Method for blasting centralized recovery lag jambs in several times

A pillar and concentration technology, applied in the field of open-field mining, can solve problems such as waste of resources, achieve efficient recycling, and improve operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below through specific embodiments and in conjunction with the accompanying drawings.

[0015] The recovery object is the stranded ore pillar in the goaf of the polymetallic mine in the Xiaotieshan mining area of Baiyin City, Gansu Province. The rock hardness is about 6-8.

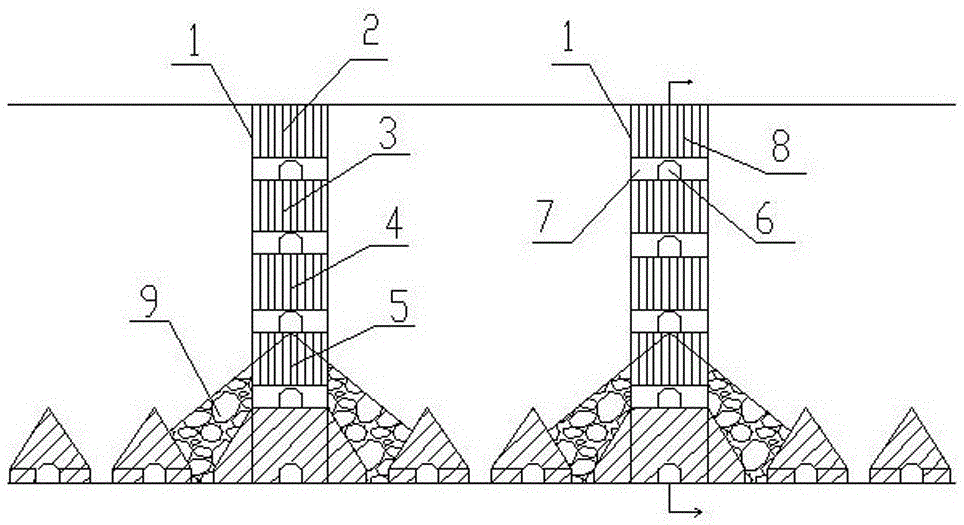

[0016] (1) Segmentation: select two adjacent ore pillars 1 as a blasting unit in the mined-out mine house through the ventilated pedestrian patio outside the vein, such as figure 1 As shown, from the top of the pillar 1, the pillar 1 is divided into four sections in the height direction, each section is 10m, and from top to bottom are the first section 2, the second section 3, the second section The third segment 4 and the fourth segment 5.

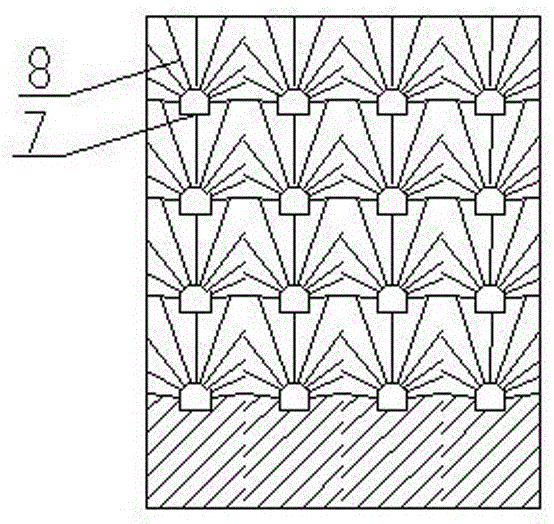

[0017] (2) Arrange the blasting structure: such as figure 2 As shown, a rock drilling roadway 6 is excavated along the length direction of the ore pillar 1 at the lower end of each segment and in the center o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com