Fixing device for explosive columns of solid rocket engine

A technology of solid rockets and fixing devices, which is applied in the direction of rocket motor devices, machines/engines, jet propulsion devices, etc. It can solve the problems of research on parts without charge, the central axis of the rotary body of the charge column cannot be stably parallel, and the curve of engine pressure and thrust Deviation and other problems, to achieve the effect of accurately testing ground pressure and thrust, reducing the probability of unstable combustion, and reducing the possibility of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

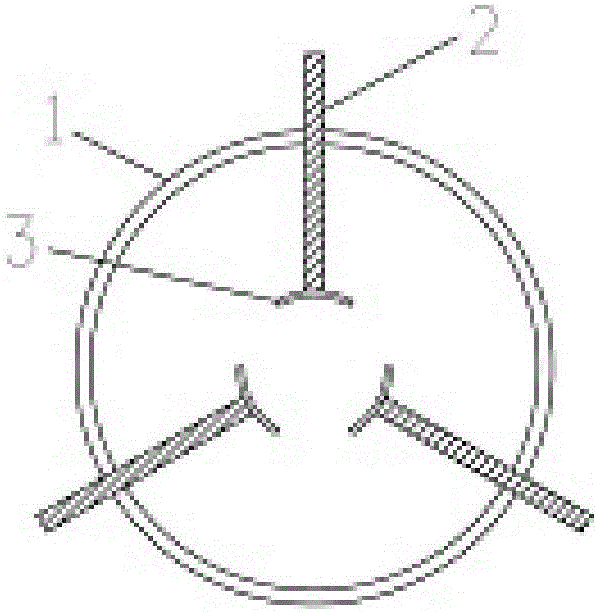

[0023] This embodiment is a solid rocket motor grain fixing device.

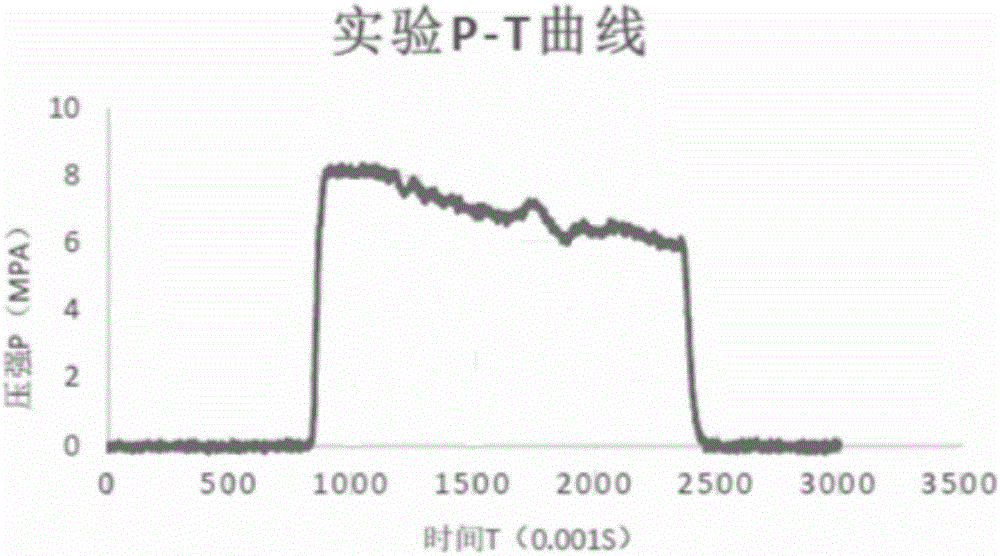

[0024] After the design of the solid rocket motor is completed, it is necessary to conduct ground static experiments to measure the pressure-time curve and thrust-time curve, and then perform data processing to check whether the technical indicators meet the design requirements. If it is not achieved, the design must be further modified, and ground experiments should be carried out again until the design requirements are met. In order to obtain the pressure-time curve and thrust-time curve of the engine, the measured pressure and thrust signals are converted into voltage signals through the pressure sensor and thrust sensor installed on the engine, and the voltage signal is amplified and saved by the computer data acquisition system . Since the output of the sensor is a voltage signal, and the experiment needs to obtain the thrust and pressure signals, that is, the actual physical quantity, the sensor used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com