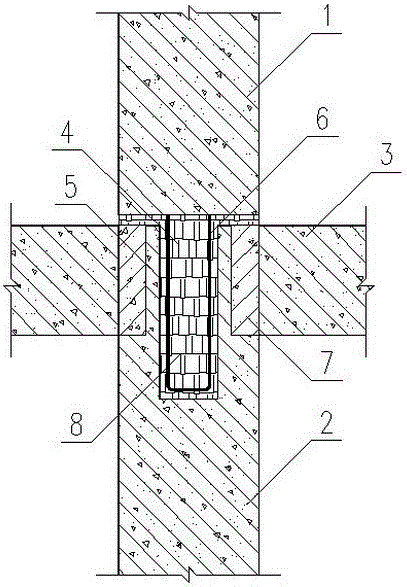

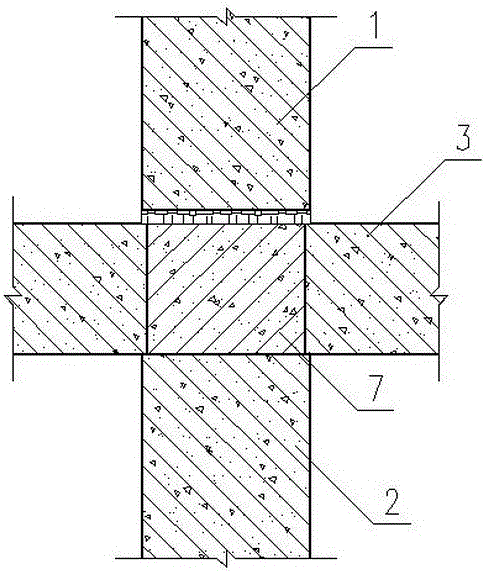

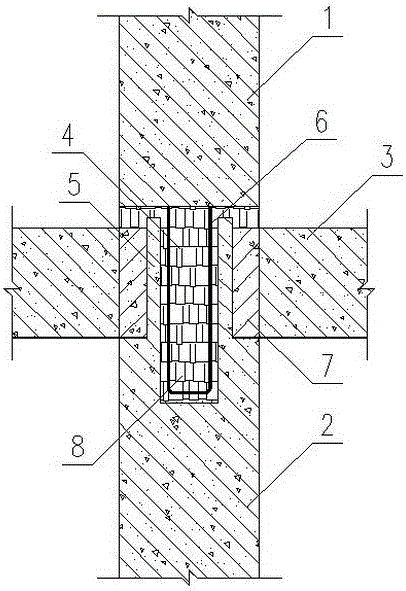

[0047] An embodiment of the interlayer connection node proposed by the present invention, such as figure 1 , figure 1 It is a schematic cross-sectional diagram of an interlayer connection node, and the cutting position is at the longitudinal hole position of the lower wall (the reinforcing bars not involved in the present invention are not drawn in the figure). The inter-layer connecting nodes include upper shear wall 1, lower shear wall 2 and prefabricated slab 3; the floor slab is prefabricated slab. The bottom of the upper wall 1 is pre-embedded with connecting steel bars 6, and the exposed part is U-shaped; the top of the lower wall 2 has a protrusion 5, and a longitudinal hole 4 is opened on the protrusion 5, and the protrusion 5 protrudes from the top surface of the lower wall 2 and the floor. The top surface is at the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com